ABB is showcasing its line of collaborative robots, connected application cells, and mobile robots at Automatica 2022 this week in Munich. The company said its technologies are playing a major role in the shift away from fixed production lines to flexible robotic cells in response to unprecedented changes in consumer demand.

Zurich-based ABB is putting on demonstrations at Booth 231 in Hall B5 to highlight how its systems can help users with their manufacturing, logistics, and operational needs. The company added that it will share insights on its strategy and expansion of complete application cells.

Designed to significantly speed time-to-market and enhance flexibility, these systems are helping businesses meet changing market needs, claimed ABB.

RobotStudio goes virtual

ABB said its dedicated RobotStudio zone features virtual and augmented reality demonstrations of how software can simplify programming and operating robots. The demonstrations will show how the tools can be used to design, test, and refine entire production cells in a virtual world, enabling users to avoid the time, cost, and disruption that would be incurred in a real production environment.

ABB has created a digital trade-show portal at https://automatica.events.abb.com where visitors will be be able to visit its virtual showroom, which includes all the products featured on the stand plus ABB’s complete portfolio of robotic systems. Its cobots include the GoFa and SWIFTI product lines.

The company yesterday hosted a roundtable discussion where it discussed its latest generation of robots and unveiled a new automated workcell. Speakers included Marc Segura, ABB Robotics president; Andrea Cassoni, ABB’s managing director; and Andie Zhang, head of the global business line for general industry and collaborative robots.

ABB launches new OmniVance cell

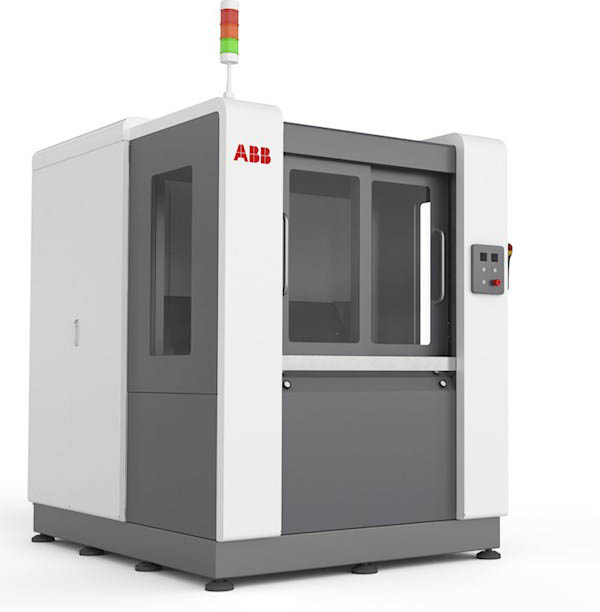

Earlier this week, ABB launched its OmniVance Machine Cell, an integrated system designed for a diverse range of machining applications. The company said the product is the first to market that can perform up to eight different applications in one cell.

An IRB 2600 robot, a controller, and a turntable combined with pressure and level sensors and other equipment make up the OmniVance Machining Cell. The cell also comes with ABB’s Machining Software to integrate auto-calibration and path-tuning functions into a single tool.

The Machining Software calibrates tools and work objects automatically, reducing re-calibration time from four hours to just 10 minutes, the company claimed. Integrated path tuning functionality enables users to easily edit thousands of path points in just half a day, compared with the two days typically needed to obtain a high-quality surface such as that of a cellphone case or an aluminum wheel.

Article topics

Email Sign Up