Editors’ Picks

Found in Robotics News & Content, with a score of 7.01

…Market Research. Furthermore, robots can enable applications including drilling, welding of aircraft components, and handling of aircraft parts. Emerging technologies that are part of Industry 4.0, such as artificial intelligence, the Internet of Things (IoT), and augmented and virtual reality, will boost global market trends, said the research firm. In addition, the growing demand for smart mobility will contribute to aerospace robotics revenue. The global aerospace robotics industry could garner revenue worth nearly $9.2 billion by 2030, predicted the Allied Market Research study. Aerospace robotics trends In addition to launching new robots in pursuit of global market leadership, several aerospace…

Found in Robotics News & Content, with a score of 10.75

…automotive technicians, computer support technicians, construction electricians, machinist/CNC technicians, welding/fabrication technicians, medical assistants, and more, the college said. Besides teaching those entering the workforce, the center will also be open to individuals already working in the field looking for additional training or credentials. “The fields of automation and artificial intelligence are evolving and expanding, creating new and exciting careers to meet the needs of today and drive change for the future,” GRCC President Charles Lepper said in a statement. “GRCC is proud to work with our partners in the government, like Senator Peters, and with employers for an Automation and…

Found in Robotics News & Content, with a score of 9.64

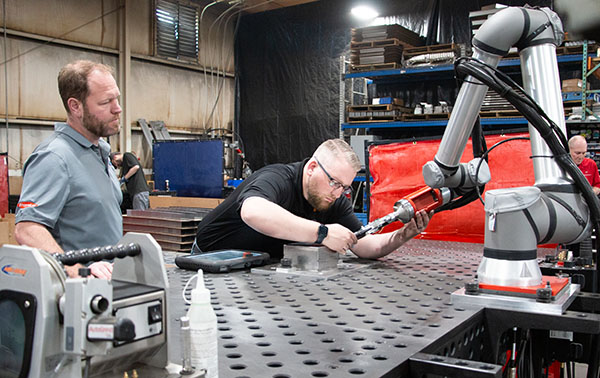

…globally. The company provides systems for applications including arc welding, assembly, coating, dispensing, material handling, material cutting, material removal, packaging, palletizing, spot welding, and clinical laboratory specimen processing. Rapid Robotics also works with Universal Robots Rapid Robotics last week announced that Universal Robots A/S will supply collaborative robots for Rapid's deployment of workcells across North America. The companies said this will enable them to serve more customers and maintain the rapid deployment times they've come to expect, even as Rapid Robotics expands its U.S. footprint. “As the number of unfilled, critical manufacturing roles increases and global economic uncertainty continues to…

Found in Robotics News & Content, with a score of 12.03

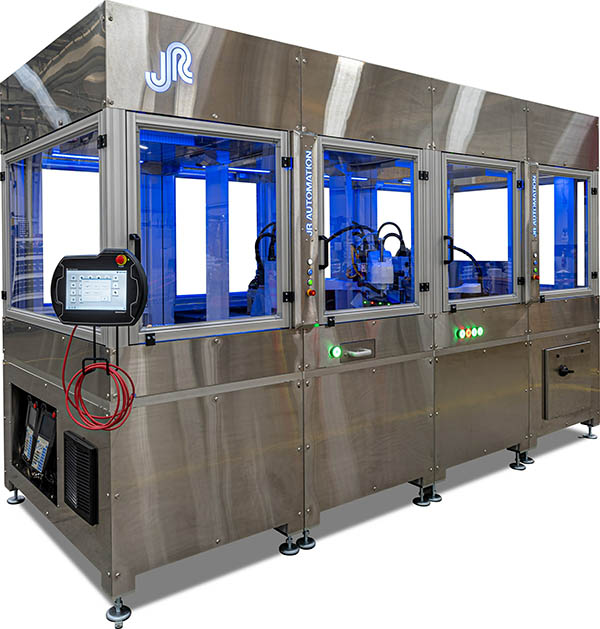

…goods, and electronics manufacturing markets. Assembly capabilities include: Ultrasonic welding Riveting Screwing Snap fit Gluing UV gluing Decorating, Heat Sealing, Joining dissimilar materials Material joining capabilities include: Heat/ultrasonic foil sealing Laser tacking Laser ablation Laser or ultrasonic cutting and die cutting FlexChassis’ configurability enables a range of use cases FlexChassis also includes full digital control and process monitoring. Additionally, linear motors give FlexChassis speed, accuracy, and operational flexibility with multiple configurations through a human machine interface recipe selection. From UL and CE to FDA and Gamp5, the FlexChassis design can be tailored to match specific production requirements. For clean manufacturing…

Found in Robotics News & Content, with a score of 9.87

…efficiency, and applications for other materials and processes. Rapid Welding of Thermoplastic Composite Structure Source: Raythenon Technologies Principal Investigator: Raytheon Technologies Research Center Project Team: Carnegie Mellon University, Wason Technology LLC, and Collins Aerospace Project Description: Lightweight carbon fiber reinforced thermoplastic composites (CF-TPCs) are internationally recognized as a material capable of meeting the future aerospace market high-rate demands and providing sustainability benefits. One key contributor to the rapid manufacturing rate of CF-TPCs is its capability to be welded instead of using traditional time-consuming adhesive bonding and or mechanical fastening. Currently, three heat generation methods dominate the application and development of…

