Aeva today announced it will demonstrate its 4D lidar technology for the automotive industry at Auto Shanghai 2023 – the 20th International Automobile Industry Exhibition from April 18 to April 27.

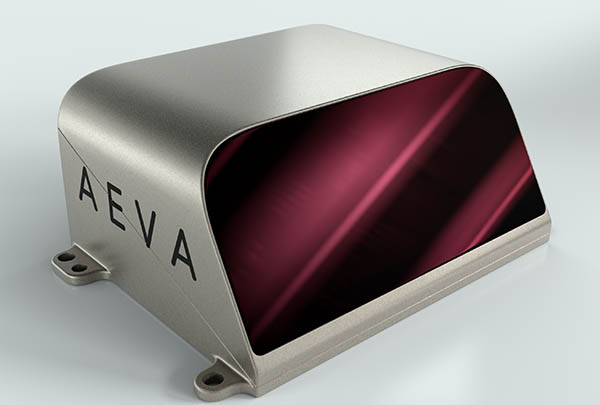

Aeva will demonstrate its Aeries II sensor and 4D lidar-on-chip technology at booth 2.2H 2BA012 in the National Exhibition and Convention Center Shanghai.

Visitors will learn about the company’s next-generation sensing and perception technology for a range of automotive applications including Advanced Driver Assistance Systems (ADAS) and autonomous vehicles. Aeva will be providing demo drives for select attendees to experience 4D lidar in real-time and on the road.

Aeva 4D lidar delivers sensing and perception performance using Frequency Modulated Continuous Wave (FMCW) technology to directly detect the instant velocity of each point in addition to precise 3D position.

Aeva’s FMCW technology is inherently free from interference from direct sunlight and other lidar sensors while also eliminating retroreflector blooming and ghosting.

Aeries II offers better mapping and perception features

Using the additional dimension of velocity data, Aeva said its sensors provide unique advantages over conventional time of flight 3D lidar sensors including:

- Long Range Performance: Detect, classify and track dynamic objects such as vehicles, cyclists and pedestrians at long distances.

- Ultra Resolution: A real-time camera-level image that provides up to 20 times the resolution of legacy time of flight lidar sensors.

- Road Hazard Detection: Spot small objects on the roadway with greater confidence at up to twice the distance of conventional lidar sensors.

- 4D Localization: Estimate vehicle motion in real-time with six degrees of freedom for accurate positioning and navigation without the need for additional sensors, like IMU or GPS.

Aeries II is the first sensor on the market to integrate Aeva’s lidar-on-chip technology, the Mountain View, Calif.-based company said. It integrates all key sensor components including transmitters, receivers, and optics onto a compact silicon photonics module.

This design uses no fiber optics, resulting in a highly automated manufacturing process that allows Aeva to manufacture at scale and lower costs to meet the needs of automotive OEMs and other volume customers.

Article topics

Email Sign Up