Kassow Robots ApS, which has developed seven-axis collaborative robot arms, yesterday said it plans to exhibit at the Automate event for the first time. The Kastrup, Denmark-based company said its cobots are designed to be easy to use for multiple applications.

“The cobots are perfect for limited-space retrofits and applications such as machine tending, pick-and-place tasks, quality inspection, and palletizing,” said Kassow. “No in-depth programming knowledge is required to operate the cobots, allowing small and medium-sized enterprises (SMEs) without robotics specialists to implement automation and programming cost-effectively and independently.”

Founded in 2018, Kassow said it designs and manufactures lightweight industrial robots for “strong, fast, simple” tasks. The company claimed that its line of five seven-axis robots “offers a unique package of speed, power, and reach.”

Bosch Rexroth became majority owner of Kassow Robots in April. Founder Kristian Kassow is now co-owner and continues to serve as CEO of Kassow Robots. The company recently partnered with distributor Rehm Kft. in Hungary.

KR series designed for flexibility

Kassow said its line of five KR series cobots offer speed and power combined with a long reach and a high degree of flexibility to work in tight and awkward spaces.

They can handle payloads up to 18 kg (39.6 lb.) and reach up to 1,800 mm (70.8 in.), allowing customers to automate a variety of physically demanding and/or repetitive tasks, said the company.

In addition, the collaborative robots' seventh axis enables continuous dispensing, packaging, welding, bin picking, and material removal, regardless of access angle, without the need to reorient the arm, according to Kassow.

When combined with simple programming techniques, the company said its cobots can help customers and integrators quickly and cost-efficiently automate complex tasks in material handling and other industrial applications.

Kassow to debut at Automate

Kassow Robots will be exhibiting its flexible cobots at Booth 1452 at Automate 2022 in Detroit from June 6 to 9.

The Association for Advancing Automation (A3), which organizes the event, described it as “the largest solutions-based showcase of automation, robotics, vision, motion control, and more in North America.”

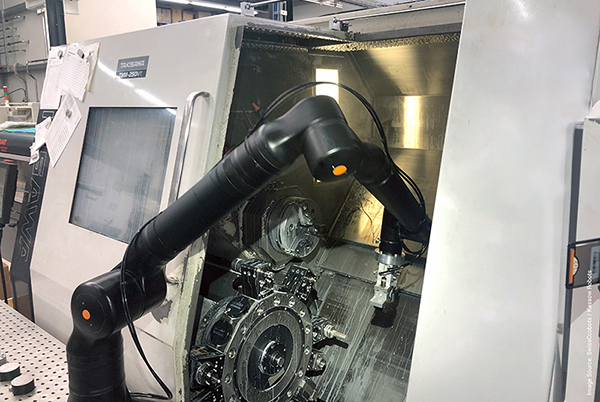

Kassow said its KR1805, its newest model, enabled Jules Bertschinger's machine shop floor to insert and remove workpieces from a CNC lathe machine. The company said its ability to replicate the movement of a human arm and operate in tight spaces enabled it to assist the company's production operation.

Article topics

Email Sign Up