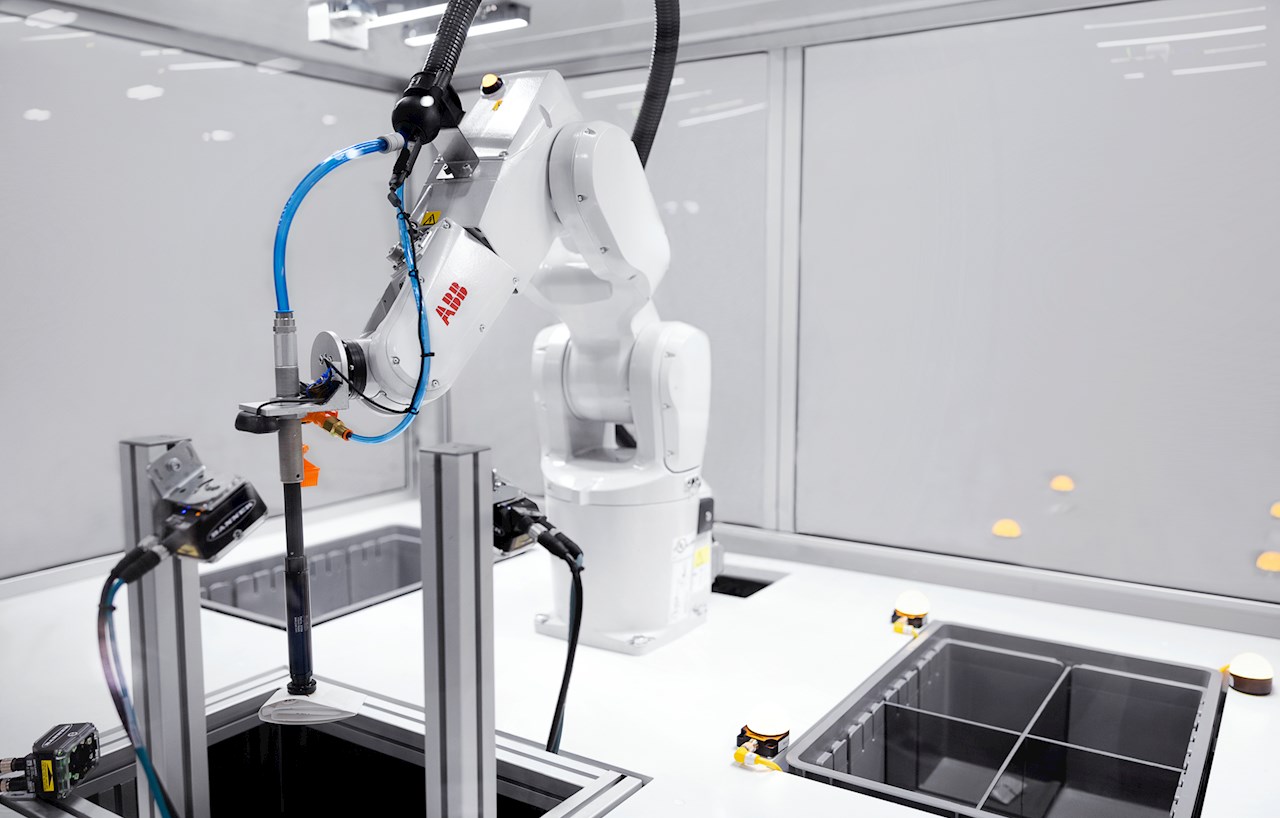

ABB Robotics said it has enhanced its automation portfolio with the launch of the Robotic Item Picker – a new artficial intelligence and vision-based system that can accurately detect and pick items in unstructured environments in warehouses and fulfillment centers.

