Home Depot’s supply chain swings into action in response to the following simple question presented to online shoppers: Would you like to pick that up at the store or have it shipped somewhere?

Depending on the answer, the company’s 70 distribution centers, 18 rapid deployment centers, three new direct fulfillment centers (DFC) and legacy buildings will direct product to the customer’s chosen destination on their schedule, whether it’s the next day (when possible) or next month per the customer’s request.

The concept of the DFC is the latest addition to the company’s network. Consisting of three new regional locations working in tandem with legacy buildings to serve the entire country, the facilities are focused on filling orders placed online. While a relatively small part of the business, e-commerce volume could quadruple in coming years, so the DFCs have been designed for flexibility. Inside the company’s new DFCs, conveyable and non-conveyable items are processed with a mix of light automation and an assortment of picking techniques that enable real-time response.

Network size: More than 70 DCs in the U.S., including 18 rapid deployment centers and three new direct fulfillment centers (DFCs)

Stores serviced: 1,977 stores in the U.S.

Locust Grove facility size: 1.1 million square feet

Products: Home improvement and restoration materials

SKUs: 25,000, with a potential of 50,000 to 100,000

Staff: Two shifts, seven days, with more than 300 associates working multiple staggered shifts

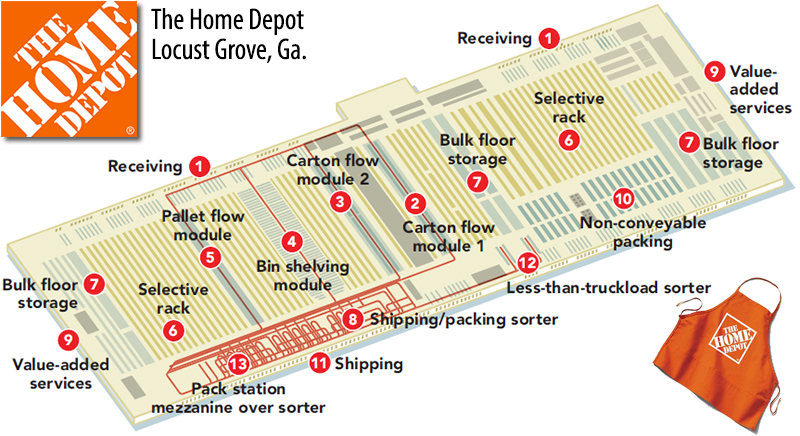

Receiving: Inbound trailers are identified as either imported or domestic inventory. The yard management system (YMS) routes the trailers to the appropriate half of the dock for receiving (1) or to the yard.

Incoming loads are either single-SKU or multiple-SKU pallets. Full pallets receive internal labels and are taken off to pick locations (2, 3, 4, 5) or selective rack (6) in reserve storage. Mixed-SKU pallets are depalletized onto carts. The carts resemble Gaylords with collapsible shelves on each of three sides. The carts can receive and stack in a denser capacity than on a pallet, and their contents are primarily directed to forward pick areas before any remainders are palletized in reserve storage.

Putaway/replenishment: Putaway is done with carts and pallets. An associate scans the label on each pallet, or the cart’s license plate, and is given a task and drop area. Most carts are received directly to carton flow pick modules (2, 3) or bins (4), where the associate scans product into each location. Replenishment personnel also take carts into reserve storage (6).

Well-cubed but larger items, like bathtubs, can only be stacked two or three high, so are stored in racks. But large items that can stack 14 to 16 feet high are stored in a bulk area (7). The bulk areas also house pick locations.

Order fulfillment: Orders are allowed to pool overnight, and when a wave drops, the first step is the creation of replenishment tasks based on those waves. Pickers begin their work 30 to 60 minutes after that, and packers follow shortly afterward. There are several picking processes, depending on the order profile and where the items are stored in the facility.

