Chip suppliers within the Apple Watch supply chain have begun “gearing up” to start production for Apple’s new device, according to a new report from Digitimes.

Chip orders are estimated to be around 30 - 40 million units for a debut in early 2015.

Digitimes had previously reported, prior to Apple’s September 9 event, that the device was at the engineering verification test stage and needed to complete product verification testing before entering mass production. It appears that the Apple Watch has now passed that milestone and is beginning to enter mass production for its debut in early 2015.

Apple Senior Vice President of Retail and Online Stores Angela Ahrendts had previously revealed that the device would debut in Spring 2015, with several reports indicating that Apple was aiming for Valentine’s Day 2015 as a potential launch date.

Apple Watch pricing will start at $350 for the aluminum version, while the stainless steel and gold editions will reportedly retail for prices starting at $500 and $4,000 respectively.

Will Apple’s Supply Chain Be Able To Sustain Demand For Smartwatch?

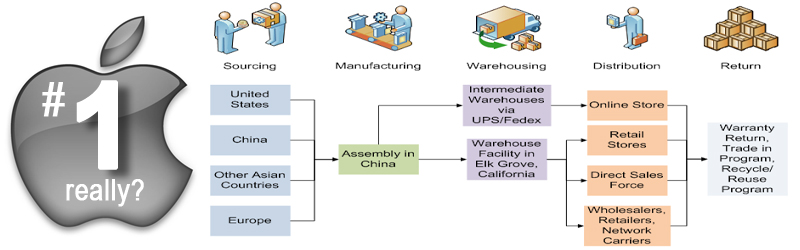

One particular issue that recently received a lot of attention from procurement management experts is involved the setbacks Apple encountered in regard to its supply chain.

First, the hardware developer’s suppliers experienced a problem in which the iPhone 6 and iPhone 6 Plus failed to emit the appropriate amount of light. Then, after the two smartphones were released, Apple customers discovered the devices were bending in their pockets.

The two primary issues

Now, according to Manufacturing Business Technology contributor Paul Noël, Apple is finding its partners aren’t producing the iPhone 6 and iPhone 6 Plus in tandem with consumer demand, resulting in shortages across the board. With this factor considered, it can be concluded that Apple is facing two central problems:

1. Quality Control: Not too long ago, Apple had a reputation for producing near-flawless goods that operated on a superb level. The latest reports regarding the new iPhone seem to contradict this image, signaling that Apple’s development and quality assurance teams aren’t paying as much attention as they used to.

2. Purchasing: One can perceive Apple’s product shortages as a problem rooted in two issues. In one respect, it’s possible that the company’s procurement officers aren’t aligning themselves with Apple’s sales department, meaning they’re not receiving accurate demand reports on which to construct device orders. From a different angle, it’s possible that Apple’s purchasing division is overlooking factors that are preventing its suppliers from producing goods at the optimal rate.

With respect to both points, it may benefit Apple to consider the benefits of business process outsourcing to conduct a thorough review of the enterprise’s supply chain. Such companies can serve as quality control experts, as well as investigators that can identify which partners are unintentionally causing shortages to occur.

Ready for a new device?

Amid these concerns are tangible signs that Apple is preparing to unveil new products within the next three to four months, and the hardware developer’s manufacturing partners are gearing up. Apple Insider noted the company’s chip suppliers are preparing to initially turn out 30 million to 40 million Apple Watches. The source noted the following supply-related concerns:

- The Apple Watch will run on advanced system-in-package (SiP) technology that allows entire computing systems to reside on a single chip.

- The device will be equipped with a Force Touch Retina surface that is able to identify the differences between a tap and a press.

- Wi-Fi and Bluetooth connectivity are expected to be a part of the final package.

- Near-field communication will assist those using Apple Pay.

Apple Insider acknowledged recent rumors that Apple Watch will debut on Feb. 14 of next year, but this estimate has largely been regarded as speculation. As one can see, a fair number of components are categorized as being the “latest and greatest,” which means that Apple’s supply chain may be sacrificing quality control to ensure the device functions adequately, as opposed to optimally.

Future supplier concerns

In order to avoid future shortages, Noël recommended that Apple diversify its supplier portfolio, alleviating primary partners of production demands that, in some cases, are unrealistic. According to Noël, one of the reasons why the iPhone 5S and 5C didn’t encounter the deficit woes associated with the latest iPhone releases is that Apple used two different manufacturers, Foxconn and Pegatron, to handle the assembly of the 5S and 5C respectively.

Now, Foxconn is handling much of the iPhone 6’s production on top of managing all of the manufacturing needs of the iPhone 6 Plus. Alleviating some of the pressure on Foxconn will mitigate the shortage issues with which Apple is currently contending. As far as quality assurance goes, it’s best if Apple sends development professionals to manufacturing.

Sources: MacRumors and Strategic Sourceror

The Desperate Struggle at the Heart of the Brutal Apple Supply Chain

The most valuable corporation on Earth has the power to make or break a company through its supplier relationships.

External link: theguardian

Related: Is Apple’s Supply Chain Really the No. 1? A Case Study

Article topics

Email Sign Up