From challenging work environments and the need for hygiene and traceability to labor shortages, the food processing industry can benefit from automation. Soft Robotics Inc. yesterday announced that it will be showing its mGripAI system for the first time at the International Production & Processing Expo next week in Atlanta. CHL Systems, a processing automation and design engineering leader, will also feature mGripAI in its booth.

“The protein industry has been hit the hardest by labor shortages, and the pandemic has made it even more difficult for food processors to keep up with demand,” said Mark Chiappetta, chief operating officer at Soft Robotics. “mGripAI enables robots to handle difficult bulk protein-handling applications, and we're excited to demonstrate this revolutionary technology for the first time to the largest protein processors in the world.”

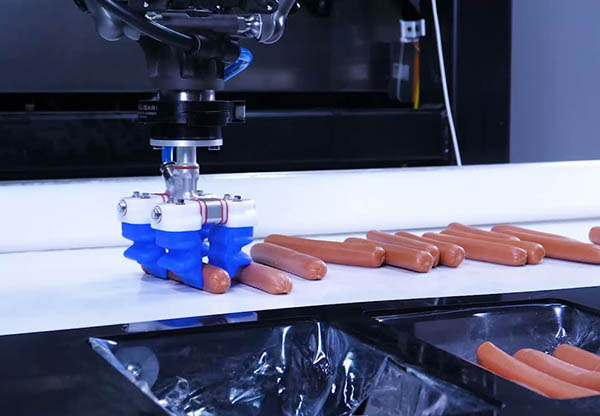

Soft Robotics designs and builds automated picking systems using proprietary soft robotic grippers, 3D machine perception, and artificial intelligence. The Bedford, Mass.-based company said its products enable machine builders to solve the hardest picking problems in food automation. Soft Robotics raised $10 million in a Series B extension last year.

Soft Robotics designs mGripAI for food industry

Soft Robotics said mGripAI enables industrial robots to tackle the complex processing tasks traditionally performed with manual labor. Its combination of 3D vision, AI, and IP69K-rated grippers provides robots with the hand-eye coordination of human workers, claimed the company.

Soft Robotics listed the following potential benefits of mGripAI:

- Reduced dependency on unavailable human labor

- Increased throughput

- Lower maintenance costs

- Safer products

- Reduction in food waste

“mGripAI opens up a host of new opportunities for CHL customers to address the challenges the industry is facing,” said Bryan Stout, sales manager at CHL Systems. “Our ability to implement or enhance their robotic systems using artificial intelligence is a game-changer. It enables us to offer advanced capabilities using better object tracking for moving and placing products, delivering results not previously attainable.”

See soft gripper at IPPE

The mGripAI will be on display at Booth C-10866 at the International Production & Processing Expo (IPPE) from Jan. 25-27, 2022, at the Georgia World Congress Center. CHL Systems will have mGripAI in Booth C-11449.

Founded in 1957, CHL Systems designs, builds, and installs automation equipment to move materials, make products, and pack merchandise. The Souderton, Pa.-based company said it can help customers overcome staffing limitations, outdated technology, and bottlenecks in production systems feed their communities.

Soft Robotics' flagship mGrip soft gripper will also be featured during IPPE in the booths of partners including CHL Systems, Ensight Solutions, FANUC, Harpak-Ulma, JLS Automation, Quest, and Staubli Robotics.

Article topics

Email Sign Up