When Modern Materials Handling (a sibling site to Robotics 24/7) is interviewing companies for a “System Report,” one of the questions we always ask is: What were your goals for the project? After all, most distribution teams have a bulleted list of three or four high-level goals for a project or a new facility. Typically, they are along the lines of increase productivity without increasing headcount or improve order fulfillment times by 25%.

Every now and then, we come across a company with a far-reaching vision for its operations that extends beyond pick and error rates. For instance, we covered Scandinavian retailer Varner, whose goal was “to build the best warehouse in the world” when it designed a highly automated warehouse in Sweden.

More recently, we spoke to Masashi Okabe, project manager and production engineer at SoftBank Robotics (SBR), and Taro Ito, the robot quality assurance/control and software lead for SBR. They have designed a new 600,000-sq.-ft. SB Logistics distribution center (DC) in Ichikawa City, Japan, about 10 miles from Tokyo.

Both companies are part of SoftBank Group: SB Logistics is a third-party logistics (3PL) provider for e-commerce fulfillment, and SoftBank Robotics is SoftBank Group’s robotics division.

DC design had to align with greater goals

When Okabe, Ito, and their team began to work on the design for picking and packing processes for the facility, key performance indicators (KPIs) and return on investment (ROI) targets were among the considerations to justify the investment in automation. So was the ability of the robots to handle packages in a way that meets the exacting quality standards of Japanese consumers, who expect even the transport packaging to arrive without blemishes. As we’ll see, that was no easy feat.

But, as the pair explained, the design was also intended to align with their organizations’ larger goals.

“SBR’s vision is to utilize ‘the power of robotics to benefit humanity,’” said Ito. “Based on this vision, SBR aims to become a global leader in robotics solutions.”

“In the field of logistics, SB Logistics’ vision is to be a world-class e-commerce fulfillment and automation integrator in the global market by 2030,” added Okabe. “The introduction of Berkshire Grey robots is a big step for us to realize that vision.”

Part of that vision includes the development of a lights-out facility, one in which the limited number of people present are primarily there for maintenance and supervision, not warehouse processes. They’re not there yet.

For instance, inbound receiving and outbound shipping are still manual. In addition, oversized and fragile items that cannot be handled by automation are stored, picked, and packed using conventional process.

But a significant and increasing percentage of SKUs in the facility is handled by automation, from the completion of receipt to the shipping sorter before they are manually loaded onto outbound trucks.

SB Logistics said the Ichikawa facility is the first e-commerce fulfillment center to completely automate the picking and packing process after receiving customer orders.

“Our ultimate goal is a completely automated warehouse,” Okabe said. He claimed that the technology to achieve full automation is available, but it can’t yet deliver the required ROI. “But I do believe in the coming years we will be able to reach that goal,” he added.

Trio advances automation

Developing a robotic system for the Ichikawa City facility brought together three organizations. SB Logistics provides 3PL services enhanced by artificial intelligence and automation. The multi-level Ichikawa distribution center is the first facility for the company, which plans to add more. It can provide same-day and next-day delivery to all of Tokyo.

SoftBank Robotics has already deployed tens of thousands of robots across the globe in a variety of industries, not just logistics.

In the search for technologies that might be right for the new facility, the team worked with parent company SoftBank Group. It also happens to be an investor in Berkshire Grey and introduced the company to the designers.

“The ability to work with SoftBank Group is a strength for us,” said Okabe. “They are looking at new technologies around the world, and with that connection, we get to know new technologies before our competitors.”

SB Logistics was established in 2019 with the goal of addressing order-fulfillment challenges with technology, according to Masayuki Ataka, chief operating officer of the company.

In an interview with Japanese media, he explained that Japan is experiencing the same shortage of warehouse and distribution center labor as other parts of the world, including the U.S. That’s because the work in conventional facilities is labor-intensive and requires people to walk long distances.

“We thought about automating the warehouse and first reducing the burden on the people working at the e-commerce and logistics site,” Ataka said. “As a result, the quality of service will improve and the cost [of logistics] will be stable. We envision a future in which both consumers and e-commerce businesses will be more satisfied” through the use of automation.

Efficiency, sustainabilty, and quality

The initial goal was to automate processes from ordering to shipping, with the rest taken care of by people. For now.

If you use the three-legged stool analogy, two legs of the stool were the development of a cost-efficient, high-throughput facility that could provide same-day and next-day service across Tokyo in the most sustainable way, while reducing the reliance on people.

