Depalletization is a popular application for robotics, and artificial intelligence and machine vision are enabling greater precision. Photoneo today introduced its AI-based Depalletization and Delayering tools for automated pallet unloading. The Bratislava, Slovakia-based company said they can increase efficiency, reliability, and safety, as well as order-fulfillment accuracy for logistics businesses.

“We trained the AI algorithms on huge datasets of images to provide customers with a robust and reliable solution for any type of fully automated pallet unloading,” stated Marcel Svec, vice president of strategy and products at Photoneo.

“The algorithms can recognize any type of items and boxes, including different sizes, irregular shapes caused by damage, or problematic surfaces such as varying textures, shiny and reflecting materials, black color, protruding tapes, patterns, or pictures that tend to mislead standard 2D vision, but not our 3D vision,” he said.

Founded in 2013, Photoneo has developed what it claimed is “the world’s highest-resolution and highest-accuracy color 3D camera.” The company has also developed machine learning software to help the automotive, logistics, e-commerce, grocery, and medical industries to improve the performance and efficiency of manufacturing, assembly, fulfillment, and other processes.

Depalletization and Delayering get smarter

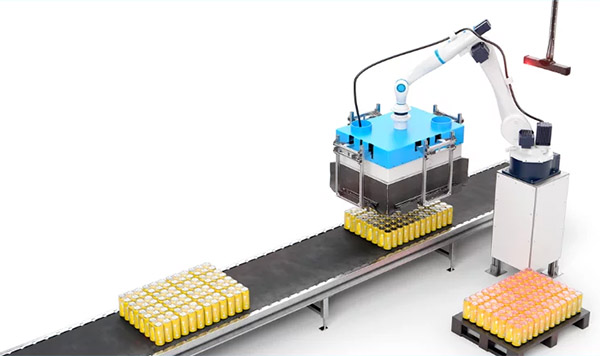

“Depalletization and delayering refer to the process of unpacking or breaking down larger units, such as pallets or layers, into smaller units for further distribution or handling,” wrote Andrea Puflerova, public relations specialist at Photoneo, in a blog post. “Both depalletization and delayering play crucial roles in optimizing the flow of goods in logistics, particularly in warehouses, distribution centers, and factory floors.”

Photoneo said its Depalletization and Delayering tools come as extension modules to its existing 3D picking systems, Bin Picking Studio and Locator Studio. Each targets targeting a different process of automated pallet unloading:

- Depalletization is for robotic unloading of individual boxes.

- Delayering focuses on robotic unloading of entire layers of goods.

These two tools offer unique flexibility and high modularity, claimed the company. They are powered by robust neural networks that were trained on thousands of items to be able to recognize boxes and goods of various shapes, sizes, colors, materials, and textures, said Photoneo.

“The [Depalletization] algorithms can also easily recognize boxes that are very tightly packed,” said Pufflerova. “This is often a big challenge for automation systems, as it is difficult for them to differentiate the line separating two boxes from a line contouring the opening of one particular box.”

“The modular nature of Depalletization allows you to use the tool as a stand-alone vision solution or to upgrade it with path planning to be used in vision-guided robotics,” she added.

The Delayering module enables robots to take the entire top layer of a load from a pallet, regardless of its shape and size, said Photoneo.

“Because it is so flexible, the solution works with any type of goods, including bottles, paper rolls—stand-alone or packed in plastic bags—and even mixed types of goods or exceptionally challenging materials such as plastic bags,” wrote Pufflerova.

Photoneo provides for easy integration

As extensions to existing software, Depalletization and Delayering are easy to deploy for existing users, asserted Photoneo. The modules are customizable, so companies can adjust their performance to their specific application needs, it said.

In addition, both functionalities are compatible with many robotic brands, grippers, and environments, said Photoneo.

When customers purchase a new Locator Studio or Bin Picking Studio, Photoneo said it will provide them with a vision controller with pre-installed software.

Article topics

Email Sign Up