While robots are changing materials handling, they have operational constraints because of safety requirements. NEC Corp. last week said it has developed a control technology that doubles the efficiency of autonomous mobile robots, or AMRs, in warehouses while maintaining a high level of safety. The Tokyo-based company plans to put the technology into practical use by March 2024 and to install it in NEC's collaborative AMRs in Japan.

In the past few years, the adoption of robots by large warehouses and distribution centers has accelerated because of labor shortages and the growth of e-commerce. However, there are challenges to introducing AMRs into existing warehouses to improve efficiency.

AMRs must move at low speeds to ensure safety, and operators often build passageways and areas dedicated to mobile robots so they can accelerate, noted NEC.

NEC develops novel control technology

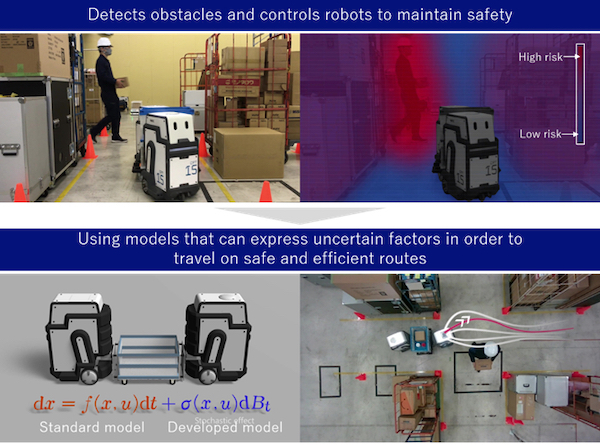

NEC said it has developed “risk-sensitive stochastic control technology” so that AMRs can move at higher speeds and still meet safety requirements. It uses models that can express uncertain factors that vary from one site to another, such as sensor measurement errors and differences between simulation results and actual robot movements.

In addition, this new technology has adopted methods that have been used in actuarial finance, the company explained.

Robots could use this control technology to autonomously determine when to travel at high speed and over the shortest distances, such as when traveling in low-risk locations without workers, objects on the floor, or other obstacles.

Conversely, robots will travel at a low speed when using routes that are determined to be high-risk locations. When comparing transport work between a robot applying the stochastic control technology and a conventional robot, NEC confirmed that the work time was halved and the transfer efficiency could be doubled while ensuring safety.

In addition, safety and efficiency can be achieved without dedicated robot lanes, making it easier to install AMRs in existing facilties without infrastructure or layout changes, claimed the company.

NEC, whose stated goal is “orchestrating a broader world,” plans to contine developing this adaptive control system. The company added that it plans to conduct on-site demonstration experiments, aiming for early installation in mobile robots for a wide range of industries.

Article topics

Email Sign Up