CHICAGO—Fabtech 2021 here this week provided robotics and other automation companies with the first chance to display their latest fabrication technologies and upgrades to an in-person audience, many for the first time in a couple of years.

Attendance may have diminished since 2019, before the COVID-19 pandemic, but exhibitors at Fabtech 2021 reported strong engagement with manufacturers. With shortages of skilled labor, it's no suprise that interest in automation continues to grow.

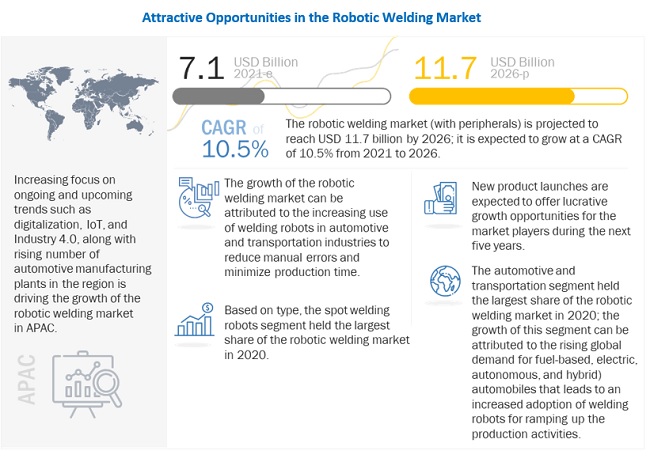

The global market for robotic welding and peripherals could experience a experience a compound annual growth rate (CAGR) of 6%, growing by $2.3 billion (U.S.) between 2021 and 2025, according to Research and Markets. Similarly, Markets and Markets projected a 10.5% CAGR, with the market growing from $7.1 billion (U.S.) in 2021 to $11.7 billion by 2026.

Cobot welders add features

Among the features that collaborative robot providers demonstrated at this year's event were increased reach, vison-based guidance, and interfaces for ease of use. Vendors also touted cable management, new sensors, and greater payload capacities for arc welding and other industrial processes.

“For 40 years, robotic arc welding evolved incrementally,” said Joe Campbell, senior manager of applications development and strategic marketing at Universal Robots. “Collaborative arc welding is the first disruptive technology to hit the robotic arc-welding market since the introduction of DC servo-powered robots.”

He attributed the rapid market traction to several key drivers including a significant shortage of welders, increase in high-mix/low-volume production, and the fact that cobot welders are easy to deploy, quickly producing parts with improved quality and consistency.

See the slideshow for some of the more compelling arc-welding cobots and related technologies on display at Fabtech 2021, in alphabetical order by company.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up