Piab AB recently announced its LBG-50 lightweight bag gripper. It said the new gripper can easily lift sacks and bags with weights of up to 50 kg (110.2 lb.). As a pre-engineered tool, it can also save valuable development time, claimed the company.

“LBG-50 is the result of our long experience from developing custom palletizing end-of-arm tooling (EOAT),” stated Madeleine Sheikh, product manager at the Piab Vacuum Automation Division, in a release.

“What we have here is a complete pre-engineered bag gripper that is easy to install, adjust and maintain,” she added. “It offers flexibility to fit any roller conveyor on the market, and slip sheets are handled just as easy by our vacuum-based upgrade option with Duraflex suction cups and COAX technology.”

Piab Group has sold gripping, lifting, and moving systems since 1951. The Täby, Sweden-based company said automation can eliminate resource waste and worker injuries. It has reported annual sales of about $175 million (U.S.).

Piab said it has more than 650 employees and a presence in more than 100 countries with a network of subsidiaries and channel partners. Patricia Industries, part of Investor AB, has owned Piab since 2018. Its U.S. office is in Hingham, Mass.

Piab assesses bag-handling challenge

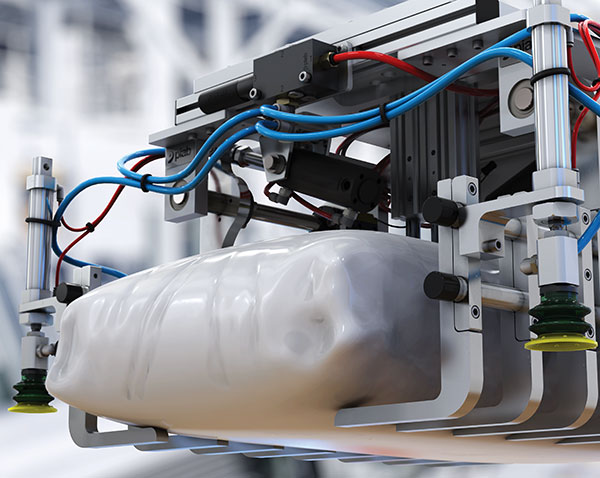

“Handling sacks normally poses a challenge, as they are heavy and flexible, yet with a surface that is sensitive to pinching, puncture, or rough treatment,” said Piab.

Getting the exact measurements of bags to align with conveyor rollers for a smooth lifting and releasing process is a challenge when defining a new bag-gripping system, the company noted. This requires time for analysis, adaptation, and adjustments, it said.

In addition, robotics developers, integrators, and end users may have to consider other systems for tasks such as slip sheet handling. This can further prolong the implementation process and can even interfere with the original intent and setup of a robotic gripper, according to Piab.

LBG-50 designed to solve palletizing problem

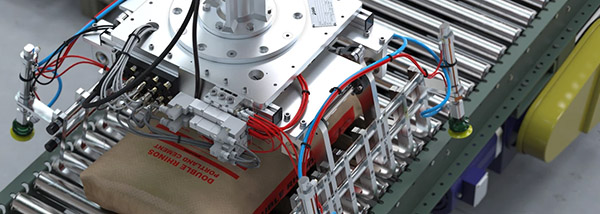

Piab said its latest palletizing tool, the LBG-50 solves bag-handling problems. The system provides a gentle but firm lift, while a built-in top clamp plate secures the bag from above during motion, it explained. This, in turn, allows higher cycle speed, said the company.

In addition, Piab said it makes the arm and the framework of LBG-50 out of aluminium to make it robust yet lightweight. Its features include flexible width and finger positioning, as well as a variety s mounting options.

The gripper is also designed for flexibility, including its valve package, which can be configured with either Discrete I/O, Ethernet/IP or Profinet.

“LBG-50 will be built-to-order in both the EU and the U.S,” said Sheikh. “We recommend consulting an application engineer to ensure the correct gripper selection before purchase.”

Article topics

Email Sign Up