The supply chain for electronics and electrical components is under more strain and demand than ever before, but robotics and automation can give manufacturers the boost they need. The use of robots in electronics manufacturing can result in reduced waste, greater efficiency, and a safer working environment.

Annual installations of industrial automation for the electrical and electronics industry have grown 24%, from 89,000 in 2019 to 137,000 in 2021, according to the International Federation of Robotics (IFR). This makes it one of the biggest users of robots.

Here are five potential advantages from robotics for electronics manufacturers:

1. Rapid quality control

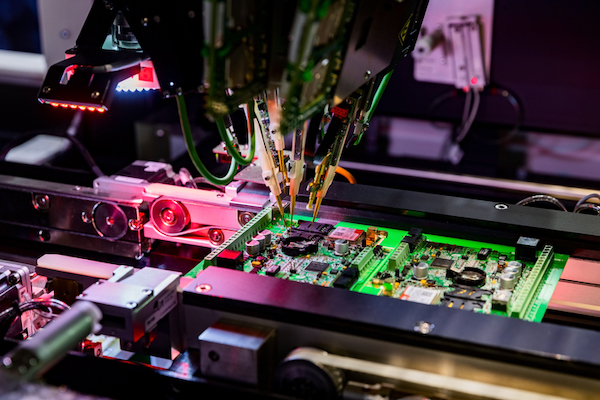

One of the most convenient aspects of using robots is their ability to automate quality-control (QC) inspections. This can be a highly time-consuming stage of the manufacturing process, particularly when dealing with sensitive electronics. Robots can take over QC with the help of artificial intelligence, machine vision, and cameras.

As units move through the production line, cameras can rapidly inspect them. The camera footage goes to a computer vision algorithm, which distinguishes correctly made pieces from defective ones.

A great example of robotic QC is FIH Mobile’s application of Google’s AutoML Vision algorithm. By using computer vision for product inspection, FIH Mobile was able to reduce its undetected defects rate by 75% while also slashing the inspection time required for each unit.

2. More efficient manufacturing

One of the clearest advantages of using robots in electronics manufacturing and testing is improved efficiency. Manufacturers can automate a significant and growing portion of their processes, allowing the production of more units in less time.

This is worth noting, given the ongoing electronics component shortage worldwide, which could last until at least 2024. Resolving this shortage relies on maximizing productivity and “near-shoring” or reshoring manufacturing.

Robots can partially or fully automate the electronics testing process, providing an extra efficiency boost before and after manufacturing.

Some manufacturers are even boosting their efficiency by running fully automated night shifts. Newark, N.J.-based ZAGO applied this exact tactic with robots from Robotiq to meet demand despite staffing shortages. The robots could run for up to 18 hours at a time, mostly unattended.

3. Improved resource utilization

Once programmed properly, robots can repeat the same action innumerable times until shutdown or a mechanical failure. As a result, a robot is much less likely to accidentally damage or waste materials than a manual processes, which inevitably suffer from human error.

This is especially true in the electronics industry, which often involves handling small, delicate parts and completing complex and precise tasks such as soldering.

Italian power tool manufacturer RUPES experienced the waste-reduction capabilities of industrial robots firsthand. It used collaborative robot arms from Universal Robots to achieve this goal, even without prior experience using robots in its workflows.

Handing off electronics manufacturing processes to robots wherever possible can reduce errors and wasted resources. As a result, more resources can be put to use in producing electronic components and ending the supply shortage.

4. Greater safety for workers

Any manufacturing business must have a contingency plan for emergency situations, such as natural disasters or a severe cyber attack. Such plans ensure that employees are safe when they come to work, no matter what may occur during a given day.

Robots can help improve workplace safety, especially for electronics manufacturers. For example, electronics making involves numerous potentially hazardous materials, including heavy metals. While these components tend to be a bigger problem once a product is disposed of, staffers still risk exposure during prodution and testing.

Using autonomous mobile robots (AMRs) produced by Mobile Industrial Robots, Metro Plastics reduced forklift traffic, a significant safety hazard to employees. The AMRs even helped reduce employees’ back pain by eliminating the need to bend over repeatedly to move parts.

5. Greater process visibility

Installing robots at any stage in the manufacturing process is an excellent opportunity to infuse other new technologies, such as Internet of Things (IoT) sensors. These are often necessary to ensure the safe and proper functioning of the robot.

For example, Boston Dynamics’ Spot quadruped robot can use its onboard IoT sensors to patrol a site, collecting and transmitting data. An AI predictive maintenance program analyzes the sensor data in real time to monitor for potential hazards or damages.

The combination of IoT sensors and data directly from robots themselves leads to a buildup of valuable real-time data. Manufacturers can use this information to increase the visibility of their operations.

The data may reveal insights they might have yet to recognize, such as a bottleneck or an area where resources are wasted. This increased visibility allows for improvement and optimization.

Robots are the future of electronics manufacturing

Using robots in electronics manufacturing has numerous advantages, from improved worker safety to greater efficiency and reduced waste. Implementing robots today enables electronics manufacturers to get ahead of the competition and lead the way in manufacturing innovation.

About the author

Emily Newton is a technology writer who enjoys writing about the latest innovations changing our world. Read more of her articles online at Revolutionized Magazine.

Article topics

Email Sign Up