Found in Robotics News & Content, with a score of 12.73

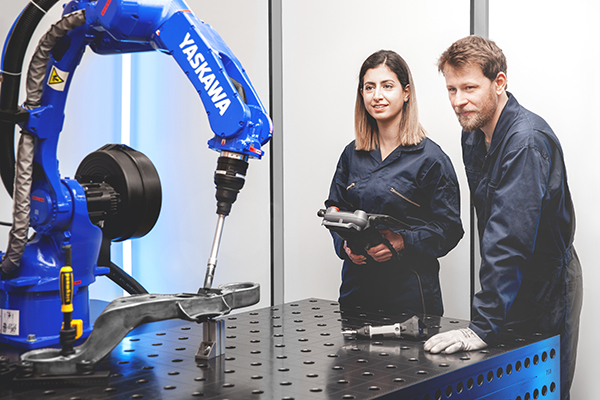

…company. For instance, a user can trace a new welding path on the workpiece with the TracePen input device in the hand and recorded by the software at the same time. The recorded path can then be edited, tested, and executed via the intuitive 3D user interface of the teaching app, Wandelbots said. The software automatically generates the manufacturer-specific robot code in accordance with current safety standards. To train the robots accordingly, companies need only the Wandelbots software and the TracePen, the company said. They can use them to implement numerous robot applications, such as welding, gluing, and material processing…

Found in Robotics News & Content, with a score of 22.35

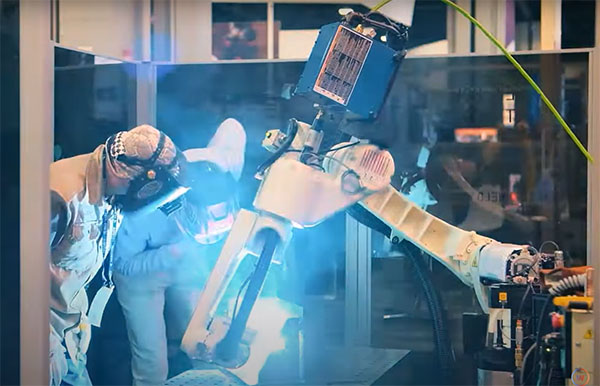

…special training within one day. ABAGY also surveyed the welding community to learn about worker attitudes toward robotic welding. “Every single day, we hear from manufacturers that they can't find people,” said Dmitry Golitsyn, co-founder and chief technology officer of ABAGY. “According to American Welding Society research, more than 40% of welders are over 45 years old. To address this welder shortage, we can help people who are already in the industry become more productive with new technology.” While robots are commonly seen as being useful only for the mass production of thousands or millions of identical items, such as…

Found in Robotics News & Content, with a score of 5.47

…contractors) On industrial sites for transportation of industrial insulation, welding and sandblasting equipment, mechanical material, and tools (customers: industrial service providers, general contractors, owners of refineries and chemical/nuclear/power plants, etc.) We'll start collecting data, not only from our hardware, but also from other tools, sensors, and solutions available on-site. ... Simultaneously, we'll keep expanding in terms of automating on-site logistics by introducing robotics solutions for further steps of the process—loading, unloading, reloading, horizontal material-transport tasks, etc. Will you be hiring in North America as part of your expansion? Kuchukov: We are currently in the process of setting up a service…

Found in Robotics News & Content, with a score of 5.30

…strong growth in process and path-intensive applications, such as welding and surface finishing. Click image to enlarge. Source: Universal Robots “Naturally, what first comes to mind are traditional industrial robots, including articulated arms, parallel robots, and SCARA robots,” Choy said. “These robots boast best-in-class speed, repeatability, and cycle times among most market-available robots.” “That being said, there are difficulties introducing industrial robots into operations,” he added. “They typically require experienced automation engineers to provide solution development, programming, and integration support.” “These robots also need safeguarding and other ancillary automation products, requiring existing production lines to be significantly redesigned to incorporate…

Found in Robotics News & Content, with a score of 19.20

…growth within complete robotic systems for applications such as welding, palletizing, and machine tending, propelled by UR partners creating full solutions powered by our collaborative robot arms.” Sales of UR cobots for integration in OEM (original equipment manufacturer) systems grew about 50% in 2022, said Universal Robots. The company said it began the new year with more than 80 OEM integration partners and over 300 UR+ partners launching application kits and components certified to work with its cobots across industries. Welding a growth area for cobots A significant share of new cobot-powered turnkey systems now handle welding applications, noted Universal…

Found in Robotics News & Content, with a score of 12.80

…Automation noted record deployments and sales, respectively. Mobile robots, welding systems, and software to simulate environments and manage fleets all made it into our top 10 (see right, or below on mobile). It was also a challenging year for robotics vendors and customers, with ongoing supply chain problems and shifting consumer behavior leading to layoffs. Our hearts go out to all those affected so soon before the holidays, but we hope that 2023 is a better year for everyone! To keep up with Robotics 24/7's coverage, be sure to visit our site regularly, and sign up for our free e-mail…

Found in Robotics News & Content, with a score of 6.67

…agency awarded funding to six other organizations including Edison Welding Institute Inc., the University of Houston, and Case Western Reserve University. These projects aim to reduce technological adoption barriers through a joint consortium between various stakeholders. NIST also recently awarded funding to Auburn University’s National Center for Additive Manufacturing Excellence and ASTM International’s AM CoE. They plan to use nearly $1 million to establish a framework that will allow for the identification of critical defects and prediction of fatigue performance within non-destructive evaluation (NDE) data. ASTM International is also developing standards for mobile manipulation and unmanned ground vehicles (UGVs). It…