Pick-and-place robots are increasingly helping manufacturers around the world. Scape Technologies A/S today announced a partnership with machine tools provider Demek CNC OÜ and an order from hand tool producer HEYCO-WERK SÜD as it continues to serve the automotive industry.

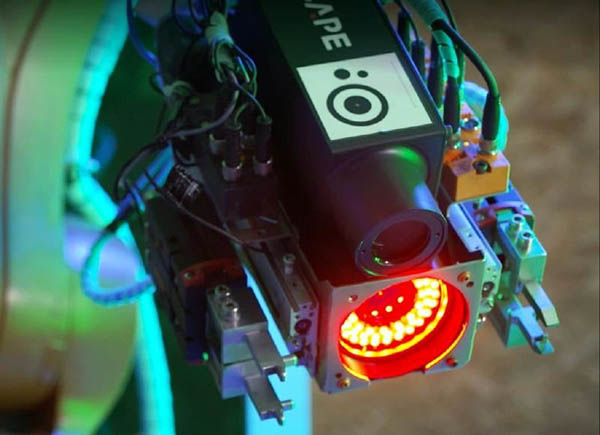

Founded in 2004, Scape Technologies has developed patented technology to recognize, pick and place parts. The Odense, Denmark-based company works with partners to build, market, and implement its SCAPE Bin-Picker system into production facilities for automakers such as Ford, Nissan, and BMW.

Scape Technologies recently launched the SCAPE Easy-Picker and SCAPE Mini-Picker, which it claimed are easy for small and midsize enterprises (SMEs) to install. It also released the SCAPE Package Picker for distribution and logistics applications.

In addition, Scape Technologies said that its systems include integrated components and software modules that can be connected directly to leading six-axis robot arms and collaborative robots from companies such as Universal Robots, ABB, FANUC, Kawasaki, and KUKA. The company is listed at Nasdaq First North Growth Market.

Scape expands offerings in the Baltic region

Scape Technologies said it has established a new partnership with Demek CNC OÜ, a Tallinn, Estonia-based provider of metal machine tools and complete automation solutions for the Baltic region. In addition a staff with decades of experience, Demek CNC said its key advantages are its competence, flexibility, and response speed.

The company's main clients are machining companies, but it also provides automation for the electronics, food, and lumber industries, among others.

“Demek CNC OÜ is very pleased to count among its new partners Scape Technologies—the most experienced manufacturer in the challenging field of bin-picking,” said Maitis Märss, a board member at Demek CNC OÜ. “In our opinion, the precision of their solution, as well as their reliability, is the future of the bin-picking market.”

“Demek CNC’s core competences and projects fits to SCAPE Bin-Picking Solutions, which enable cobots and industrial robots to perform tasks that would not otherwise be able to automate efficiently and cost-effectively,” said Henrik K. Nielsen, channel manager at Scape Technologies.

“The technology is used, i.e., for pick-and-place and bin-picking operations for automatic machine feeding, where benefits in the form of increased stability, reliability, and efficiency help to ensure high profitability in automatic handling of items,” he added.

HEYCO orders SCAPE Bin-Picking system

Tittling, Germany-based HEYCO-WERK SÜD is a part of the HEYCO Group, a development partner known for prototype manufacturing for the module and systems business. HEYCO Group said it has approximately 900 employees at sites in Germany, Ireland, Czech Republic, and the U.S. manufacturing high-quality and technically and economically mature components.

As the production of hand tools has expanded from metals to include plastic parts and forgings, HEYCO Group has become a leading supplier for both the automotive and automotive supplier industry.

The company plans to use the complete SCAPE Bin-Picker Solution for picking randomly placed metal parts in containers. After picking the part from the container, the SCAPE Bin-Picker will precisely deliver the part on a conveyor belt.

“This is the first SCAPE order from HEYCO, and it confirms our core competence and strong position in the robotic material handling domain,” said Frank Nüsken, general manager of Scape Germany. “The standardized SCAPE Bin-Picking concept enables a wide range of industries to implement flexible and reliable bin-picking solutions for handling parts which can optimize productivity and eliminate monotonous tasks and improving workers' ergonomics.”

Scape said the order from HEYCO-WERK SÜD does not change its expectations for the current fiscal year.

Article topics

Email Sign Up