Large-scale 3D printing specialist BigRep has formed a partnership with Bosch Rexroth, a supplier of drive and control technologies. BigRep’s 3D printers will be equipped with CNC control systems and drives from Bosch.

“Across industries, customers are looking for reliable, controllable and efficient 3D printers in order to manufacture top quality parts,” said BigRep CEO Stephan Beyer. “As BigRep is the first to integrate CNC-grade control systems in 3D printers, we will re-define additive manufacturing. The Rexroth controls are also an excellent platform for providing our 3D printers with full connectivity for existing production and automation systems. This will establish 3D printing as a key industry 4.0 application.”

“This partnership demonstrates that Bosch Rexroth is constantly developing sustainable technologies and new factory automation solutions for the factory of the future,” said Thomas Fechner, director of the new business unit at Bosch Rexroth.

BigRep has had a busy year when it comes to partnerships. In February, the company announced an agreement with BASF to develop new industrial 3D printing materials for its large format printers. BigRep is also working with Etihad Airways Engineering in the United Arab Emirates to create additive manufacturing solutions for the aerospace industry. The two companies plan to print cabin parts and concepts for new aircraft and for retrofitting existing aircraft.

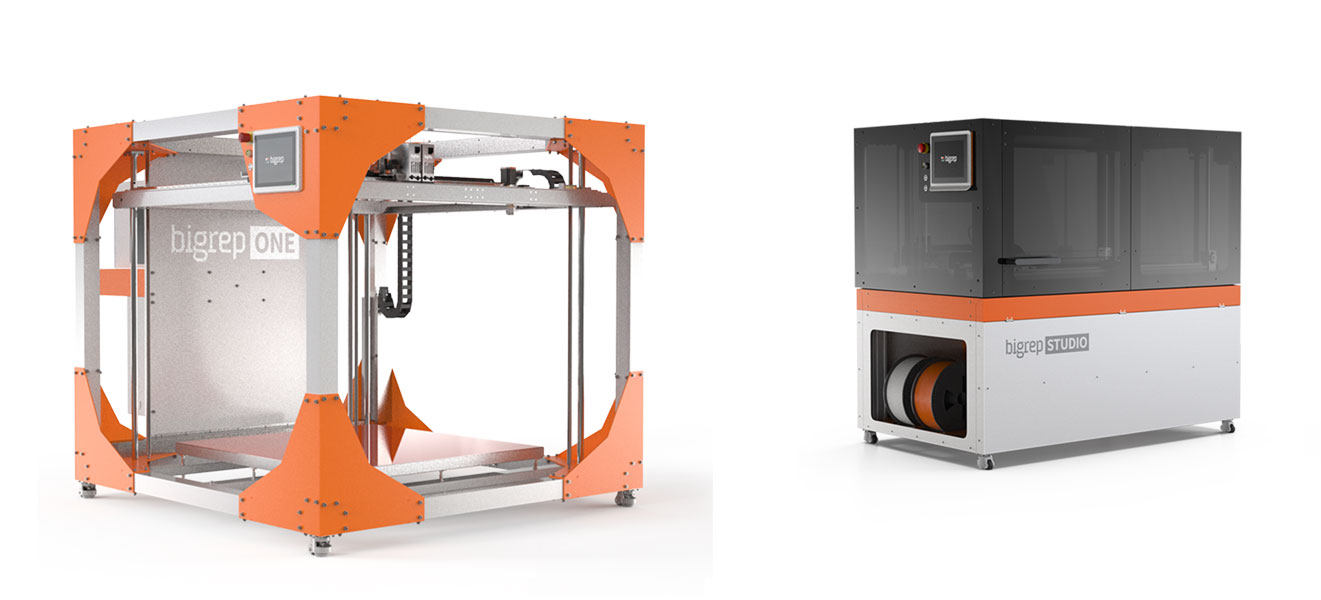

This past spring, BigRep also unveiled a new 3D-printed wheel rim to demonstrate the capabilities of blending additive manufacturing with high-end design. The wheel rim was created by product designer Marco Mattia Cristofori. It was printed on the BigRep ONE machine using temperature resistant PRO HT filament.

Bosch Rexroth has previously worked with voxeljet on 3D printing solutions as well.

Source: BigRep

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up