Like many other small and midsize enterprises, HWL Löttechnik GmbH has faced growing labor shortages, demands for energy efficiency, and the intricacies of high-mix, low-volume production. The thermal treatment company has deployed a robot using the MIRAI intelligent vision technology in its Berlin factory to take over the repetitive task of handling reflective metal objects.

HWL has customers in power plant engineering, automotive, electronics, aerospace, and tool industries, as well as plant and fixture construction. The family-run company said it has invested in state-of-the-art technolgies to optimize operational processes and position itself as an attractive employer.

The metal parts HWL needed to handle varied in size, position, and appearance, and the lighting conditions in its facilities could also change. It turned to Micropsi Industries' MIRAI controller, which is designed to use artificial intelligence to make programming robots faster and easier.

Micropsi, which is also based in Berlin, provides software for industrial and collaborative robots. The company claimed that MIRAI allows robot arms to be controlled in real time in direct response to sensor data.

Handling process requires flexible systems

HWL said its commitment to the highest quality standards and continuous innovation goes hand in hand with prioritizing employees' expertise and satisfaction. Kai Lembke, CEO of HWL, recognized that thermal treatment was physically demanding and repetitive work and that labor shortages had led to increased workloads for existing staffers.

In response, he set out to identify the task that could benefit the most from automation. With his dedicated team, Lembke identified a prime candidate: the loading of metal parts onto racks from washing baskets.

Before heat treatment, the serial parts undergo a meticulous cleaning process in a cabin-washing facility, said HWL. Each customer typically delivers around 900 to 1,000 parts in large loading carriers, which employees manually transfer into washing baskets.

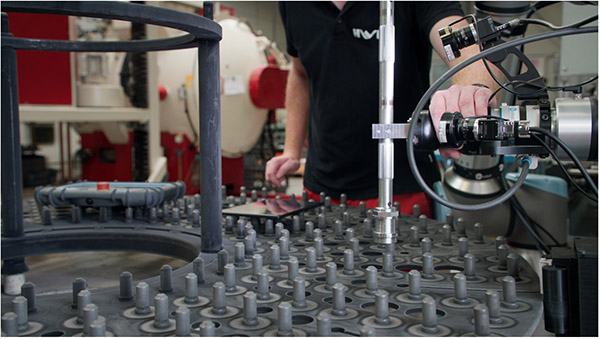

The parts in the baskets are then carefully placed onto multi-tiered racks using a peg system before being transported to the oven for heat treatment.

The immense diversity in size and weight of the metal parts, combined with their fragile nature prior to heat treatment, made the handling process extremely complex, noted Lembke. He said the following factors made automation with conventional systems impossible:

- Variance in the size and weight of the components

- Variance in the positioning of the components within the washing basket

- Variance in the position of the racks

- Variance in the appearance of the component due to reflection and changing lighting conditions

MIRAI frees up employees and ensures competitiveness

In October 2022, a collaborative robot equipped with MIRAI took over the task of loading the parts. After the washing process is completed, the AI-powered system takes control of the cobot.

Guided by MIRAI, it individually lifts the delicate parts from the washing baskets and places them on the pegs in the racks. The vision system automatically adapts to the sizes and weights of these highly individualized parts, explained Micropsi.

Unlike traditional vision systems, even changing lighting conditions and resulting reflections on the surface of the workpieces do not affect the functionality and precision of the system, it asserted.

“By automating processes with MIRAI, we can save costs and position ourselves as an innovative and modern company while enhancing the attractiveness of our workplace,” Lembke said.

Since implementing MIRAI, HWL reported that its employees have taken on the responsibility of managing and retraining the system, which is especially important when faced with changing requirements or environmental modifications.

“The fact that these adjustments can be made by our employees without the need for experienced programmers from the manufacturer is a significant advantage,” said Lembke. “We have even been able to optimize cycle times by 20%. That's exactly the flexibility we need.”

“By automating processes, we can save costs, position ourselves as a progressive and modern company, and enhance the attractiveness of our workplace,” he said.

As a result of these positive experiences, HWL envisions adding more AI-based applications soon, said Lembke.

Article topics

Email Sign Up