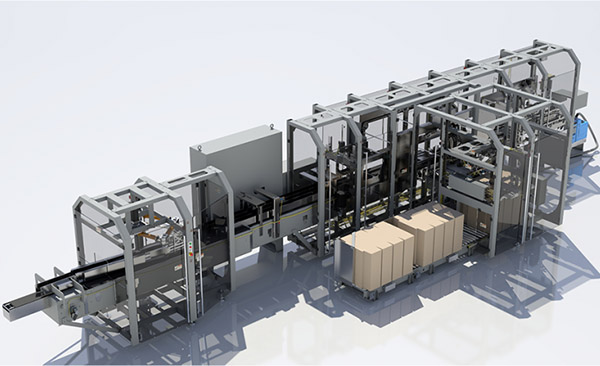

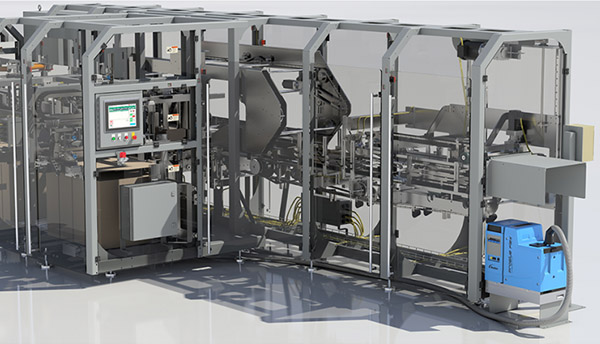

Brenton LLC claimed last week that its new XCP Series continuous motion case picker is engineered to enable fast, consistent changeovers, including easy access to all critical areas of operation. The ProMach Inc. brand said the case packing system is suitable for applications up to 70 cases per minute and will be on display at PACK EXPO.

“The goal with the XCP Series was to launch a continuous motion case packer that innovatively reflected the needs of today’s market and clients,” said Landen Stoker, vice president and general manager of Brenton, in a statement. “We captured direct feedback from our customers while collaborating with other ProMach product brands to ensure we designed best-in-class operator and maintenance access that created a changeover optimized for uptime in today's SKU-prolific marketplace.”

Brenton designs and manufactures integrated end-of-line packaging systems, specializing in case packing and palletizing using robotics and automation. The Alexandria, Minn.-based company also said it has more than 30 years of experience providing materials handling and pick-and-place systems for the food and beverage, consumer packaged goods, pharmaceutical, and medical device industries.

As part of ProMach's End-of-Line business, Brenton said it “helps packaging customers protect their reputation and grow the trust of their consumers. Covington, Ky.-based ProMach has 46 brands and facilities worldwide.

XCP designed with customer feedback

Brenton Engineering said it designed the XCP Series with the customer in mind. The company added that its engineering team focused its XCP design on ease of operation, troubleshooting, and access – three attributes that it said are key to long-term success.

“The XCP Series embodies a more aesthetic design that is intuitive to operate and maintain, making it the ideal case packer for numerous industries and applications in 2023 and beyond,” asserted Brenton. “It is designed to run wrap around cases and trays for products in bottles, jars, canisters, cups, and other rigid packaging for the food, personal care, chemicals, and beverage industries.”

As a result of customer feedback and research and development, Brenton said its new case packer offers the following advances:

- Changeover repeatability – XCP is designed to provide faster, more consistent changeovers.

- Easy access – Operators can access all important areas of the machine and be within 6 in. of the corrugate blank at all operator-side entry points.

- Faster delivery – The system has a standardized main design with a customized infeed to target a shorter overall lead time.

- Intuitive HMI – The human-machine interface features two-touch navigation to most commonly used functions.

- Ergonomic blank load system – The conveyor feed case blank loading system accepts three 26-in. stacks of blanks at a time.

The XCP Series includes the XCP-30, XCP-40, and the XCP-C30, which are customized versions of the case packer. Brenton said the addition of the XCP Series to its case-packing portfolio “gives customers a reliable option with speeds reaching up to 70 cases per minute that is competitively priced and ready to perform.”

Brenton at PACK EXPO 2023

Brenton plans to demonstrate the XCP in Booth C-3822 at the Las Vegas Convention Center for PACK EXPO from Sept. 11 to 13.

Attendees can also also see an integrated stack-and-wrap palletizing solution featuring a FANUC CRX-25iA with a 30 kg (66.1 lb.) payload. This collaborative robot will be programmed with Brenton’s new pallet-building software, which enables users to edit pallet and slip sheet dimensions, as well as define and edit layer patterns, build configurations, and product type.

The demonstration will showscase the expertise that Brenton and Orion, another ProMach product brand, have in robotic palletizing and stretch-wrapping applications.

Editor's note: For more information about PACK EXPO, visit Robotics 24/7's special coverage page.

Article topics

Email Sign Up