Nanyang Technological University, Singapore (NTU Singapore), HP and the National Research Foundation Singapore (NRF) launched the new HP-NTU Digital Manufacturing Corporate Lab.

As Singapore’s newest corporate research laboratory and HP’s largest university research collaboration worldwide, the HP-NTU Corporate Lab will drive innovation, technology, skills and economic development critical for the advancement of the Fourth Industrial Revolution. This is HP’s first university laboratory collaboration in Asia.

The $84 million lab supports Singapore’s push toward industry transformation—in the areas of digital manufacturing and 3D printing technologies. Advanced Manufacturing and Engineering is one of four technology domains under the Research, Innovation and Enterprise (RIE) 2020 Plan, which is Singapore’s national strategy to develop a knowledge-based innovation-driven economy and society.

Located at NTU, the HP-NTU Digital Manufacturing Corporate Lab was launched by Heng Swee Keat, minister for Finance and chairman of the NRF. The NRF facilitates the setting up of corporate labs via public-private partnerships. The Corporate Lab is the 13th supported by NRF and the seventh such lab at NTU.

The lab’s 100 researchers and staff will focus on digital manufacturing technologies, specifically in areas of advancing 3D printing, artificial intelligence, machine learning, new materials and applications, cybersecurity and customization.

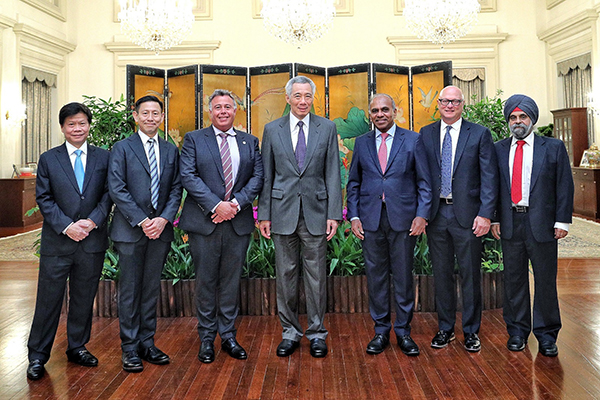

The partnership was inked by NTU Vice President (Research) Professor Lam Khin Yong and HP Chief Technology Officer and Head of HP Labs Shane Wall. It was witnessed by Guest-of-Honour Minister for Finance and NRF Chairman Heng Swee Keat, NTU President Professor Subra Suresh and HP Inc. Chief Executive Officer and President Dion Weisler.

(Clockwise from bottom right) NTU Vice President (Research) Prof Lam Khin Yong and HP CTO Shane Wall signing the corporate lab partnership agreement, witnessed by HP CEO Mr Dion Weisler; Minister for Finance and Chairman of the NRF Mr Heng Swee Keat; NTU President Prof Subra Suresh, and NRF CEO Prof Low Teck Seng. Image courtesy of NTU Singapore.

(Clockwise from bottom right) NTU Vice President (Research) Prof Lam Khin Yong and HP CTO Shane Wall signing the corporate lab partnership agreement, witnessed by HP CEO Mr Dion Weisler; Minister for Finance and Chairman of the NRF Mr Heng Swee Keat; NTU President Prof Subra Suresh, and NRF CEO Prof Low Teck Seng. Image courtesy of NTU Singapore.“Corporate laboratories are an integral part of our strategy to anchor joint R&D partnerships between our universities and companies in areas that have direct relevance to the growth of industries in Singapore,” NRF CEO Professor Low Teck Seng says. “The HP-NTU Digital Manufacturing Corporate Laboratory is significant to our long-term competitiveness in the advanced manufacturing sector, and ensures that we stay relevant in the Fourth Industrial Revolution that is evolving and growing rapidly world-wide. It will also strengthen our capabilities to support multinational companies for expansion from Singapore into the region.”

NTU President Professor Subra Suresh said the partnership with HP is a significant milestone for NTU, as 3D printing—along with adjacent technologies such as artificial intelligence (AI), machine learning and cybersecurity—are integral parts of the Fourth Industrial Revolution.

“NTU has established deep capabilities and is a recognized leader in the areas of machine learning, data science and additive manufacturing. These cutting-edge technologies are now an integral part of NTU’s education and research ecosystem, and the NTU Smart Campus serves as a test bed for them. This is aligned with Singapore’s vision of transforming into a Smart Nation,” Suresh says.

“The World Economic Forum estimates more than $100 trillion in value will be created by digital transformation across all industries in the next 10 years,” says Dion Weisler, CEO and president, HP Inc. “HP is helping lead the development of the underlying technologies, like 3D printing, that will enable the benefits of this transformation. Singapore is one of our key worldwide technology development and manufacturing centres in print technology. The HP-NTU Digital Manufacturing Corporate Lab will significantly deepen our involvement here and serve as a nucleus for this ecosystem.”

The new Corporate Lab will be a key pillar of NTU’s Smart Campus initiative and will build on HP’s strong research and manufacturing capabilities.

At launch, the lab will prioritize 15 projects to better understand:

- new materials and applications: such as advanced polymers for manufacturing applications, the development of bioprinting models toward printing viable tissues, and 4D printed smart systems that adapt shape with temperature change;

- artificial intelligence and machine learning: helping printers autonomously predict and resolve issues; and

- cybersecurity: research to improve end-to-end point security infrastructure and malware mitigation.

The collaboration will also include developing educational curriculum on designing for additive manufacturing—covering areas such as data management, security, user experience and business models.

Sources: Press materials received from the company.

About the Author

Press releases may be sent to them via [email protected]. Follow Robotics 24/7 on Facebook

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up