As an example, the company is making efforts to reduce the size of shipping boxes by combining systems and packing machines. It uses almost no plastic cushioning material in packing. This leads to a reduction of packing materials and a reduction in carbon dioxide emissions.

The third leg, which is critical to the Japanese consumer, is quality, or the appearance of the package that is handed off to the consumer, including the transport package. In the U.S., we tolerate the occasional ding and dent in packaging, even consumer packaging, if the product we ordered looks great and works as expected when we remove it and put it to use.

That is not the case in Japan.

“Quality is super important in the Japanese market and for the Japanese customer,” said Ito. He cited the example of a product with a slight dent in the protective outer plastic packaging. “Our customer could return this item or complain about the quality of the delivery to the seller, who would be our customer,” he said.

Ichikawa facility adds robots

The Ichikawa facility manages 50,000 SKUs and an average of 2 million units on behalf of its clients, pushing an estimated 5,000 pieces per hour through the shipping sorter located on a mezzanine level. The facility operates one shift per day, seven days per week.

At present, orders placed by 7:59 a.m. can be delivered the same day in all of Tokyo’s 23 wards. Orders placed by 3:00 p.m. will ship that day, typically for next-day delivery.

While lights-out automation is the goal, bringing automation into the facility was a multi-step process. SB Logistics opened as a conventional distribution center.

“No machines were installed at the time of the launch,” said Okabe. “We needed to get the service up and running, so we started with manual operations.”

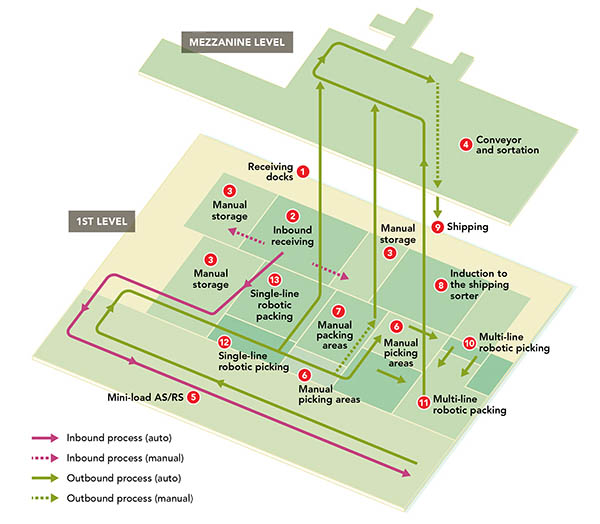

The implementation of automation got under way after the facility was operational. Automated storage was the first step. A conveyor system delivered storage totes from receiving to a mini-load automated storage and retrieval system (ASRS). Before the robots, the mini-load delivered totes to goods-to-person picking stations.

Next was the installation of a conveyor system and shipping sorter on a mezzanine to direct orders ready for delivery to the shipping area. Once there, packages are placed onto roller cages that are loaded onto trucks for delivery.

SBR researches robotics providers

With conveyor, sortation, and the ASRS in place, the next step was to automate picking and packing. SBR worked with SoftBank Group to find a robot provider.

“They have connections with cutting-edge technology companies that can be used in logistics,” noted Okabe. While working with the SoftBank Group on the robots, SBR conducted its own research for automated packing equipment in Japan, Europe, and North America.

The criteria for the picking and packing system was simple, but exacting. The robots and other equipment had to handle tens of thousands of SKUs, since more than 50,000 products are registered with Ichikawa.

In addition to meeting throughput requirements and exacting quality standards, the system had to meet Japanese safety standards and regulations related to earthquakes and natural disasters.

Another challenge was integrating SBR’s warehouse management and controls systems with the robotic operating system to communicate with the robots. Okabe said it didn’t take long to select Berkshire Grey.

“We sent them some hard-to-handle SKUs for testing, and when we checked the KPIs, the performance of the robots was better than we expected,” he recalled.

Testing and trials

Along with fine-tuning the robots to develop a touch soft enough to minimize damage, the two teams had to design the goods-to-robot work cells. To do so, Berkshire Grey built an Ichikawa-like test environment at its headquarters in Bedford, Mass.

Initially, Okabe was able to visit to participate in the design; then came COVID-19. From then on, that work took place remotely using video chats.

