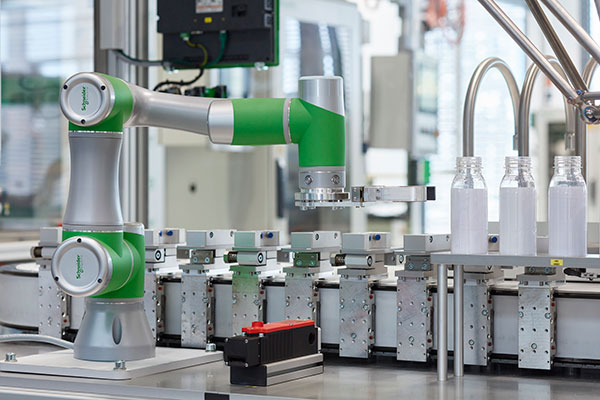

Schneider Electric announced the release of two new Lexium cobots at MODEX 2024. The company announced the Lexium RL 3 and RL 12, as well as the Lexium RL 18 model, scheduled to come later in 2024.

From single-axis machines to high-performance multi-axis machines, the comprehensive Lexium cobot line enables high-speed motion and control of up to 130 axes from one processor for precise positioning to help solve manufacturer production, flexibility and sustainability challenges.

Schneider Electric offerings encompass robotics suite

Schneider Electric goes beyond robots to provide fully integrated automation systems - digitally designed from concept to operation and maintenance. The company integrates robots into the machine control system through the EcoStruxure architecture, which enables collaborative data flow from shop-floor to top-floor, by connecting smart products, robots, controls, software and services.

Controlled by Modicon motion controllers, the system unifies PLC, motion and robotics control functionality on a single hardware platform and integrates into EcoStruxure Machine Expert software.

“As US manufacturing increases, the demand for smart machines is growing and customers are requiring robots with digital twin capabilities that validate machine performance to help them quicky increase production consistently, efficiently, and sustainably,” said Christine Bush, Robotics Center of Excellence leader at Schneider Electric. “We are partnering with our customers to understand their challenges and pain points, then responding with complete, customized automation solutions - from power products and HMIs to PLCs and robotics - to simplify the process and meet their needs.”

Compatibility with EcoStruxure Machine Expert Twin, a digital twin software suite that creates digital models of real machines, allows for virtual test strategies and commissioning, as well as shortened factory acceptance testing. Digitizing these processes can reduce time-to-market by up to 50% and commissioning time by up to 60%, according to the company.

Lexium cobot enhancements

Lexium cobots are part of a full line of robotics and automation options developed to meet manufacturer needs across industries, including warehouse/logistics, life sciences consumer packaged goods and more. According to Schneider Electric, some potential benefits of the Lexium cobot line and other motion offerings from the company include:

- Fast deployment: Built on open automation standards and protocols, cobots offer flexibility, scalability and third-party equipment integration. They can be applied to existing or new production lines in a variety of different industries.

- Streamlined integration: Enhanced computing power, open software and networking technologies facilitate quicker assembly, installation and robotic maintenance. A centralized architecture with a unified programming platform using open standards promotes interoperability among automation systems, machines and robots.

- Consistent output: Designed to handle repetitive tasks without errors or distractions, cobots can maintain Overall Equipment Effectiveness while manufacturing higher volumes of quality goods over shorter periods 24/7 without fatigue. This produces a consistent output with little variability over a given production batch.

- Workplace health and safety: Cobots perform well in harsh environments and can handle riskier operator tasks involving heavy weights to reduce accidents and injuries.

Amidst the rapid growth of US manufacturing, companies are increasingly seeking digital, efficient, and sustainable options to meet expanding output demands.

Want to learn more about cobot arms? This article was featured in the April 2024 Robotics 24/7 Special Focus Issue titled “Collaborating with robot arms, platforms.”

Article topics

Email Sign Up