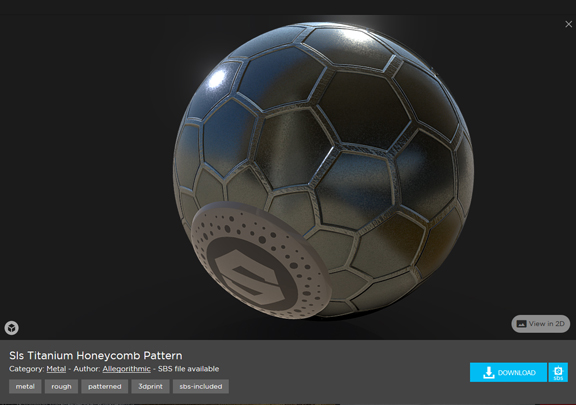

SLS Titanium Honeycomb, shown here, is among Allegorithmic’s newly released rendering materials for visualizing 3D-printed designs.

SLS Titanium Honeycomb, shown here, is among Allegorithmic’s newly released rendering materials for visualizing 3D-printed designs. SLS Stainless Steel, shown here, is among Allegorithmic’s newly released rendering materials for visualizing 3D-printed designs.

SLS Stainless Steel, shown here, is among Allegorithmic’s newly released rendering materials for visualizing 3D-printed designs.Standalone rendering programs like Keyshot and CAD-embedded renderers like SolidWorks PhotoView 360 usually come preloaded with a library that includes standard manufacturing materials, such as steel, titanium, and plastic. By applying these on your 3D part or assembly model, you can create renderings to visualize how your design will look after manufacturing.

But what if you plan to 3D-print your design?

3D printable materials are quite different from classic manufacturing materials in reflectiveness, stiffness, graininess, and other visual properties. Since 3D printing or additive manufacturing (AM) is now used by many not for prototyping but for full-scale production, visualizing 3D-printing projects should also be possible.

To address this void, Allegorithmic this week releases a collection of 3D printing materials, delivered as part of its materials library Substance Source.

Customizable 3D Printing Materials for Rendering

In the announcement, Allegorithmic wrote, “Each material comes with a specific set of parameters that let users vary their visual attributes. Variations are non-destructive, and range from color and roughness to slice shape and regularity. Printer head variations are also included. Designers and 3D artists from all disciplines, including industrial design, architecture, games and VFX, will find much to explore in the 3D Print collection. As 3D printing expands into new industries, each user type will have a photorealistic way to incorporate real world material characteristics and advanced sci-fi patterns into their designs and projects.”

The list of materials include

- 10+ woven meshes and complex assembly materials made in 3D printing.

- 40+ Materials based on ten 3D print technologies including modifiable parameters such as layer topography, alterations and variations related to the printing process.

Connection to CAD

Allegorithmic wrote, “The possible variations range from color and roughness to slice shape and regularity, as well as random printer nozzle micro-spills of material amount and distribution.”

While customizing material properties such as reflectivity, roughness, and texture grains may be second nature to digital artists who work with high-end rendering programs, the process may be a significant learning curve for CAD users. Most CAD users ideally want to render their CAD designs in CAD-integrated renderers or standalone renderers with simple interfaces.

“Substance is integrated within CATIA,” said Nicolas Paulhac, product manager of Substance Source at Allegorithmic. “For other software, you can export the material map and plug it [into the software]. For instance, you can export the different maps from Substance Designer and Substance Player and plug them into KeyShot.”

To accurately represent the 3D printing materials, “we actually sourced several 3D-printed physical samples of each [additive manufacturing] technology, including various level of printing precision, quality, and surface finishes, and used these as master reference for the digital materials creation,” Paulhac explained.![]()

The AM-specific materials in Substance Source include SLA Plastic, SLA Clear Resin, SLS Titanium Honeycomb, and more.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up