A research team at Kansas State University 3D printed batteries using freeze casting and hybrid MoS2-graphene aerogels.

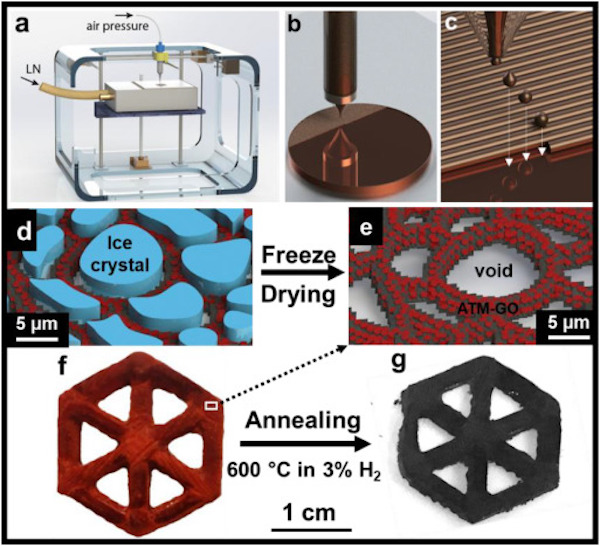

The process uses inkjet printing and freeze casting to control the microstructure and macroporosity of the structures during printing. Ink droplets (consisting of a molecular MoS2 precursor missed with graphene oxide nanosheets) are frozen during the 3D print process using a cold substrate plate set at -30° Celsius. The ice crystals formed when the droplets frozen form a matrix. The frozen droplets were used to form the aerogel, and undergo additional refinements and processes to create anodes for sodium ion batteries.

The resulting interconnected porous structures could mitigate the stress induced by larger volume changes during charge-discharge cycles of sodium ion batteries because of the higher specific capacity of the materials and larger ion size.

The researchers believe this is the first time that MoS2-rGO hybrid aerogels have been 3D printed.

The research, titled 3D printing of hybrid MoS2-graphene aerogels as highly porous electrode materials for sodium ion battery anodes,” appeared in Materials & Design.

According to the researchers, previous work using 3D printing to fabricate Li-ion battery electrodes have used materials with relatively low theoretical specific capacities.

Source: Materials & Design

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up