The Association for Advancing Automation (A3) has published a white paper entitled “Robots Fuel the Next Wave of U.S. Productivity and Job Growth” in which data from the Bureau of Labor Statistics and a wide range of manufacturing firms document how and why increasing the use of robots is associated with increased employment.

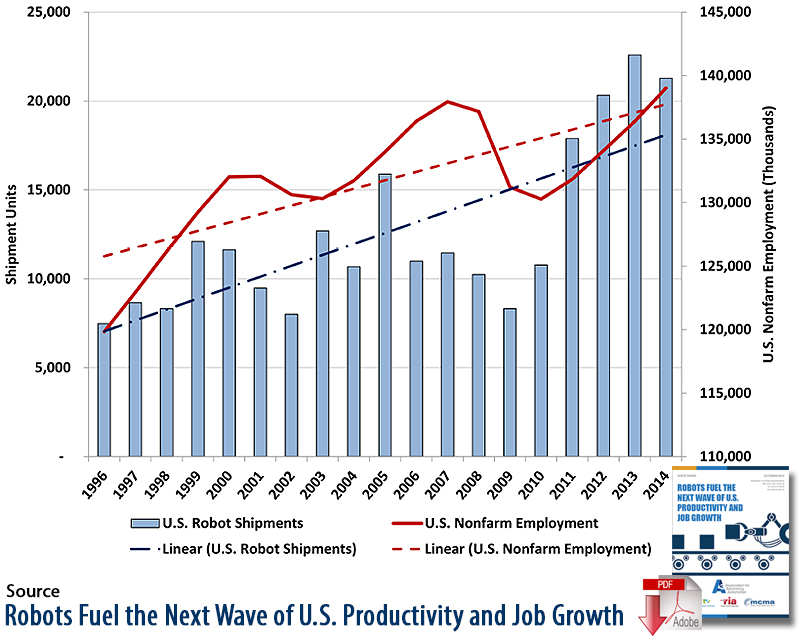

Key statistics from the A3 white paper show that during the non-recessionary periods - 1996-2000, 2002-2007, and 2010-2014 - general employment and robot shipments both increased.

Since 2010, the robotics industry in the United States has grown substantially.

Even during this period of record-breaking robot sales, U.S. employment increased.

This new data is in stark contrast to media coverage and a perception that increasing use of robots causes higher rates of unemployment in the U.S.

“We are seeing concrete shifts in the factors that resulted in cuts to the U.S. manufacturing work force over the past few decades,” said Jeff Burnstein, president of A3.

“Manufacturing automation increasingly provides the flexibility in the variety of tasks robots perform to drive improvements in overall product quality and time to market.”

U.S. Manufacturing Labor Productivity (Output/Hour) vs. Industrial Robot Shipments

(Bureau of Labor Statistics, 1987-‐2014)

Burnstein concluded, “One of the biggest challenges we now face is closing the skills gap to fill jobs. Robots are optimizing production more than ever, increasing global competitiveness, and performing dull, dirty and dangerous tasks that enable companies to create higher-skilled, better-paying, and safer jobs where people use their brains, not their brawn.”

As companies seek to bring manufacturing operations stateside while remaining cost-competitive, they continue to turn to automation to help lead the new wave of productivity and job growth in the U.S.

“The whole premise for our company is to bring manufacturing back to this country, and our new robot fits perfectly with that master plan,” said Geoff Escalette, CEO of faucet-maker RSS Manufacturing & Phylrich in Costa Mesa, California.

“Our robot not only makes it possible to increase production speed without buying additional CNC machines, but also helped us open up 30 percent more capacity on existing machinery.”

Robotics also helps companies stay competitive when seeking new talent - particularly those who are interested in long-lasting careers working with technology.

“It’s really an opportunity for us to grow,” reports Matt Tyler, president and CEO of Vickers Engineering, a contract precision engineering manufacturer in Michigan.

“Because we have robotics and are able to compete on a global scale, it makes the U.S. more competitive in manufacturing, and that’s good for all of us.”

Related: System Buyers Top 7 Most Important Characteristics of Material Handling Solution Providers

Article topics

Email Sign Up