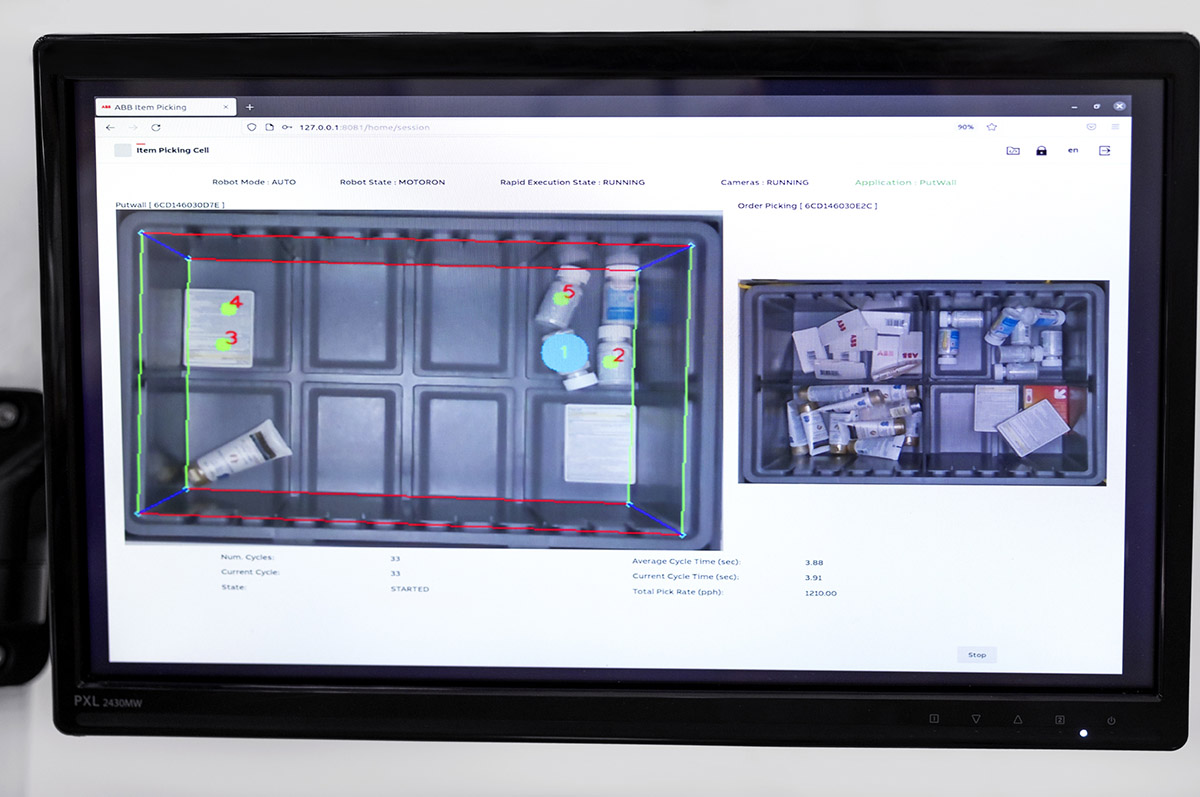

Using machine vision and artificial intelligence, the Item Picker determines the optimal grasp points for each item before the suction gripper picks up and places the item into designated bins, the Zurich, Switzerland-based company said.

ABB Robotics displayed the Item Picker at LogiMAT 2023 at the Stuttgart Trade Fair Centre last week.

“The explosion of e-commerce, changing consumer demands and global labor shortages are driving the need for flexible automated solutions that make order fulfillment and distribution faster and more efficient,” said Daniel Navarro, managing director of consumer segments and service robotics at ABB Robotics.

“With its ability to learn and adapt in constantly changing warehouse environments, our AI-enabled Robotic Item Picker sees items and decides how to pick them, at speed with more than 99.5% efficiency, helping businesses overcome these challenges and build resilience,” he added.

New system can pick up to 1,400 items per hour

The system does not require any human supervision or information about the physical attributes of the items it picks, claimed ABB. With a picking rate of up to 1,400 items per hour, businesses can handle more orders without increasing headcount or time, according to the company.

Featuring a robot, suction grippers, and proprietary machine vision software, Robotic Item Picker fully automates complex picking and placing tasks of a range of items including cuboids, cylinders, pouches, boxes, polybags, and blister packs, which otherwise require the dexterity and flexibility of humans.

Suitable for a range of loads and applications, the Robotic Item Picker can be fitted to one of three ABB robots: the IRB1200, the IRB 1300, and the IRB 2600.

With a payload of up to 3 kg (6.6 lb.) and a reach of up to 1.65 m (64 in.), the Item Picker offers the flexibility required to meet many different needs in order fulfillment and sortation, said ABB.

Item Picker designed to be integrated into existing systems

Already pre-configured and tested, the Item Picker reduces engineering effort and accelerates time-to-market by easily integrating into existing automated storage and retrieval systems (ASRS). These include shuttle, cubic, and 3D storage solutions, said ABB.

In addition to LogiMAT, the company plans to exhibit at Booth 5623 at Automate 2023 later this month in Detroit.

Article topics

Email Sign Up