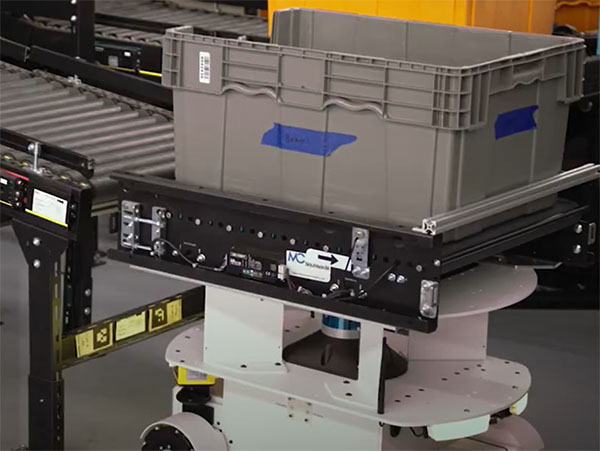

Berkshire Grey Inc. and Locus Robotics Corp. yesterday announced that they have integrated Berkshire Grey's Robotic Shuttle Put Wall, or BG RSPWi, with the Locus Origin and Vector mobile robots. The companies said their “end-to-end” automation will help retail and e-commerce customers maximize supply chain productivity and throughput and address growing labor challenges.

“Partnering with Berkshire Grey allows our customers to reap the benefits of enterprise-level robotic automation across some of their most business-critical supply chain processes,” stated Mike Johnson, president at Locus Robotics.

“Berkshire Grey and Locus Robotics have been operating in the supply chain industry for many years now, and it’s great to see us join forces to deliver seamlessly integrated, proven, and impactful automation solutions that help our customers grow and succeed, now and into the future,” he said.

Wilmington, Mass.-based Locus Robotics said its autonomous mobile robots (AMRs) collaborate with human workers to double or triple order-fulfillment productivity, reduce operational costs, and improve workplace conditions. The company said it supports more than 100 brands and has deployed AMRs at over 250 sites worldwide.

Locus Robotics looks to help maximize throughput

Ongoing labor shortages and inflation are putting growing pressures on supply chain and distribution frameworks, said Berkshire Grey and Locus Robotics. Retail and e-commerce businesses are struggling to keep up with growing customer demands while managing these pressures and keeping operational costs in control, the partners added.

The companies said their customers are “demanding flexible and seamlessly integrated best-of-breed robotic automation solutions to address these challenges and deliver top-quality customer experiences.”

Berkshire Grey and Locus Robotics explained that the integration of BG RSPWi with Locus Origin and Locus Vector is intended to help maximize throughput by doing the following:

- Delivering a fast and packaged solution for order fulfillment and store replenishment

- Processing a wide range of SKUs, surpassing SKU coverage of other alternatives

- Enabling a fully-automated, end-to-end supply chain ecosystem

- Augmenting supply chain operations with optimized labor and costs

Berkshire Grey explores more integrations

Berkshire Grey and Locus Robotics are also exploring future integrations of Berkshire Grey’s Robotic Product Sortation (BG RPS), Robotic Shuttle Product Sortation (BG RSPS), and Robotic Pick and Pack for eCommerce Autobagging (BG RPPi).

With this package of robotics offerings, businesses could fully automate their order fulfillment, autobagging, and store-replenishment processes while seeing immediate return on investment (ROI) and throughput improvements, they said.

“We have seen a growing number of customers asking for solutions that they can deploy holistically versus piecemeal innovation,” said Steve Johnson, president and chief operating officer of Berkshire Grey.

Locus Robotics has a distinct value proposition in enabling greater flexibility in the supply chain industry with their robotic automation solutions,” he said. “Now with Locus Robotics, we believe we can take our combined solutions to a wider market.”

Berkshire Grey said it combines robotics and artificial intelligence to automate fulfillment, supply chain, and logistics operations. The Bedford, Mass.-based company said its systems “transform pick, pack, move, store, organize, and sort operations to deliver competitive advantage for enterprises serving today’s connected consumers.”

Berkshire Grey's customers include Global 100 retailers and logistics service providers.

Article topics

Email Sign Up