Editors’ Picks

Many small and midsize manufacturers have been unable to take advantage of automation because of the cost and technical support required to deploy and maintain the systems. Developers are ramping up efforts to introduce ease-of-use features to make robots more accessible to a broader, more transversal pool of users. Making robots easier to implement and use has helped smaller shops find a home for them on their shop floors. “Ease of use is not just a ‘nice to have’ feature,” said Joe Campbell, senior manager of applications development and strategic marketing at collaborative robot leader Universal Robots. “It’s key to…

The convergence of emerging market trends and recent technological advances has opened the door for autonomous mobile robots, or AMRs, to take on more tasks in manufacturing and supply chain operations. The changes don't stop there, however. Today, adopters of AMRs have begun to shift into high gear, transitioning from pilot projects involving small numbers of robots to “fleet-size” implementations. For example, Zebra Technologies' roller-top AMRs are making inroads into factories, warehouses, and distribution centers (see image, above right). These robots, built on Fetch Robotics' Freight 100 bases, are taking on more and more collaborative roles. This is thanks to…

The stage is set for the reshoring of U.S. manufacturing to finally gain momentum, and the latest generation of robots represents a key element of the equation. The backdrop against which this shift will unfold reflects a new set of economic realities for the industry. Two elements stand out as drivers of change: the rise in offshore wages and the increase in transportation costs, both of which are causing manufacturers to re-evaluate the benefits of maintaining production operations overseas. “Many companies that established operations outside of the U.S. that may be tied to the offshoring wave of the 1980s and…

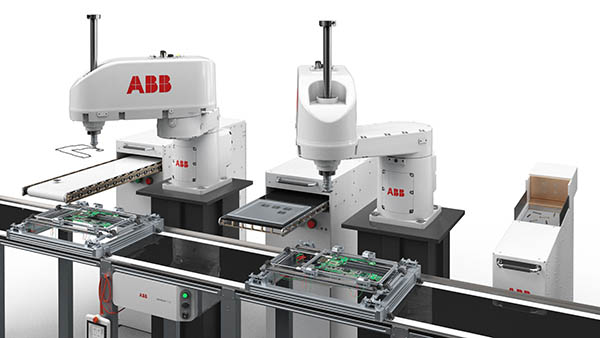

The presence of robots in the electronics industry is not new. What is new, however, is the rate at which manufacturers in this sector are deploying robotics and the applications in which they are using the technology. “We’re seeing accelerated adoption by manufacturers thanks to increased demand for semiconductor products, rising labor costs, and innovations that allow robotics to address new problems,” said Adrian Choy, product manager-robotics at Omron Adept Technologies. Innovations open the door to new applications The recent improvements have helped robots to adapt to the changing manufacturing environments. “As the automation community has evolved, robots have become…

To increase collaborative robots, or cobots, capabilities and broaden their application range, robotics companies are leveraging advances in both vision and motion control systems. One of the most important recent developments in vision technology has been 3D vision. “3D vision systems are becoming very easy to integrate into robot applications and provide much better information for a robotic application than a 2D vision system ever could,” said David Bruce, manager of intelligent products & vision at FANUC America. 3D scanning gives cobots better perception One advancement in vision systems that enhances cobot capabilities is 3D scanning in motion. “Until recently,…

Robotics companies are seeking to advance the ability of their technology to perceive and understand their work environments and by cultivating the capacity to adapt dynamic operating conditions on the fly. This situational awareness is enabled by a synergy between sensors and machine learning. By giving mobile and picking robots more human-like perception of their physical environments, developers are also increasing the level of precision that users can expect from them. This in turn has expanded the range of tasks and services that robots can perform autonomously. “Robotics is often defined as an intelligent connection between sensing and acting,” said…

