FANUC America, an automation solutions provider, is expanding its CNC training offerings to include 5-axis simulation.

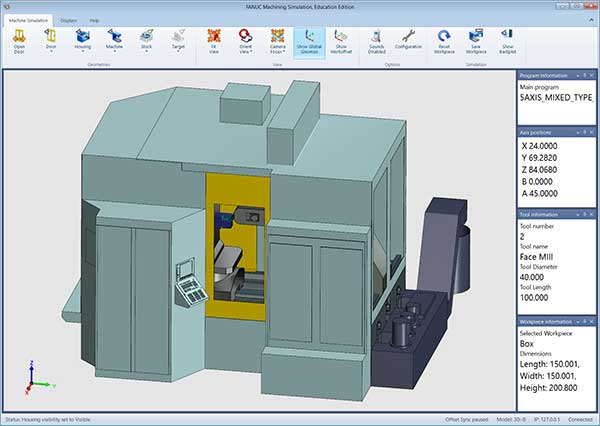

FANUC’s Machining Simulation for Workforce Development provides training for controls operation and part programming in a virtual environment. The Complex Milling Extension option combines FANUC’s CNC Guide and simulation software that can now operate as one of the three main five-axis mill kinematics. The offering also includes training on a three-axis mill and a two-axis lathe for maximum configuration flexibility. Via a digital twin, the five-axis machining simulation allows users to learn how to setup and operate three common advanced five-axis milling machines: mixed type, tool type and table type.

FANUC is committed to working with industry as well as educational partners to help fill the growing five-axis training demand.

The addition of five-axis simulation offers an immersive environment to practice and understand advanced machining techniques. Since five-axis machining involves more complex machine setups, the simulation software effectively teaches users how to take advantage of the options and features. Additionally, the five-axis machining simulation software allows operators to experiment with and prove out the machine setup and/or part program before modifying the actual machine.

Sources: Press materials received from the company and additional information gleaned from the company’s website.

About the Author

Press releases may be sent to them via [email protected]. Follow Robotics 24/7 on Facebook

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up