As part of its redesign, MSC Industrial Supply transitioned from a traditional pick-and-pass approach order fulfillment system to a more streamlined solution.

Now, the different pieces of a multi-line order are picked simultaneously and conveyed to a consolidation area where they are married together.

The result is a highly efficient process that has dramatically reduced cycle times.

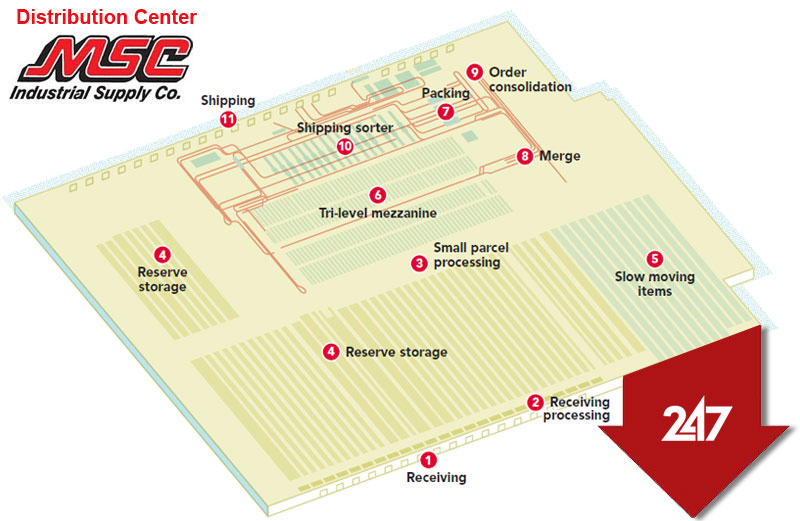

Receiving: MSC receives (1) several different types of shipments, including small parcel, less-than-truckload and truckload shipments, and ocean containers. Floor loaded cartons are palletized and then moved with lift trucks to a receiving processing area (2).

There, the contents are verified against a purchase order. Small parcel shipments are processed in a separate area (3). Once the material has been verified and entered into the warehouse management system (WMS), it is ready to be put away into storage.

Storage: Newly arrived product is putaway into storage in the reserve storage area (4), the slow moving items area (5) and the tri-level mezzanine (6). Product destined for the mezzanine and slow moving area is put away after hours so as not to interfere with order fulfillment processes.

Cartons travel by conveyor from the receiving area to a sortation area. There, associates build pallets and carts with product that will be stored in those areas. In the slow moving SKU area (5), product is stored by associates on man-up lift trucks. The associate scans the bar code label on a carton and on a storage location to confirm the put-away in the WMS.

In the mezzanine area (6), cartons are placed on carts that are transported to the right level for storage. Associates follow the same process to confirm the putaway in reserve storage (4).

Picking: The picking process is initiated when orders drop from the order management system into an order queue in the WMS. At that point, an associate referred to as a wave master prioritizes the orders based on a variety of criteria. That may include what time of day the order has to ship, whether it’s a hot order or whether the wave master wants to balance the work load in certain areas of the distribution center.

Orders are entered into a wave planning software application. Once a wave has been built, picking tasks are distributed electronically to the order selectors’ RF guns, known as merchandise selectors. The system is designed to pick all line items in an order individually and simultaneously and then to marry those items up in a centralized consolidation area.

Slow moving SKUs: In the slow moving SKU area (5), merchandise selectors work from man-up lift trucks. Once a merchandise selector arrives at a picking location, he scans a location bar code label and then scans a label on the item. That will generate a shipping label that is applied to the item or to a package if the item is placed in separate packaging for shipping.

The item is then scanned into a tote. Once the picks in that area are complete, the tote is placed on a takeaway conveyor and the warehouse control system routes it to the next stop. Single line orders are conveyed directly to the packing area (7). If the tote is part of a multi-line order, it is conveyed to the consolidation area (9).

Tri-level mezzanine: Merchandise selectors perform similar steps in the tri-level mezzanine (6): after scanning location and item bar code labels, the system generates a new pick label for shipping.

The item is then scanned into a tote that is placed on a takeaway conveyor and merge (8) in the mezzanine. The tote is then conveyed to the packing area (7) or to the order consolidation area (9).

Order consolidation: Totes with single line orders are conveyed directly to the packing area (7). Multi-line orders, however, must be consolidated before they are sent to packing. Totes arriving from the various picking areas are merged onto one conveyor line at a saw-tooth merge (8).

From there, totes are sorted into a two-level consolidation deck (9). Each level has 128 accumulation lanes; each lane can hold up to seven totes, representing seven lines arriving from seven different areas of the building. A light at the end of the merge alerts an associate when all of the items for a single order have arrived and are ready for the next step in the process.

Since several orders may be ready at the same time, a blinking light alerts the associate to the order that must be completed first. The associate marries the items for an order into just one tote. Once all of the items for that order are in a tote, it is conveyed to the packing station (7).

Packing: Both single-line and multi-line order totes ultimately arrive at the packing station (7). There, a packer verifies that all of the items required for the order are present. The packer then places the items in an open top shipping carton for that order.

Next, an automated packaging system adds the packing slip and printed marketing materials, adds protective transport packaging such as air pillows, seals the lid on the carton, and diverts it to the right shipping lane (10), depending on the carrier.

Put-to-light order consolidation and packing: Some orders may require more than seven line items or may call for large items that won’t fit into one tote. Those totes are conveyed to a put-to-light carton flow rack with workstations on either side of the rack.

The put-to-light area is located under the packing area (7). When a tote arrives on one side of the rack, an associate scans a bar code label on the tote. Lights on the carton flow rack tell the associate where to place the tote.

Once all of the totes for an order are in the carton flow rack, a light on the other side alerts a packer that the order is ready to be finished. The packer places the items in an open top shipping carton and it is conveyed to the automated packaging area (7) where it goes through the same process mentioned above in packaging.

Shipping: Cartons that can be live loaded are conveyed (10) directly into a trailer. Other cartons are conveyed to a palletizing station where pallets are built for shipping and then loaded onto a trailer.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up