Inkbit, a provider of additive manufacturing solutions, announced the publication of a landmark study in the Nature journal, demonstrating the use of its Vision-Controlled Jetting (VCJ) technology to directly manufacture complex multi-functional systems in one print, without assembly of subcomponents.

Written in collaboration with MIT and the Soft Robotics Lab at ETH Zurich, the paper, titled “Vision-Controlled Jetting for Composite Systems and Robots,” demonstrates how VCJ opens a new frontier in manufacturing by expanding capabilities to synthetically recreate the intricate structure and functionality of natural organisms.

Traditional manufacturing methods struggle to fabricate systems that mirror the intricate structures and varied material properties found in nature. VCJ rises to this challenge, offering the ability to accurately fabricate complex, multi-functional systems in a single print without the need to assemble subcomponents.

“Our VCJ technology is a qualitative change in the field of additive manufacturing,” said Davide Marini, CEO at Inkbit. “We are closing the gap between the elegantly sophisticated structures we admire in nature and our ability to replicate them synthetically. This isn’t just a step forward—it’s a leap into a new era of manufacturing.”

Originated from traditional inkjet 3D printing, Inkbit’s VCJ technology takes it to a whole new level by integrating an AI-enabled 3D computer vision scanning system that captures the print geometry of each layer in real time. This digital closed-loop feedback control operation eliminates the need for mechanical planarizers and enables printing with slow-cure chemistries that build the polymer chain more precisely. As a result, VCJ can directly print intricate, multi-material parts in a wide range of mechanical properties with accuracy and precision.

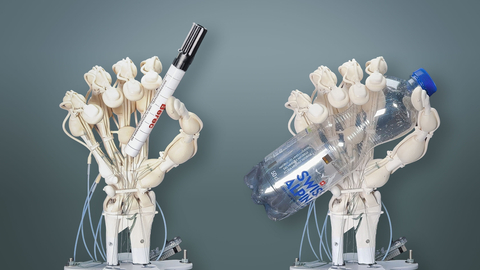

The practical applications of this technology are vast. VCJ not only enhances the resolution and functional capabilities of printed components, it also enables fabrication of intricate internal networks of channels and cavities to carry signals, power, or fluids through the structure. With VCJ, it is now possible to directly fabricate sophisticated, multi-functional systems capable of performing complex physical tasks at scale. To demonstrate VCJ’s capabilities, the authors of the Nature article printed a variety of complex systems, including a tendon-driven hand modeled from MRI data, a pneumatically actuated walking manipulator, a pump mimicking a heart, and novel metamaterial structures.

“With Inkbit’s VJC technology and materials, we were able to print something as complex as a robotic hand with bones, ligaments, and tendons, mirroring a fully functioning human hand, and do so in one go,” said Thomas Buchner, doctoral student at ETH Zurich. “Inkbit’s TEPU material has very good elastic properties and bounce back to their original state much faster after bending than polyacrylates, making it ideal for producing the robotic hand’s elastic ligaments.”

Inkbit's VCJ technology is poised to revolutionize the way we think about product design and manufacturing, especially in fields that require multi-step assembly processes and complex supply chains. The study published in Nature marks a significant milestone in additive manufacturing and opens new possibilities in fields like robotics, healthcare, mobility, industrial automation, and defense.

Read the Nature articleher here.

To learn more about Inkbit’s VCJ 3D printing technology, watch this video.

Article topics

Email Sign Up