ChatGPT is a popular topic of discussion, but how can such technology help manufacturers and other robotics users? Groundlight last week announced the launch of its visual understanding service based on natural language instructions.

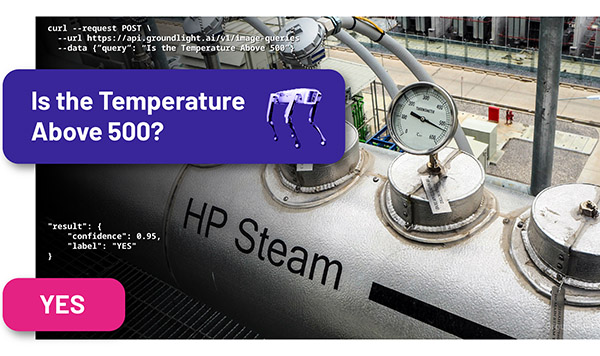

The Seattle-based artificial intelligence startup claimed that its service enables any developer to understand images programmatically using simple English-language instructions and just a few lines of code. Groundlight said its platform can be easily integrated into applications such as industrial automation, process monitoring, retail analytics, video stream analysis, and robotics. This pilot service is now available to select customers.

“As the most powerful AI models get better, there is the tendency to think that all you need is a large language model [LLM],” said Leo Dirac, co-founder of Groundlight. “While they make great demos, robust commercial systems need real human judgment to handle edge cases reliably. And massive LLMs are too slow and expensive to be relied on in isolation for many applications.”

“Groundlight's approach seamlessly ties together traditional deep learning with massive foundation models, edge computing, and real-time expert human supervision,” he added.

Groundlight emerges from stealth

Amazon AI veteran Dirac and Microsoft Hardware alumnus Avi Geiger co-founded Groundlight in 2019. The company emerged from stealth with $10 million in new funding led by Madrona, with participation from Greycroft Partners, Founders Co-op, Flying Fish, AscendVC, and EssenceVC.

Groundlight asserted that its “platform empowers any developer, even those without data science experience, to quickly build robust vision solutions.”

Previously, developers would have to gather and label a dataset, train a model, and then figure out a machine learning operations (MLOps) system to maintain it. This process could easily take months, noted Groundlight.

By contrast, the company said it lets developers “get going in minutes by simply describing their visual task in natural language, which is instantly turned into an application-specific model.” Groundlight said it tracks the confidence of this model and continuously optimizes it using feedback from expert human monitors.

Machine learning for smaller manufacturers

Groundlight said its technology enables small and midsized manufacturers to quickly activate machine learning systems to increase productivity. For instance, Austere Manufacturing in Washington state produces lightweight cam buckles designed for high performance and endurance.

“Quality control, process efficiency, and continuous improvement are crucial to our success,” said Uriel Eisen, founder of Austere Manufacturing. “We're excited to use Groundlight to inspect our products and monitor our processes without the development overhead of a typical industrial solution.”

“[Groundlight's] API enables a $10 camera and a few lines of code to implement a working solution in minutes,” he added. “[That's] far less time than we’d spend to even evaluate an expensive industrial computer vision product.”

In addition, Groundlight said its system is applicable to companies with large retail and warehouse footprints. Implementing the same machine learning system in a new environment often means starting from scratch with data collection and training, noted the company.

Groundlight said it allows users to start getting relevant results immediately. They can ask questions such as “Is the USPS mail carrier in the lobby?” or “Is there more than one customer waiting in line?” This is better than sifting through a list of potential similar queries and wading through the false alerts from a generic model such as one that detects a person in an environment, the company said.

“So many ML projects don’t even get off the ground because of the big effort and scarce expertise required to credibly investigate the feasibility of a solution, much less implement it,” said Thomas Stubbs, ARC Labs, Slalom Consulting. “Then they require operational expertise to keep them running. Groundlight has the potential to change all of that.”

Tim Porter, managing director, Madrona, added: “The newest generation of foundation models are incredibly powerful, but they are both expensive to operate and unreliable for many use cases. Every company has unique data, especially in industrial applications.”

“Groundlight’s approach enables companies to utilize off-the-shelf cameras and inexpensive equipment to quickly build and reliably operate customized models,” he said. “We are excited to work with this brilliant team as they build the company.”

Article topics

Email Sign Up