Editors’ Picks

Found in Robotics News & Content, with a score of 5.42

…appreciate what humans can do, look at highly dexterous manipulation and multi-step complex tasks. Robots can't do them. Also, robots will create far more opportunities for humans than they’ll take. Nobody knew where the Industrial Revolution would go, but most people don't want to go back to the jobs that existed before it. What common misconceptions do Apptronik and other service robotics providers still encounter? Cardenas: Biggest misconception is that people see competition between humans and robots, rather than the possible future of man and machine. Imagine doing your job without a computer or living life without a mobile device.…

Found in Robotics News & Content, with a score of 4.50

…have largely been solved for mobile robots, perception and manipulation remain challenging for piece-picking operations. Advances in computer vision, machine learning, and end-of-arm tooling are now enabling robots to pick at human and even superhuman rates. One company focusing on successful automation of pick-and-place workflows is Material Handling Systems Inc. (MHS). The Mt. Washington, Ky.-based company spun out MHS Robotics from its research and development unit last year. Kristiyan Georgiev, R&D manager for computer vision and software engineering at MHS, spoke with Robotics 24/7 about improvements in robotic picking applications. How long have you been at MHS, and how does…

Found in Robotics News & Content, with a score of 23.37

…robotics and software engineers create, debug, and ship complex manipulation projects faster. “These premium offerings leverage cutting edge approaches that we have developed over seven years working with some of the best robotics companies in the world,” said Dr. Dave Coleman, CEO of PickNik Robotics. “Both MoveIt Studio products ensure customers don’t have to waste time programming common manipulation behaviors. This will further evolve the robotics industry by making it more practical to use advanced manipulation techniques in more applications.” MoveIt Studio can be used for a variety of robotic manipulator applications including those used in space, defense, factory automation,…

Found in Robotics News & Content, with a score of 5.33

…If the application requires extremely fast part handling or manipulation of lightweight parts, or a small working envelope, the delta is a good option to consider. Make way for robot upstarts “The next phase of robotic evolution is in human-machine collaboration, and the introduction of the collaborative robot (cobot) is a major innovation in automation,” said Rockwell. Cobots allow workspaces to be more flexible, enabling humans and robots to work in tandem. Autonomous mobile robots (AMRs) also offer the benefit of working alongside human operators while automating low value-add processes like material handling. Both types of robots are designed with…

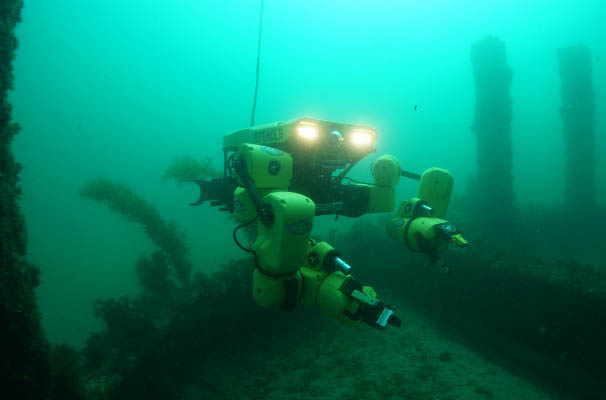

Found in Robotics News & Content, with a score of 8.75

…and government-facing customers with data collection, analytics, and subsea manipulation capabilities to support and maintain assets. It claimed that it can also significantly reduce their operational footprint, operating cost, and greenhouse gas emissions while improving offshore health, safety, and environmental exposure. Shell and Nauticus said they will collaborate with experienced inspection tooling service providers, integrating their technology into Nauticus’ robots and services. After completing an initial feasibility study for the phase-gated project, the team will focus on remote operations of the robotic duo with supervised autonomy and tool control. The collaboration will use Nauticus' acoustic communication network as part of…

Found in Robotics News & Content, with a score of 12.84

…realized it would require a combination of mobility and manipulation to achieve it. Ninety percent of warehouses are still manually operated today, so we saw an opportunity for a flexible robot that could help improve warehouse safety and productivity while accelerating the flow of goods throughout the global supply chain. We focused our initial development efforts for Stretch on trailer and container unloading because it’s the most challenging and physically punishing task in the warehouse. At this stage, we’re just beginning to deploy production robots with early-adopter customers like DHL Supply Chain, Gap, H&M, and Performance Team – A Maersk…

