Collaborative robot arms can gain more axes of motion, making them useful for new applications. Festo Corp. yesterday announced that it will show its UR+-certified multi-axis system at Automate 2023 next week in Detroit. The company said it adds up to four axes beyond the six axes of Universal Robots' cobots.

Islandia, N.Y.-based Festo said its multi-axis system features the Festo Motion Control Package (FMCP-UR), which is a complete motion-control panel for up to four axes. The FMCP is fully integrated with the UR cobot control panel and human-machine interface (HMI), and it includes an enhanced safety I/O handshake and communications interface, noted the company.

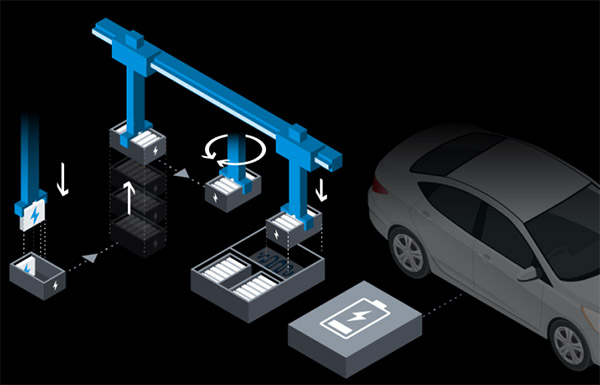

“The FMCP-UR can control turntables, gantry systems, conveyors, transfer tables, and any combination of linear and rotary servo axes up to the 10th axis—all under the UR+ partner umbrella,” said Festo. It said it plans to display full 10-axis motion at Automate, which runs from May 22 to 25.

FMCP-UR can be tailored to the application

The FMCP-UR has specific features to interface with Universal Robots' systems while allowing future flexibility for users, claimed Festo. The company added that its Customer Solution Team can customize the FMCP-UR to the application.

“Streamlined axis configuration allows for less engineering, integration, and troubleshooting during set up and can be easily done through the UR HMI,” it said. “The Multi-Axis Drive (MAD) controller is a URCap software that allows users to set position, speed, and acceleration on the HMI or use the toolbar to jog the axes in manual mode to configure motion.”

The 10-axis UR demo at Automate will also feature the Festo Essentials Pin Ball Maze. The unit of Esslingen, Germany-based Festo welcomed attendees to test their skills to complete the maze using wireless tablet controls.

Festo to show Simplified Motion Series

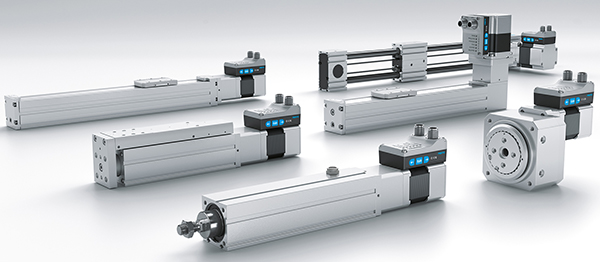

Festo will also show at Booth 1026 the Simplified Motion Series (SMS) of electric actuators.

“SMS combines the simplicity and cost-effectiveness of pneumatics with the benefits of low energy consumption and precision positioning of electrics,” said the company. “SMS actuators deliver infinitely variable three-position motion for an economical all-in-one servo-motion solution.”

The SMS series includes ball screw, toothed belt, mini slide, electric cylinder, piston rod, and rotary actuator styles for a wide range of applications. Festo asserted that the simple setup ensures fast startup and nimble changeover.

CPX-AP-I delivers decentralized I/O

In addition, Festo touted its Ethernet-based CPX-AP-I decentralized I/O. Integrators, OEMs, and end users can network up to 500 I/O modules on a single bus node and mix and match both electrics and pneumatics on the same I/O network for greater flexibility and to develop unique systems, it said.

A free online configuration tool can speed design, while plug-and-play performance can reduce wiring and shorten installation time, Festo said. CPX-AP-I is compatible with the leading communications protocols, including Ethernet/IP, PROFINET, and EtherCAT to enable the Festo ecosystem’s connectivity.

Festo Didactic to debut at booths

For the first time at Automate, Festo Didactic, the company's educational unit, will present at its booth. “The joint appearance of Festo and Festo Didactic illustrates the importance the company places on workforce development as North American reshoring accelerates,” it said.

Festo Didactic will show new online learning portal—the Festo Learning Experience, or Festo LX. It focuses on the growing need for more individualized learning, said the company.

Festo LX provides modular resources for technical training. These resources can be individually assembled into courses and entire learning paths. Varied formats, such as videos, animations, simulations, and text units can help participants remain engaged, said Festo Didactic.

Existing courses can be modified as desired to meet the employer’s or school’s requirements, it noted. New content in text, image, or video format are easily added, according to the company.

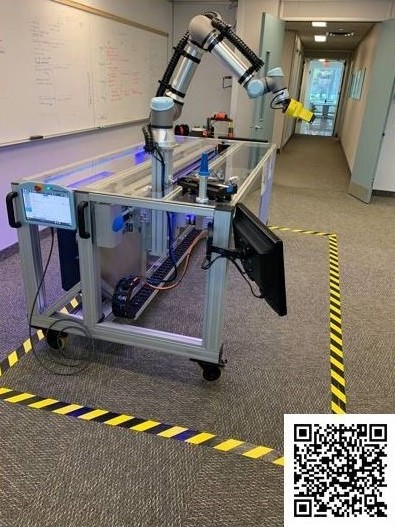

Beyond Festo's booth, Festo Didactic will have Robotic Manufacturing Production System (MPS) training stations at AUBO Robotics USA, Booth 4413, and SICK Inc., Booth 1332. The MPS is used to teach the core competencies of robotic material handling and vision.

The MPS stations will be outfitted with a 360-degree Safety Awareness package that consists of two area scanners tightly integrated through a safety PLC. To facilitate training, Festo and SICK said they developed a training curriculum covering the basics of robot safety and risk mitigation using an easy-to-follow six-step method.

Festo presents at conference

At 10:00 a.m. EST on Wednesday, May 24, Festo plans to present a session on “When and Where to Use Cartesian Robots” in Room 330A of the Huntington Place Convention Center. The presentation focuses on key application considerations for Cartesian robots, including payload, reach, speed, degrees of freedom, environment, end-of-arm tooling, and commissioning.

Festo Didactic will also give presentations. The first covers artificial intelligence and real-time data at 2:30 p.m. on Tuesday, May 23, in Room 330A.

Ted Rozier, director of digital, advanced technology, and robotics at Festo Didactic, will describe how organizations can unleash the power of AI based on real-time data from robotics and automated manufacturing components.

He said he will discuss the types of data that must be captured, the kinds of solutions most applicable to AI, the technical competencies educational institutions can integrate into their curriculums, and the skill sets that will enable frontline workers to thrive in an AI environment.

In addition, Rozier will present during the A3 Educator Networking Luncheon held by the Association for Advancing Automation (A3) on Thursday, May 25. Attendees will hear about Industry 4.0 technology trends, the importance of data, the competencies required to thrive in this new environment, and tips for beginning the training journey.

“From large organizations to mom-and-pop shops, manufacturers use automation and data exchange among robotics and machines to maximize uptime, shorten lead times, and reduce scrap,” Rozier said. “To thrive within the fourth industrial revolution and the emergence of applied AI manufacturers, workforce professionals and educators must understand the key challenges and adjust career pathways to be successful.”

Editor's note: For more about Automate, visit Robotics 24/7's special coverage page.

Article topics

Email Sign Up