Bridgestone Corp. today announced that it has started a proof of concept for soft robot hands to automatically perform piece-picking tasks at logistics sites. The company said it will seek to achieve small-scale commercialization of soft robotics created with various partners during its next Mid Term Business Plan, from 2024 to 2026.

“From the perspective of the declining birthrate, aging population, and the need to avoid contact between people due to the COVID-19 pandemic, there is rising demand for automation in areas where people work, which is drawing attention to soft-robotics that can collaborate together with people,” stated Norikazu Otoyama, general manager of the Soft Robotics Business Preparation Office at Bridgestone.

“Through its tire business, Bridgestone has continued to support the mobility of people and objects from the ground up,” he added. “With its legacy in tire business, we look forward to creating new value together with various partners through our soft-robotics business in the future.”

Tokyo-based Bridgestone employs approximately 130,000 people globally and conducts business in more than 150 countries and territories worldwide. The company said it offers a diverse product portfolio of premium tires and innovative technologies for safe and sustainable mobility.

Bridgestone branches into soft robotics

Bridgestone said its soft robotics business follows its corporate goal of “contributing to a society that ensures accessibility and dignity for all” as described in its “Bridgestone E8 Commitment.” The diversification capitalizes on its core competencies of mastering rubber and road contact, as well as its development and production know-how for tires and hoses, said the company.

As it explores new business models for commercialization, Bridgestone said it is developing rubber actuators, or artificial muscles. The company, whose U.S. headquarters are in Nashville, Tenn., said its actuators offer flexibility, impact resistance, light weight, and high power.

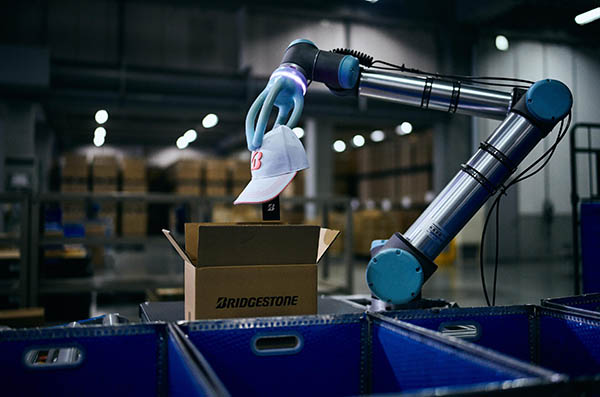

Soft robotic arms and hands with these characteristics can automate the process of picking and transporting individual items. Bridgestone said they can help address social and customer challenges such as labor shortages and demand for “contactless” interactions.

Partners work on proof of concept

In July, Bridgestone began a proof of concept (PoC) with wholesalers of daily necessities and various items, robot manufacturers, and other partners. In it, soft robot grippers used Bridgestone rubber actuators to automate piece-picking processes in logistics warehouses.

It is difficult for a single conventional robot to pick up objects with various shapes, levels of rigidity, and weights, such as tubes, bottles, and pouches. A single soft robot hand equipped with Bridgestone's rubber actuators, meanwhile, can achieve “just the right” grip of various objects, claimed the company.

Bridgestone said it plans to continue the PoC with its partners in pursuit of the quick practical application of soft robotics to piece-picking applications. Among them is Tokyo-based Ascent Robotics Co., which is providing the Ascentpick artificial intelligence for image recognition.

“It would not be an exaggeration to say that co-creation forms the basis for all of Bridgestone's exploratory businesses,” said Otoyama. “I believe that gaining understanding from our partners regarding our business to create new social and customer value and to start the PoC at the site of a partner represents a large step forward in the soft-robotics business.”

Bridgestone noted that it is looking at new businesses such as recycling, soft robotics, and guayule (a natural source of latex). It is exploring technology and business models in new fields where it can use its core competencies to achieve sustainable growth.

In addition, the company said it is seeking to foster entrepreneurs and talent interested in starting new soft robotics projects “unbound by past conventions as an internal venture.” Bridgestone said it is looking to develop diverse talent and rapidly bring its soft robotics to market.

Article topics

Email Sign Up