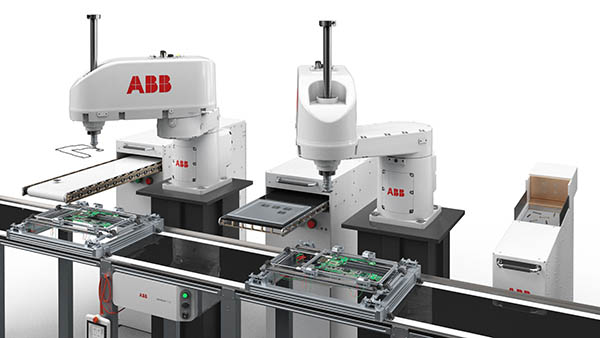

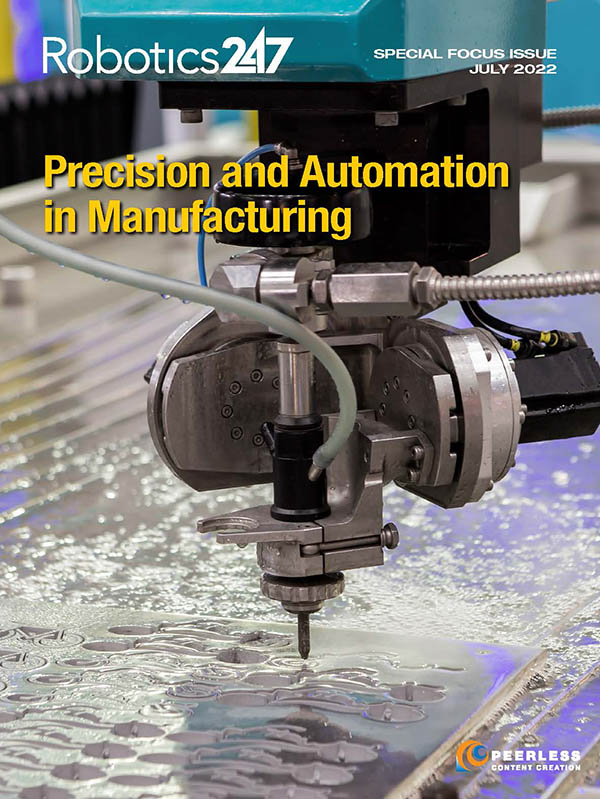

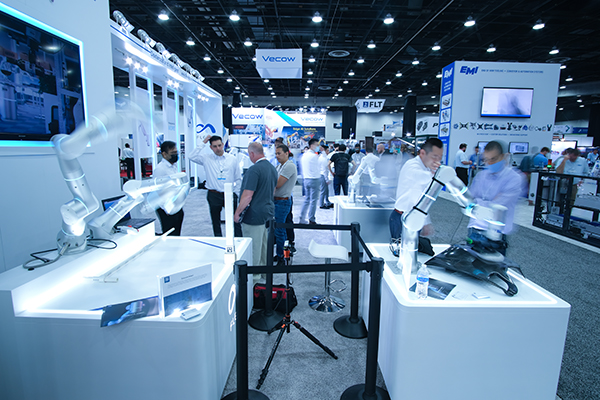

Found in Robotics White Papers & Archives, with a score of 18.87

…also focus on recent advances in machine vision, robotic manipulation, and control software. The download will consider how the latest developments in grippers, robot arms and other systems, and machine learning can provide superhuman levels of precision. While a general-purpose robot may still be science fiction, specialized models are already transforming manufacturing. Topics covered include: Enabling developments in machine vision, motion control, and drives Evaluating different types of robots for precision Award-winning designs as examples for the future of robots and vision End-of-arm tooling and grasping Noteworthy systems from the recent Automate and Automatica trade shows The need for solid…

Found in Robotics News & Content, with a score of 3.51

…to these different use cases, but to the appropriate manipulation with a given end effector.” Take a step back from visual “wow factor” of the latest in warehouse automation and robotics, and it is really software at the WES and analytics levels that will allow users to flex multiple zones of automation to current demand patterns and rapidly changing resource availability, vendors agree. Most WCS software can’t optimize the overall DC like WES can, explained Laura Bickle, senior offering manager for WES at Honeywell Intelligrated, a major provider of warehouse automation and related software. “The WCS system is focused on…

Found in Robotics News & Content, with a score of 14.44

…to successfully achieve a variety of fine and large manipulation skills, including squeezing a pair of tweezers and grasping larger objects. Each finger conforms to the shape it is grasping, enabling it to securely hold objects upon contact. RE2's STARFISH gripper with tactile sensors. Source: Sarcos RE2 is developing this technology with Dr. Veronica Santos, director of the Biomechatronics Laboratory at UCLA, and Dr. Jonathan Posner, professor of mechanical engineering and chemical engineering at the University of Washington. The professors' teams designed the multimodal tactile sensor skin that enables the grippers’ sensorized fingertips to feel normal and shear forces. “When…

Found in Robotics News & Content, with a score of 7.04

…Vision provides power for robotics University researchers are imaginatively exploring ways in which machine vision can inform robotics movement, manipulation, and task planning, from fashion photography and fruit tending to chess. This is just a mere sampling of the ways in which researchers are combining vision technology with robotics to produce new capabilities. Despite their use in many manufacturing, logistics, and warehouse tasks, they're by no means mature, with many more applications to come.

Found in Robotics News & Content, with a score of 6.86

…will also be able to simulate robotic navigation and manipulation, as well as build a test environment to validate robotics applications continually.” NVIDIA works to close 'reality gap' With its NVIDIA Omniverse applications, the Santa Clara, Calif.-based company has focused on ever more realistic simulation and digital twins to accelerate artificial intelligence for robots. “This follows our strategy for end-to-end robotics,” Andrews told Robotics 24/7. “We segment the intersection of robotics and AI into four phases of development: No. 1, train with Isaac Replicator and synthetic datasets. No. 2, simulate with digital twins, which are the focus of today's release.”…

Found in Robotics News & Content, with a score of 11.33

…more about the benefits of remote controls. Flexiv team members described how its systems can be used in medical manipulation, hazardous materials, and service scenarios.