Increased demand for fruit and vegetables across retail and foodservice channels is driving supply chains to invest in automation and other tools that make the transfer of product more efficient while reducing waste, according to Stöcklin Logistics. The company today said it is launching Stöcklin CasePicker to address the specific logistics challenges and opportunities now facing produce shippers.

“Until recently, varying types of containers were a major impediment to automated depalletization and subsequent direct palletization on pallets for each specific retail outlet,” stated Damaris Grütter, director of U.S. and Canada at Stöcklin.

“Conventional automated picking systems depalletized the entire pallet and separated the contents on trays in one initial step, which took a lot of extra time and increased the opportunity for product damage and waste,” she added. “The Stöcklin CasePicker addresses all of these pain points plus dramatically improves throughput performance.”

CasePicker offers modular food handling

“The Stöcklin CasePicker offers a completely automated solution for distribution centers serving hundreds of retail outlets,” said Laufen, Switzerland-based Stöcklin Logistics. It can operate in freshness zones ranging from 4°C to 14°C (39.2°F to 57.2°F) and up to 135,000 cases per day for fruit and vegetables, said the company.

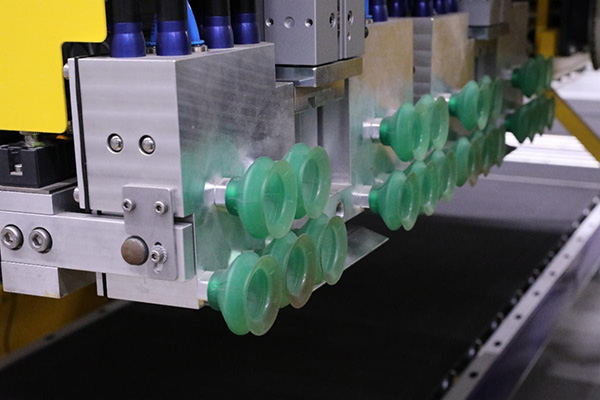

The new system includes a depalletizer with intelligent controls managing a gripper with a suction strip and underride plate to ensure gentle and reliable case picking, said Stöcklin. It added that, for the first time, the gripper allows different returnable and disposable containers to be picked immediately after one another.

In accordance with Stöcklin policy, the Stöcklin CasePicker is modular and scalable, the company claimed. Depending on the required performance, it can be upgraded by adding new modules and used with other Stöcklin equipment such as the FTS Eagle-Ant driverless lift truck for picking and conveying.

The modules are simple to integrate into existing buildings and structures, and they are also capable of docking with existing systems, Stöcklin said.

“The Stöcklin CasePicker ensures that only the intended goods are picked directly from the produce pallet for the retail-outlet pallet, which prevents unnecessary movement,” said the company. “In addition, the system speed depends on the order volume. This process optimization and variable utilization reduces the energy required in comparison to conventional solutions.”

Stöcklin promises scalability

“The Stöcklin CasePicker is completely scalable and ensures simple modular integration into existing distribution centers,” said Lothar Käufler, head of development at Stöcklin Logistics. “The number of workplaces can be reduced by two-thirds.”

“The remaining personnel experience a considerable improvement in the quality of their workplace, as well as a significantly healthier working environment,” he asserted. “This system, therefore, provides a truly employee-friendly alternative to the prior system of strenuous manual picking.”

For more than 85 years, Stöcklin Logistics said it has has delivered logistics innovations worldwide. The company said it supports its customers, from the planning and development phase through the delivery of complete, ready-to-use systems.

Stöcklin said its experience enables it to to offer conveying and storage systems for highly varying types of load carriers to improve its customers' competitiveness.

Article topics

Email Sign Up