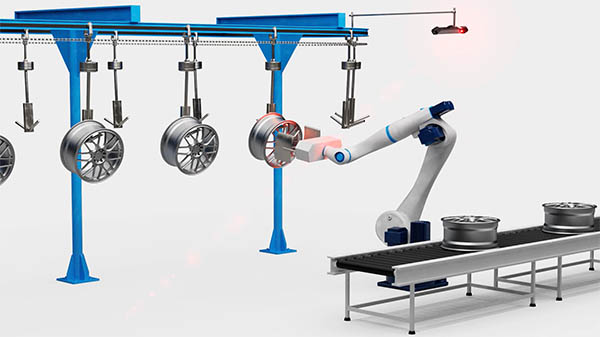

Advanced motor technologies are helping improve tasks robots can perform, helping to make them stronger, nimbler, and more sustainable. Empowered with these enhancements, a new class of robots has begun to take on tasks in industries that haven’t typically taken advantage of automation. Market demand for compact and energy-efficient mobile robots continues to grow. At the same time, advances in automation manufacturing have helped improve today’s motors in multiple ways. Motors advancements bring more accuracy Greg Diek, product manager for motion at Omron Adept Technologies, said a critical area of improvement “is better accuracy while winding the coils for motors.”…

Surgical robots are starting to play a key role in the medical space and are helping increase positive outcomes for both doctors and patients. The promise is that these robots will work alongside surgeons to move from manual laparoscopy to more efficient approaches—expanding the number of patients who can have minimally invasive surgery. Robotic systems are now being used for gynecological, colorectal, thoracic, and urological procedures. Surgical robots benefit patients, surgeons, and hospitals By increasing their use of surgical robots, hospitals can eliminate obstacles and patients enjoy a higher level of care, according to several medical robotics experts Robotics 24/7…

Collaborative robots, or cobots, fundamentally change the nature of production by creating new synergies between humans and machines. By playing to the strengths of people and automation, multiple industries can improve productivity and product quality while reducing operating costs. Equipped with sensors for safe collaboration and accurate manipulation, ways of learning new tasks without programming expertise, and a variety of end-of-arm tooling, cobots can bring flexibility to shops of all sizes. Cobots promise to boost productivity Collaborative robots can perform the dull, dirty, and dangerous tasks once performed by humans. “This provides a double benefit,” said Joe Campbell, senior manager…

Product development teams have only just begun to use artificial intelligence in combination with physics-based simulation platforms, moving beyond advanced automotive applications to more consumer-oriented designs. The use of AI technologies such as machine learning (ML) and deep learning seems like a logical progression, as engineers take on increasingly complex designs and contend with shorter and shorter development cycles. But exactly where does AI fit into the design and development landscape? Does it replace physics-based simulations, or are the two complementary toolsets? A paradigm shift Conventional wisdom contends the use of physics-based simulations will continue to increase, at least nominally.…

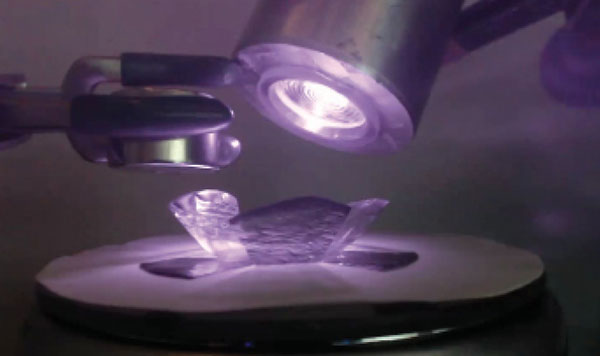

Metal additive manufacturing (AM) stands poised to expand its footprint in the manufacturing sector, transitioning from a proven prototyping tool and small-lot fabrication process to mainstream part production. But there’s a catch. Today’s AM technology isn’t predictable and repeatable enough to be cost-effective for companies that want to use AM to mass-produce parts. Currently, engineers must go through an iterative process of trying different printing parameters before they can identify the combination that will enable them to build parts that meet the necessary quality standards. AM Process Simulation Software Buyer’s Checklist When choosing additive manufacturing (AM) process simulation software, cost…

Robots made exclusively of hard materials prove their worth every day in industrial applications, excelling at repetitive, physically demanding and dangerous tasks that human counterparts cannot take on. Some robotics providers, however, want to steer the design and construction of these machines in a new direction. Driven by robotic use cases in healthcare and cooperative human assistance applications, designers have begun to develop less rigid, more mechanically compliant robots. This new class of machines is constructed of soft materials engineered to mimic properties of soft biological tissue, matching its compliance, elasticity and low density. These properties allow soft robots to…