FANUC Corp. yesterday said it has added three new models to its CRX line of collaborative robot arms. The company said it now offers 11 models of CR and CRX cobots to help companies add automation.

“Our CRX cobots are designed for every type of manufacturer—small or large—looking to expand their capabilities and overcome labor issues,” said Eric Potter, general manager of FANUC America Corp.’s general industries and automotive engineering groups. “With the addition of these new models, we offer the most extensive lineup of easy-to-use cobots available on the market today.”

FANUC America is a subsidiary of Japan-based FANUC Corp. that provides CNC systems, robotics, and factory automation products. Rochester Hills, Mich.-based FANUC America has facilities across the U.S., as well as in Argentina, Brazil, Canada, and Mexico.

CRX cobots designed for ease of use

FANUC claimed that its collaborative robots are safe, easy to use, reliable, and suitable for a wide range of applications, including inspection, machine loading and unloading, packing, palletizing, vision-guided pick and place, sanding, and welding.

The CRX robots can detect external forces in the workspace, stopping safely when making contact with a person or object. This technology allows the cobots to work safely alongside people without the need for expensive guarding.

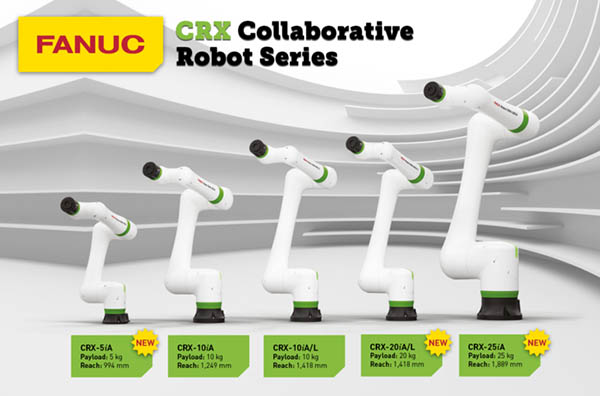

FANUC said its new CRX-5iA, CRX-20iA/L and CRX-25iA collaborative robots can handle payloads of 5, 20, and 25 kg (11, 44, and 55.1 lb.), respectively. They join its existing CRX-10iA and CRX-10iA/L models, which have 10 kg (22 lb.) payload and a reach of 1,249 and 1,418 mm (49.1 and 16.4 in.), respectively.

The series also supports several FANUC features including the iRVision vision system, said the company. While most cobots have a lightweight and compact design, FANUC said its CRX line also offers industrial ruggedness.

“FANUC’s family of CRX cobots offer the same intelligence and reliability as our yellow robots have for 40 years,” added Potter. “When you consider everything our CRX cobot series offers, including eight years of maintenance-free operation, it’s a great choice for customers looking to minimize costs and increase productivity.”

FANUC provides training, integration

In addition, FANUC's interactive programming enables collaborative robot users to teach points using hand guidance or a tablet interface with drag-and-drop icons.

The company offers CRX e-Learning training modules to help operators. Online tutorials include a product overview with features, unboxing and setup, programming, and iRVision courses. Registration for the free training is available online.

CRX cobot models are designed to be easy to connect to third-party devices, including FANUC-approved CRX device suppliers for end-of-arm tooling (EOAT), grippers, accessories, and plugins. Industrial automation suppliers interested in having their products become part of the CRX device program should contact FANUC.

Demos and shipping to come

FANUC plans to demonstrate all five CRX models at IREX (International Robot Exhibition) Virtual from March 1 to 18, and at IREX from March 9 to 12, at the Tokyo Big Sight in booth E4-04.

The company said it will begin shipping production units of the new CRX-20iA/L in April. The CRX-25iA and CRX-5iA robots will be available in June 2022.

Article topics

Email Sign Up