Dobot Robotics last week opened its U.S. office in Dallas, following its global expansion strategy. The Shenzhen, China-based company also launched its CRA series of collaborative robots and the associated VX500 Smart Camera in the U.S. market.

Dobot said the new products expand its range of high-performance, easy-to-use cobots for companies in industries such as electronics, automotive, and metal processing.

“The Dallas office functions as the headquarters for Dobot’s North American operations, encompassing a showroom, training center, logistics hub, and service centers,” said Alla Huang, general manager of Dobot USA, in a release. “Leveraging our U.S. subsidiary, we are committed to enhancing support for our local partners and customers, delivering top-notch products and services, and continually strengthening our presence in North America.”

Dobot also today announced a partnership with VenHub Autonomous Soluutions Inc. for smart retail stores.

Dobot designs CRA series for industrial uses

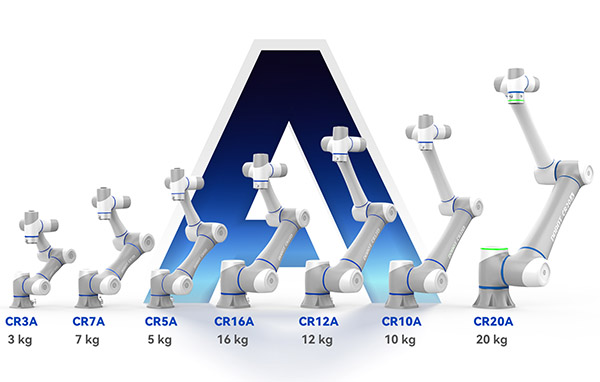

The new CRA series includes seven models with maximum payloads from 3 to 20 kg (6.6 to 44 lb.) and a working radius of 620 to 1,700 mm (24 to 66 in.). Dobot said the cobots are suitable for high-precision industrial applications such as pick and place, sorting, screwing, inspection, gluing, welding, transporting, polishing, and palletizing.

Compared with the previous model, the CRA cobots offer a more powerful gearbox that shortens a work cycle by an average of 25%, according to the company. The control boxes of the devices are also about 25% smaller.

The boxes can come with optional IP54 protection for challenging environments, reducing the need for extensive maintenance in the long term, said Dobot.

Cobots come with safety, communications features

In addition, electromagnetic brakes can stop the gripper arms from descending within 18 milliseconds, protecting workers in the immediate vicinity even during power outages.

Dobot noted that its 3, 5, and 10 kg models are compatible with its self-developed SafeSkin technology. It can detect obstacles within a radius of 15 cm (5.9 in.) and avoid collisions, it asserted.

The CRA series supports Modbus, Ethernet/IP, and Profinet communication and connects with PLC (programmable logic controllers) and other automation systems. With 24 available I/O ports and PNP/NPN switching, expansions can be carried out more easily, Dobot said.

The cobots' operating software, also new, supports graphical programming, scripting, and drag-to-teach for trajectory replay. It is designed to be user-friendly and compatible with diverse end devices, from PCs to tablets, said Dobot.

VX500 Smart Camera to open new applications

The new VX500 Smart Camera uses Dobot's proprietary 2.5D spatial compensation technology. This enables equipped robots to more accurately detect tilted or angled objects, explained the company.

This technology opens up a variety of vision-based automation scenarios for cobots of the new CRA series as well as the existing CR series, it noted.

Dobot added that users can set up the new camera quickly and easily with its latest software.

Article topics

Email Sign Up