Dobot is showing off its new high payload collaborative robot at Hannover Messe in Germany this week. The new CR20A cobot has a 20 kg, or 44 lb., payload capacity, a 1,700 mm, or 66 in., wide working radius, and ±0.1 mm repeatability.

The Shenzhen, China-based company said the robot is suitable for heavy load handling, packaging, and palletizing, as well as large-sized workpiece machining and long-seam welding in complex scenarios.

Hannover Messe is hosted and organized by Deutsche Messe AG. This year's industrial trade show runs from April 17 to April 20 and features more than 2,500 exhibitors and some 66,4000 attendees.

CR20A has minimal residual vibration

Based on new-generation technology and advanced dynamic algorithms, the CR20A's residual vibration is reduced by 50% during high-speed stops and has enhanced reliability to greatly improve production efficiency in heavy-load scenarios, the company said.

Dobot noted it has developed dedicated process package software for palletizing, welding, and other complex tasks. By combining CR20A, users can customize and deploy the solutions with a few simple setup steps, it claimed.

Dobot implements brake mechanism to enhance safety

The CR20A features an electromagnetic brake protection mechanism, which automatically engages in the event of a power outage, preventing the robot's end tool from falling and ensuring no displacement occurs during start-up and shutdown.

In production applications, the robot's actual load may change due to process adjustments. To avoid problems caused by significant load deviations, the CR20A has a load auto-detection function, the company said.

Dual-end effector design allows for greater flexibility

The CR20A has a dual end effector connector design that allows it to connect directly to multiple end effectors and be used with a wide range of third-party accessories. The CR20A supports Ethernet/IP and Profinet, seamlessly connects with other automation systems via PLC, and has 24 channels of universal IO ports that support for PNP/NPN switching.

The company highlighted the benefits of the cobot arm when compared to traditional industrial robot arms, noting the new cobot is easy to deploy and set up.

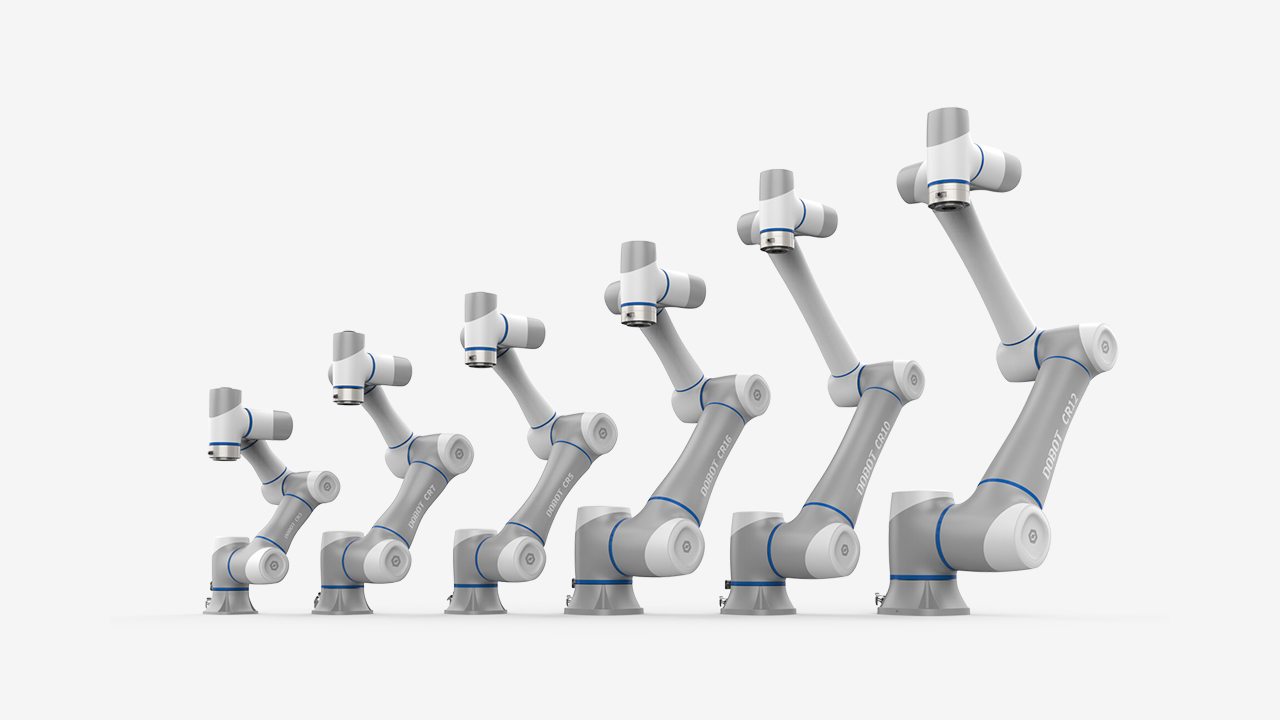

In other related Dobot news, the company recently announced that it had partnered with automotive parts manufacturer Team LeMans to develop the DOBOT AUDI R8 LMS race car. The vehicle was used at the first qualifying round for the Super GT 2023 Series at the Okayama International Circuit. Featured on the car is a picture of Dobot's CR Series.

The company said it partnered with the automotive maker to introduce the Dobot brand to the Japanese motorsports industry.

Editor's note: This article has been updated with an additional photo of the CR20A.

Article topics

Email Sign Up