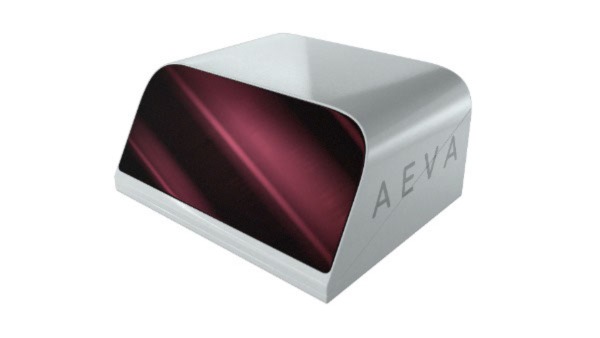

Aeva Technologies Inc. and SICK Sensor Intelligence yesterday announced a strategic multi-year collaboration to use Aeva’s 4D lidar technology on a variety of systems used for industrial applications. The partnership starts with the Aeries II, Aeva’s 4D lidar system that has camera-level resolution and uses the company’s Frequency Modulated Continuous Wave, or FMCW.

The Mountain View, Calif.-based company introduced the Aeries II in February.

Aeva said its proprietary 4D perception technology provides up to 20 times the resolution of legacy sensors. That enables autonomous vehicles to see up to twice the distance, the company claimed. It also said its lidar technology has better dynamic range performance to perceive low and highly reflectivity targets within the same measurement without edge effects. That allows automated machinery to transition easily from indoor to outdoor operations.

The company said its mission is to bring the next wave of perception to a range of devices including automated driving systems, industrial robots, consumer electronics, health care devices, security devices, and more.

A strong partner on its side

Sick is also a technology company. It is based out of Waldkrich, Germany and makes a range of sensors and accessories. With more than 50 subsidiaries and equity investments as well as numerous agencies, SICK maintains a presence around the globe. In the 2021 fiscal year, SICK had more than 11,000 employees worldwide and a group revenue of around EUR €2 billion (U.S. $2 billion).

“We are pleased to partner with Aeva and work closely together to bring its FMCW technology to high performance industrial sensing applications,” said Dr. Niels Syassen, member of the executive board responsible for technology and digitization at SICK. “We are convinced that their unique approach to FMCW technology, which includes instant velocity detection and long-range performance, will provide new opportunities for us and our customers in a variety of industrial sensing applications where traditional time of flight lidar technologies are challenged.”

Because Aeva’s technology is immune to blooming and ghosting from retroreflectors, automated machines using Aeva’s 4D lidar will have clear perception when highly reflective objects such as safety vests, cones and tape are in the field of view of the sensor, Aeva said.

The technology detects low and highly reflective objects such as safety vests, pylons and adhesive tapes in the sensor's field of view. FMCW helps increase reliability and efficiency in demanding 3D applications.

“SICK is one of the foremost leaders in industrial sensing solutions and today’s partnership is a major step forward for the advancement of high performance and reliable FMCW-based sensing across a broad set of industrial applications,” said Soroush Salehian, co-founder and CEO at Aeva. “This strategic collaboration is a testament to the industry-leading performance and versatility of our unique 4D lidar technology for scaled deployment in industrial applications.”

Article topics

Email Sign Up