Earlier this year, researchers at Lawrence Livermore National Laboratory (LLNL) announced they had 3D printed transparent glass at room temperature.

In addition to being a breakthrough in generating transparent glass structures, the innovation could also allow the creation of glass structures with composition gradients. The technology could be used for everything from high-powered lasers to printing lenses for eyeglasses.

“The Lab is always looking for different ways to create new materials for optical applications,” said LLNL chemical engineer and project lead Rebecca Dylla-Spears. “We’re not going to replace the optical materials made through traditional means, but we’re trying to impart new functionality using additive manufacturing. This is the first step to being able to print compositionally graded glass optics.”

“The Lab is always looking for different ways to create new materials for optical applications,” said LLNL chemical engineer and project lead Rebecca Dylla-Spears. “We’re not going to replace the optical materials made through traditional means, but we’re trying to impart new functionality using additive manufacturing. This is the first step to being able to print compositionally graded glass optics.”

The LLNL team worked with scientists from the University of Minnesota and Oklahoma State University.

Existing methods for printing glass either require high temperatures, product inconsistency or opaque results. (You can read more about glass printing here and here.) The LLNL approach involves first printing the object using an ink with glass particles suspended in it. Thermal treatment then densifies the object to ensure transparency and uniformity. This is followed by an optical quality polish.

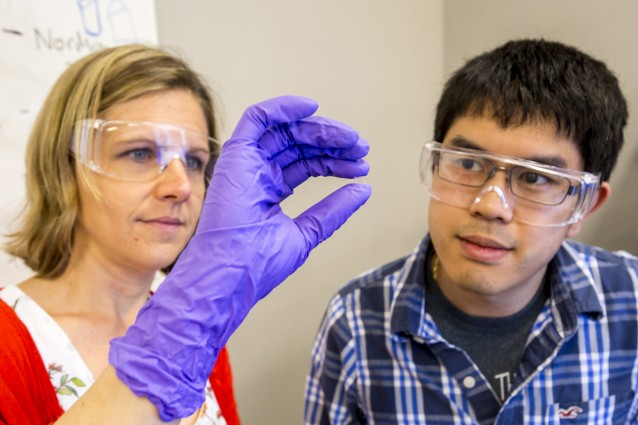

LLNL researchers Rebecca Della-Spears and Du Nguyen were part of the team that printed transparent glass at room temperature. Image: LLNL

LLNL researchers Rebecca Della-Spears and Du Nguyen were part of the team that printed transparent glass at room temperature. Image: LLNL“For printing high-quality optics, you shouldn’t be able to see any pores and lines, they have to be transparent,” said LLNL materials engineer Du Nguyen. “Once we got a general formulation to work, we were able to tweak it so the material could merge during the printing process. Most other groups that have printed glass melt the glass first and cool it down later, which has the potential for residual stress and cracking. Because we print at room temperature, that’s less of an issue.”

The refractive index of the object can also be changed using this method. Lenses could be printed in a flat format, rather than the traditional curved lens format used in most optical applications.

“Polishing complex or aspheric lenses is pretty labor-intensive and requires a lot of skill, but polishing a flat surface is much easier,” Nguyen said. “By controlling the refractive index in the printed parts, you alter the bending of light, which enables a lens that could be polished flat.”

The printing process could also be used for creating glass microfluidic devices with complex layouts.

You can read more about the technique in Advanced Materials.

Source: Forbes

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up