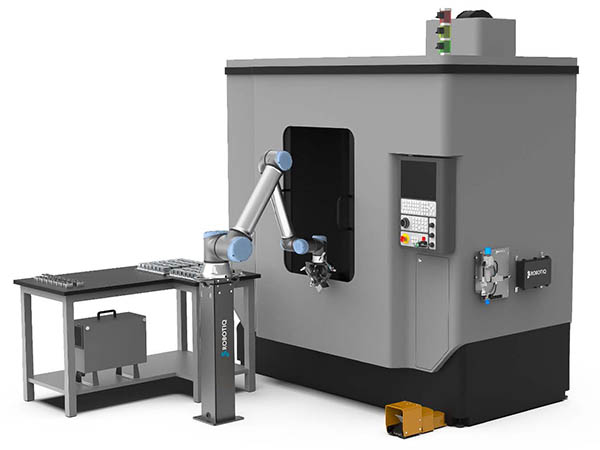

DETROIT—Manufacturers squeezed by supply chain challenges and labor shortages are considering automation, but they need to overcome accessibilty hurdles. To help them leap those hurdles, Robotiq today said at Automate 2022 here that its new Machine Tending Application Solution will make collaborative robots more accessible than ever.

The Lévis, Quebec-based company said its system can reduce implementation costs by up to 50% and takes less than two hours to go from unboxing to machining the first part—with no coding experience required.

“When a machine shop owner struggles to find employees to do the work, their first instinct is to look for new CNC machines that can run unattended for longer and with shorter changeover times,” said Samuel Bouchard, CEO of Robotiq. “But those machines are costly, and this, combined with a longer lead time, makes for a less-than-ideal solution.”

Robotiq simplifies CNC machine tending

Robotiq said its new technology emulates the machine operator, so there is no need to modify or alter the machine controls. Since it’s “non-intrusive,” the Machine Tending Solution will work with any brand of CNC machine, according to the company.

“Instead of hard-wiring the machine like with traditional automation, Robotiq’s Machine Tending Solution communication modules are non-invasive and do not require installation by certified technicians,” explained Bouchard. “The solution can be deployed in two to three hours, 75% faster than with traditional programming.”

Founded in 2008, Robotiq said its mission is to free human hands from repetitive tasks. The company claimed that it has freed more than 26,000 hands worldwide by providing easy-to-use cobot systems for tasks such as screwdriving to manufacturers of all kinds. Robotiq has more than 130 employees worldwide and said it can deliver a return on investment (ROI) in six to 18 months.

Cobot system can deliver peace of mind

Manufacturers using Robotiq's automation attest that it has simplified their lives and delivered peace of mind.

“This allowed us to stabilize production, delivery to customers, and productivity while solving our labor shortage challenge,” said Vincent Roussy, a manufacturing engineer at Usinatech Inc. His company, in Melbourne, Quebec, does high-precision machining for drive-train and transmission components such as gears and shafts.

“I never thought a robot would replace me, and I am happy to have my three robots,” said Hugo Santos, an operator at Usinatech. “My speed keeps increasing.”

“Running a job on a given machine with UR and Robotiq is four times cheaper than operating manually,” noted Ken Chess, chief operating officer at Fusion OEM.

Robotiq is showing its Machine Tending Application Solution at Booth 2438 at the Automate trade show in Detroit from June 6 to 9, 2022.

Article topics

Email Sign Up