Driven by a reliance on automated solutions to conduct repetitive tasks and improve workplace safety, a new report is projecting strong growth for the 3D printing robot market over the next five years.

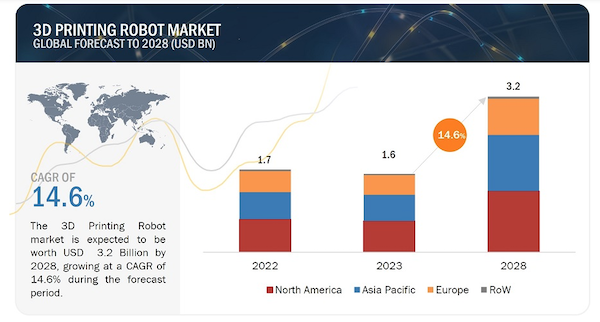

According to a new report, by MarketsandMarkets, the 3D printing robot market is projected to grow from $1.6 billion in 2023 to reach $3.2 billion by 2028, a Compound Annual Growth Rate (CAGR) of 14.6%. Rising awareness about the higher degrees of freedom offered by 3D printing robots compared to traditional printers is a factor in the expected market expansion.

When considering individual components, the 3D printing head segment is positioned for robust growth over the forecast period. 3D printing heads, or extruders, present a host of valuable advantages for additive manufacturing. These heads are versatile, capable of accommodating a broad spectrum of materials, from PLA (polylactic acid), PETG (polyethylene terephthalate glycol), TPU (thermoplastic polyurethane), and ABS (acrylonitrile butadiene styrene) to metals, enabling their application across diverse industries.

Renowned for their precision, 3D printing heads can meticulously create objects in the X, Y, and Z axes, resulting in highly accurate prints with exceptional surface quality. Additionally, their ability to operate at high speeds contributes to shorter production times. Furthermore, these heads exhibit efficiency by judiciously utilizing filament material through controlled deposition. Their user-friendly nature, often arriving pre-calibrated, appeals to both novices and experts, facilitating widespread adoption across industries.

3D printing, particularly in conjunction with robots, is revolutionizing functional part manufacturing across several key industries. In aerospace, automotive, and electronics, the demand for lightweight, durable, and precision-engineered components is met through 3D printing with robots. These robots enable the creation of intricate parts with complex geometries, surpassing the limitations of traditional manufacturing methods. As these robots continue to advance, they are poised to enhance functional part manufacturing in these industries, as well as in consumer goods, energy, construction, and more, promising a future of innovation and efficiency.

The North American 3D printing market is a standout in terms of projected growth. 3D printing robots offer solutions to key challenges in the North American construction sector. They reduce the demand for highly-skilled workers, enhance safety by handling hazardous tasks, cut costs, boost productivity, and elevate project quality. While facing developmental hurdles such as speed and material limitations, these robots hold substantial promise for revolutionizing the construction industry and making it more efficient and sustainable.

For instance, in May 2022, Cornell University's Bovay Lab (New York) integrated ABB's 6,000-pound IRB 6650S Industrial Robot from Switzerland for large-scale 3D printing in construction. This innovation advances robotic construction research, providing students with practical experience and enhancing sustainability and efficiency in the field. The robot, with a 12-foot track, offers a 12-foot circular reach, covering an 8x30-foot area. It is a significant step in utilizing 3D printing robots for construction and enhancing the construction sector in North America.

Watch this video to learn more about Cornell’s work with 3D printing robots.

Article topics

Email Sign Up