Picking conveyables and non-conveyables: Every type of pick module has reserve locations. Fast movers are kept in pallet flow modules (5) where a pallet or two may be depleted each shift. Pallet flow is replenished either by movements from reserve rack (6) or from a bulk floor area (7) that flanks the pallet flow module.

Pickers are voice-directed in the pick modules or use RF for all bulk locations. Unlike picking for store deliveries, where waves are dropped based on a certain number of stores, waves are dropped based on a certain quantity of orders. The system looks at the status of packing stations and builds waves to maximize flow through the facility while minimizing bottlenecks.

The pick module consists of three levels of pallet flow and carton flow, with a spiral conveyor on the end. Totes are routed only to areas where picks are needed. Each level is independent, so levels can be deactivated to save energy or can be serviced without disruption to other levels. The spiral conveyor leads to a merge at the sorter (8).

Pickers cluster pick at each SKU location, picking as much as needed for each wave. The picker is agnostic to whether each item is bound for a single-line or multi-line order.

The facility also offers some value-added services (VAS) (9) that can drive some variations in product flow. Items are occasionally routed to an in-house photo studio that captures images for catalogs. Other VAS areas include key cutting, custom blind cutting, and paint mixing.

A picker might pick a special order blind inside the pick module, which will convey it to a divert lane on the ground level and convey it to the VAS area. In this case the blind is ready to be cut per the customer specifications, and instead of sending processed items back to a packing station, VAS orders are packed out at these locations to avoid passing open tasks to another group.

Non-conveyables (10) are batch picked and taken to a staging location before they are loaded onto outbound trailers (11). If part of a multi-line order, the item is married together with its conveyable counterpart and moved to the loading area.

Putting/consolidation: Single-line orders are conveyed to 24 pack stations on a mezzanine (13). Multi-line orders are processed through light-directed put walls. For instance, a tote with 20 cordless power drills destined for 20 single-line orders is routed to one of the single-line pack stations. The tote is scanned at the pack station area and one drill is packed for each of the orders. An identical tote bound for multi-line orders is routed to the put wall area. There, the associate on one side of the put wall scans the incoming tote. Lights then identify the right put wall cubby for each of the 20 drills.

The associate repeats that process with the next tote. The first item of a multi-line order might sit in the put wall for a few minutes before it is married to remaining items, but the process is designed to flush put walls completely at least hourly. Once all of the items for an order have been put to the wall, a light indicates to the associate on the other side of the put wall that the order is ready to pack.

On the inbound side, as many as two pickers at a time deposit their clusters of SKUs into one of 40 cubbies per put wall. When volume is lower, the “putter” might also move to the other side of the put wall and assume the role of packer. The facility’s 12 put walls can consolidate 480 multi-line orders in each wave.

Packing/shipping: Because picking methodologies are synchronized to the put walls and pack areas, shifts are staggered so that receiving starts early but the facility’s pack stations are busiest later in the day as the last orders come in and the trailers prepare to close.

Once a single-line or multi-line order is complete, a packer scans the tote containing a completed order, is directed to the appropriate sized box, and inserts dunnage. In some cases a shipping label is affixed directly to the product, and a couple of stations are configured for heavy repack tasks like toilets that need foam and boxes marked fragile.

After it is packed, the associate seals the carton and puts it onto a takeaway conveyor to the sorter (8), which will divert to parcel lines or further down to the less-than-truckload (LTL) line (12). Cartons are then married with any non-conveyables in the order and loaded onto trucks.

System Suppliers

Intelligrated: Integration, warehouse control system, conveyor, sortation, put wall, pick-to-light, packaging

Manhattan Associates: Warehouse management & yard management software

Vocollect by Honeywell: Voice picking

Frazier Industrial: Rack & pick modules

The Raymond Corp.: Lift trucks

Motorola Solutions: Mobile computing & bar code scanning

Nestaflex: Accumulation conveyor for floor-loaded parcel lines

Related: Home Depot Builds an Omni-Channel Supply Chain

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up