To say there’s a lot going on with autonomous vehicle development is an understatement. There’s the vehicles themselves, which include LIDAR, radar, a vast array of sensor technologies, and the sophisticated artificial intelligence algorithms that power the autonomy. There are the smart cities in which the cars will interact as part of their excursions as well as a sophisticated ecosystem of suppliers all collaborating on various aspects of a solution.

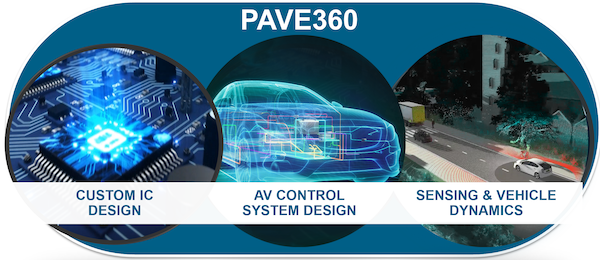

For everything to come together in a timely and cost-effective fashion, there’s no question, simulation must be a foundational building block for development. While various players leverage different simulation tools for specific aspects of self-driving car designs, Siemens PLM Software has just released PAVE360, a validation environment for automotive chips that creates a digital twin to simulate the entire complex ecosystem, not just the next-generation silicon.

“The automotive industry has been focused on a mechanical and electromechanical approach to solving problems—things where model-based system engineering is an effective solution,” says David Fritz, global technology manager for automotive at Siemens PLM Software. “Yet as soon as you get into the complexity of tossing in AI and converged ECUs (electronic control units), it reaches the point where a different approach needs to be applied.”

As a complete, closed-loop simulation platform, PAVE360’s different approach hails from the smart phone industry, which has employed similar verification and validation processes for some time. Using technology from its acquisition of Mentor Graphics, along with other pieces of its simulation portfolio, Siemens PLM Software has built a verticalized simulation solution that covers the entire spectrum, from chip design to aligning with players involved in smart cities. “We are now bringing the technology behind the validation and verification processes that were fine tuned to smartphone design over the last decade to automotive,” Fritz says.

Holistic Digital Twins

Specifically, PAVE360 extends digital twin simulation beyond processors to include automation hardware and software subsystems, full vehicle models, fusion of sensor data, traffic flows, and the simulation of smart cities, through which the self-driving cars will travel. The platform is designed to support cross-ecosystem collaboration for designing and building custom silicon and software solutions that will power the new generation of autonomous vehicles.

PAVE360’s closed-loop validation capabilities cover the sensing/decision/actuating paradigm that is the heart of automated driving systems. The full digital twin, which scales from the individual blocks of IP in a system-on-chip (SoC) to the hardware and software comprising the SoC to the vehicle subsystems and through the deployment of the vehicle in smart cities, enables designers to test everything from silicon development to full vehicle validation in a virtual world. This approach is critical for autonomous vehicle design, Fritz maintains, because of the vast scale of complex scenarios that need to be tested. Estimates are that 8.8 billion miles of testing would be required to fully validate an autonomous vehicle, which is next to impossible so virtual validation needs to be evolved and widely embraced.

“Validation testing is more comprehensive than testing and creating a chip, where you might program a finite number of examples,” he explains. “What if the chip doesn’t behave the way you think when you put it into the vehicle? We’re taking the digital twin and making it holistic from the inception of the vehicle.”

To learn more about Siemens’ vision for simulation and virtual validation in the development of autonomous vehicles, check out this video.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up