Finally, the team established milestones to audit the performance of the system, such as the ability to pick representative SKUs before going live. Addressing those issues during a pandemic, even with video chats, wasn’t easy, especially those related to quality.

Along with the pandemic-induced separation, the SBR and Berkshire Grey teams had to contend with time differences, as well as language and cultural differences. Okabe said he believes the rapport his team established with the robotics supplier allowed them to improve the quality of the processes as they reviewed weekly test picking results.

“Through this process, we were able to reaffirm Berkshire Grey’s high level of technology, speed of improvement, and our desire to release something that is actually useful to the world,” he said.

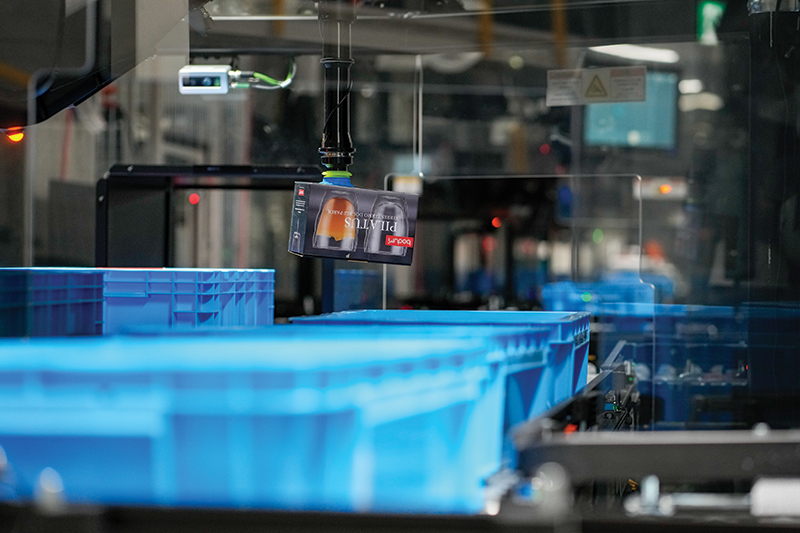

As designed, automation takes over once items have been received into a storage tote and conveyed to the ASRS. Single-line orders are picked directly into the shipping container, which is then conveyed to an automatic pack station where the order is finalized and sealed before the parcel is sorted to shipping.

Multi-line orders are batch-picked by the robots from donor totes. Order totes are then conveyed to pack stations where a robot picks and places items from the various order totes into a shipping container. In all, the facility uses four different types of packing machines to handle the variety of SKUs and orders.

For now, receiving remains a manual operation. Bulky and fragile items are manually picked and packed. And in receiving, associates load outbound parcels onto roller carts that are then rolled onto delivery trucks.

“Associates are still needed for some operations,” Okabe said. “Since we have a great deal of diversity in our inbound parcels, we have to be able to change our processes to meet the needs of our customers. However, automation reduces our reliance on labor and lowers our operating costs. These are big steps toward full automation.”

Inside SB Logistics

Going live

The system went live in April 2021. Once again, the novel coronavirus intervened. Since the system involved both Japanese and non-Japanese materials handling and automation suppliers, the closure of Japan’s border created barriers. Non-Japanese suppliers couldn’t send foreign-based engineers to help with installation.

The robotic solution was supported by a Japanese-based team. “Despite all of the challenges, we successfully managed the integration of the large jigsaw puzzle that a warehouse can be when you have multiple vendors,” said Okabe.

SBR claimed that theirs is the first, and perhaps only, e-fulfillment facility in the world to automate pretty much everything that happens between receiving and shipping.

Ito noted that one important goal for the project “has been to have the robots do as much of the handling work as possible, while recognizing that there are some especially fragile items that should not be handled robotically.”

At present, more than 50% of the work in the facility has been automated, and about 60% of the items stored in the mini-load system can be handled by the robots. SBR continues to work with Berkshire Grey to increase that to 70%.

“There have been very few products that we have been unable to send to the robotic system cells,” Ito said.

Robot refinement ongoing

Going forward, the SBR team will continue to refine the system to handle more and more items robotically and to search for solutions to automate receiving and truckloading.

“Our vision is to be a world-class e-commerce fulfillment and automation integrator in the global market by 2030,” Ito said. “The introduction of robotics is a big first step for us to realize our vision.”

“We will continue to discover great solutions from around the world and combine them to solve the challenges of our customers in the logistics industry,” added Okabe.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up