New Scale Robotics this week announced thread verification as the latest enhancement to its Q-Span Automated Gauging System. The robotic system is intended for for quality teams in high-mix, small-batch manufacturing.

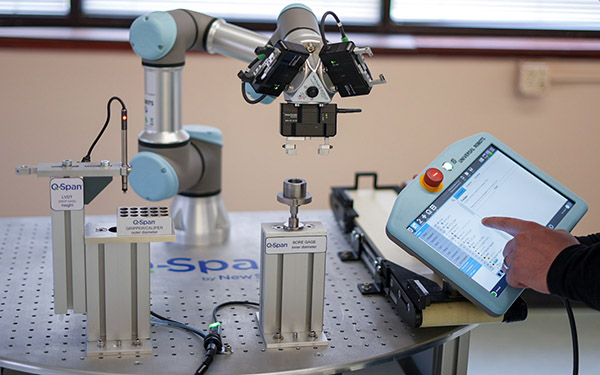

Victor, N.Y.-based New Scale Robotics said its Q-Span Workstations combine measurements from a wide variety of gauges with robotic part handling and automated data logging. The goal is to improve efficiency, capacity, and real-time reporting of quality departments, it said in a press release.

The Q-Span Workstations include flexible and teachable collaborative robots, and the do-it-yourself (DIY) automation can fit into existing workflows, said New Scale Robotics, a division of New Scale Technologies. The systems can help quality teams reduce errors, increase throughput, and better use skilled labor, claimed the company.

The robotic workstations are easy to deploy without specialized training, and they can deliver a return on investment (ROI) in less than 10 months, said New Scale Robotics.

How Q-Span works

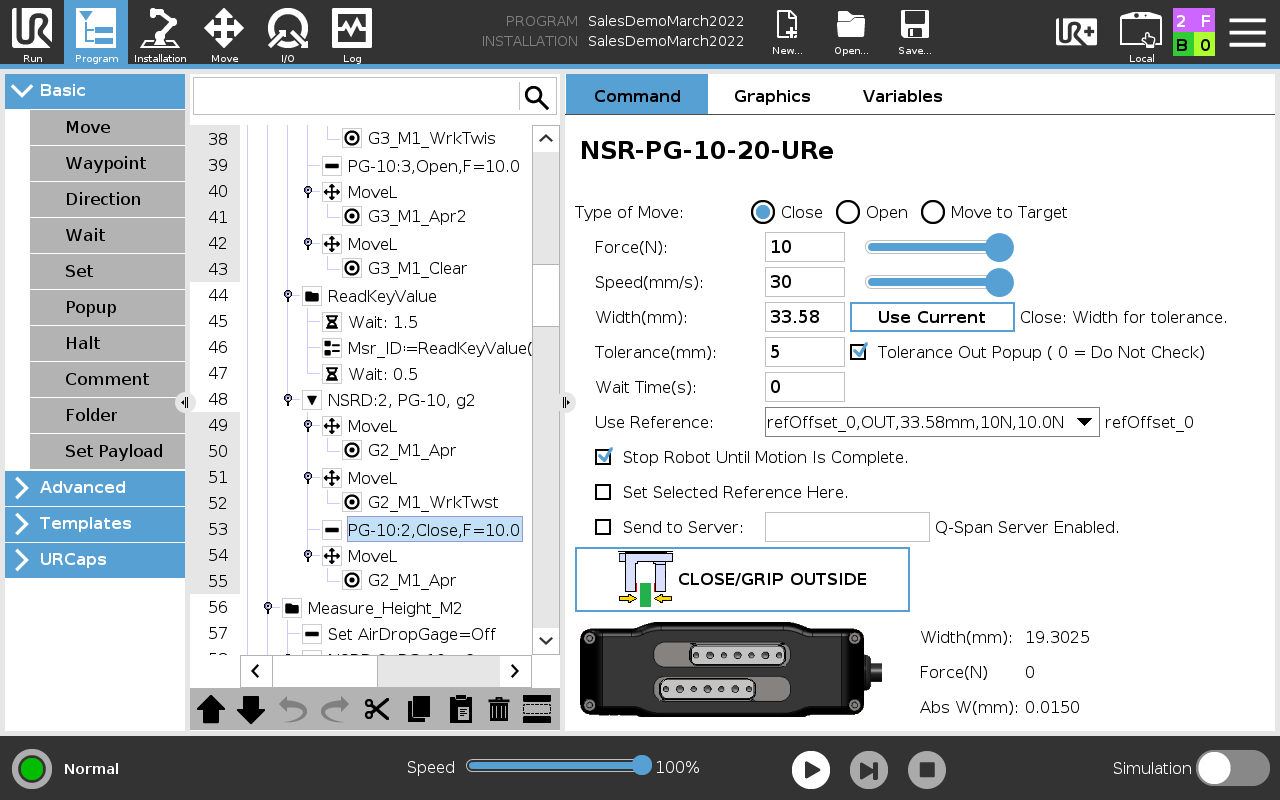

The Q-Span Gauging System combines existing manual gauges with a cobot, grippers for part handling, easy-to-use metrology and robot control software, and automated data collection.

A robot arm from Universal Robots loads parts into a fixture and activates the thread gauge to verify or chase threaded holes or external threads. The Q-Span System can then sort parts based on measured data, such as thread depth of blind holes, or it can reject parts for defects such as missing, short, or improperly formed threads.

Systems can be configured for “GO” gaging, “NO GO” gaging, combination gaging, or even thread chasing, said New Scale Robotics.

Data from all gauges in the Q-Span System – including thread gauges, robotic calipers, LVDT probes, drop gauges, bore gauges, laser micrometers, vision system, 2D telecentric profilers, and more – is combined into one convenient output for statistical process control (SPC), said New Scale. Data from any or all gauges can be used in real time for in-process decision making and process monitoring, the company explained.

New Scale Robotics to exhibit at PMTS

New Scale Robotics said it incorporates gauges and grippers to meet each customer’s initial needs, and users can easily configure the control software themselves for additional parts and processes. No robotics experience or special training is needed, the company added.

The Q-Span Gauging Systems with thread gauges are available now, said New Scale Robotics.

New Scale plans to show a Q-Span Automated Gauging System with a thread gauge, bore gauge, drop gauge, robotic calipers, and grippers for part handling in Booth 4109 at the Precision Machining Technology Show (PMTS) from April 18 to 20, 2023 in Cleveland.

Article topics

Email Sign Up