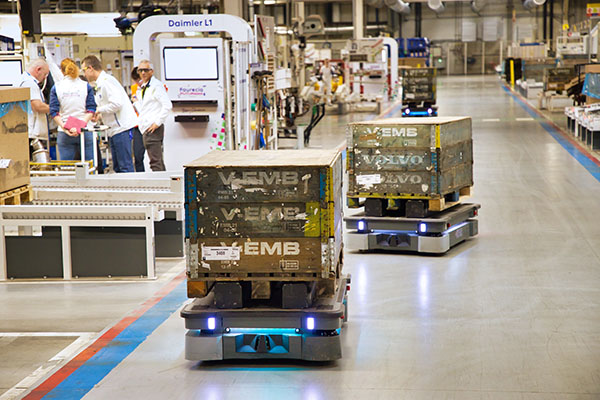

The idea of fully autonomous mobile robots, or AMRs, interacting seamlessly with human employees in warehouses and factories seemed like a futuristic vision just a decade ago, according to Mobile Industrial Robots ApS. Today, thousands of AMRs deliver parts, transport finished products, and handle other logistics tasks without the need for human operators, separate work areas, or external guidance, said the Odense, Denmark-based company.

Analysts have predicted that the market will experience double-digit growth every year through at least 2027.

“MiR was one of the early movers in the AMR industry and was visionary in developing a scalable platform of robots that could be easily deployed and integrated into factories and warehouses,” said Ash Sharma, managing director at Interact Analysis. “It continues to innovate and has helped the industry to grow from a fledgling industry to what is now a multi-billion-dollar sector with AMRs deployed in thousands of buildings around the world.”

Jean-Pierre Hathout, president of Mobile Industrial Robots (MiR), said in a press release that customers are now transitioning from using AMRs in pilots to using them 24/7 in production applications, with MiR leading that transition.

“In the first 10 years of MiR’s history, we led the industry with innovative AMRs as we scaled globally with our customers,” he stated. “I couldn’t be more excited about the next 10 years as we build on that innovation to provide a full range of AMR solutions on common software for our global customers.”

MiR founded with global ambitions

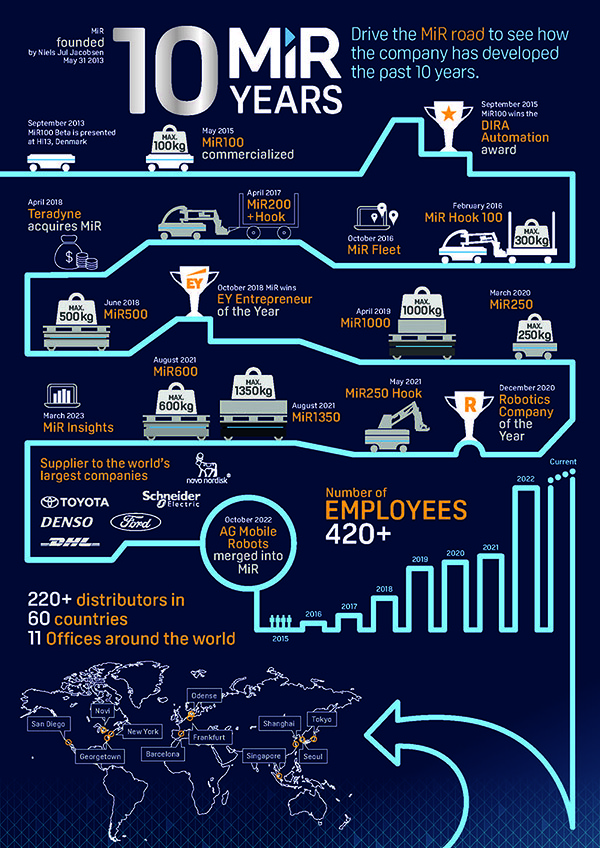

Niels Jul Jacobsen founded Mobile Industrial robots in 2013 to change how companies handle their internal logistics. Thomas Visti joined him in late 2014. Both had experience from another successful robotics company, collaborative robot maker Universal Robots A/S, providing them with valuable market insights and a strategy for taking the company from scratch to a world leader in only a few years, claimed MiR.

In the early years, Visti took to the road with a MiR100 robot in the back of his car, giving demonstrations to distribution partners and prospective customers. From the very beginning, MiR said it focused on a global market approach based on sales and service via distributors and a focused product range.

Today, more than 220 distributors and certified system integrators in 60 countries sell MiR robots. The company has regional offices in Boston; Holbrook, N.Y.; San Diego; Chelmsford, Mass.; and Georgetown, Ky. It also has offices in Singapore; Frankfurt, Germany; Barcelona, Spain; Yokohama, Japan; Seoul, South Korea; and Shanghai.

Mobile Industrial Robots on steady growth trajectory

In April 2018, North Reading, Mass.-based Teradyne Inc. acquired Mobile Industrial Robots, adding it to its portfolio alongside Universal Robots. From just three employees at the start of 2015, MiR currently employs more than 420 people globally, with an annual turnover of $77 million (U.S.) in 2022.

MiR said large multinationals, including Toyota, Ikea, Novo Nordisk, Denso, DHL, and Schneider Electric, account for a majority of its sales.

Last year, Teradyne merged Mobile Industrial Robots with AutoGuide Mobile Robots. This added high-payload AMRs to MiR's portfolio, advancing its strategy of being a trusted supplier for a full range of AMRs to global customers.

“MiR has the proven products, the experience and support structure to help our customers scale; and as a part of Teradyne, we are a trusted long-term supplier for mission-critical production applications,” added Hathout.

Strategy focuses on software development

In addition to continuously developing new AMR models, Mobile Industrial Robots recently launched MiR Insights, a cloud-based software tool that enables fleet owners to manage and optimize the operations of its robots. They can gain actionable insights to improve the robots’ deployment, it said.

“As robot fleets grow, so does the demand for software tools to optimize performance and manage full fleets,” Hathout said. “If we want AMRs to be as common as forklifts and pallet lifters, it is essential that we lower the barriers for implementation, reprogramming, and maintenance. We have already made substantial progress in this direction, and I firmly believe we have only glimpsed the true potential of automated logistic solutions.”

Article topics

Email Sign Up