Editors’ Picks

Found in Robotics News & Content, with a score of 13.61

…these groups and support these important projects.” Projects include welding, grinding, spray coating, automotive, garment manufacturing Automated T-shirt assembly system Principal investigator: Henderson Sewing Machine Company Inc. Project Team: HanesBrands Inc., Apparel Robotics, Southwest Research Institute, Interface Technologies, and MassRobotics Description: The apparel industry is a manufacturing sector that is ripe for automation and a keen strategic focus for ARM. The Institute has funded several robotics projects centered on apparel manufacturing with each building on prior outputs and lessons learned. This project will design, develop, and test a robotic system that automates six operations involved in T-shirt manufacturing to demonstrate…

Found in Robotics News & Content, with a score of 13.51

…to perform critical manufacturing operations such as drilling, laser welding, light machining, and precise assembly. The reason for this is the lack of robotics intelligence required to deliver accuracy, repeatability, and to work in path programming mode rather than point-to-point. This challenge is solved with the xCognition AI-driven control system, Xaba argued. “Our xCognition AI-driven control system opens a new world of application opportunities for industrial robots and cobots,” said Massimiliano Moruzzi, CEO of Xaba. “It positions Xaba at the center of intelligent automation for sustainable manufacturing.” Xaba takes into account the physical world with neural network model Unlike analytical…

Found in Robotics News & Content, with a score of 13.44

…years were spent learning and understanding workflows and processes to improve efficiency and productivity. From running CNC equipment to welding and painting, Buchli has been hands-on in all aspects of bringing products to market. He is also certified in many areas of manufacturing and is a certified Solidworks professional. In addition, Buchli has written the CAMWorks Handbook.

Found in Robotics News & Content, with a score of 13.42

…on the RESURGAM (Robotic Survey, Repair and Agile Manufacture) project and using its expertise to develop underwater friction stir welding technology to help make repairs to ships' hulls safer, faster, and more cost-efficient than conventional welding.

Found in Robotics News & Content, with a score of 13.32

…company will display its GoFa collaborative robot equipped for welding; a live 3D printing demo featuring ABB’s 3D Printing PowerPac for ABB’s RobotStudio simulation and offline programming software; the MiniMAC robotic grinding cell from ABB Value Provider MESH Automation; a vision guided FlexLoader machine tool tending cell; and the Cobot FlexTrainer education cell for interactive classroom training. “ABB has continually developed cutting-edge products and support programs to help a wide variety of manufacturers and their employees become more productive, resilient and adaptable. Our IMTS exhibit will showcase a number of these innovations, many of which have opened up robotic automation…

Found in Robotics News & Content, with a score of 13.24

…the ideal choice for any shop that requires a wide range of parts. Vectis Automation’s Park’N’Arc range extender for welding applications featuring the UR20 cobot. Vectis also showed some of their latest user-experience and ease-of-use cobot welding features including QuickTeach and AI Path Optimization. Hirebotics’ Cobot Welder integrated with Miller’s Auto DeltaWeld, an advanced welder for cobot welding applications. Hirebotics also showed its programming platform Beacon, which now features “Fine Tune,” allowing customers to easily adjust the robot’s torch angles, and “Enhanced Stitch Weld,” a new capability enabling the re-sequencing of stitch patterns.

Found in Robotics News & Content, with a score of 13.05

…automotive, food and beverage industries. This is followed by welding robots which have major applications in automotive industries. Geographically, Asia Pacific is the major market for industrial robots with a share of 55% of the global market revenue. The market is dominated by five countries, with China, Japan, Republic of South Korea, USA, and Germany covering almost 70% of the market. According to the report, China is the main growth driver of this market. According to the report, the major players in the segment are ABB Robotics, KUKA Robotics, Fanuc Corporation, and Yaskawa Motoman Robotics, with 70% of the total…

Found in Robotics News & Content, with a score of 12.88

…into a package at very high speeds. Flexible coordinated welding —This will feature FANUC’s M-900iB heavy-payload material handling robot and two FANUC ARC Mate welding robots. Visual Circular tracking —A FANUC LR Mate 200iD/4S robot uses 2D iRvision to locate random products on a circular conveyor. The cell is equipped with FANUC’s Dual Check Safety (DCS) software, designed to keep operators, robots, and tooling safe. CNC and ROBOMACHINE demos FANUC also said it would demonstrate the following CNC machines and ROBOMACHINEs, including drills, injection-molding machines, and wire electrical discharge machines. They will include the following: FANUC’s visual twin demonstration, which…

Found in Robotics News & Content, with a score of 12.85

…3.2’ x 6.5’ x 3.2’ And compatibility with inexpensive welding wire feedstock “Our Alchemist 1 cell marks the culmination of our extensive relationship with Meltio and FANUC, aimed at expanding the horizons of large format metal 3D printing,” said Xavier Fajardo, CEO of Accufacture. “By offering a standardized, preconfigured solution, we aim to streamline the adoption process for our customers, thereby accelerating innovation across diverse industries.” The pre-integrated Alchemist 1 Cell combines Meltio’s LW-DED (Directed Energy Deposition) head with a FANUC six-axis robot and two-axis positioner within a laser-safe enclosure. Furthermore, the system comes with a complimentary Meltio Space robotic…

Found in Robotics News & Content, with a score of 12.80

…or applications growing in popularity include machine tending and welding. Coupled with the labor shortage and an aging workforce, more and more businesses are starting to see the value of industrial automation. Top shops around the world Many of the top industrial automation providers are based in Asia or Europe, rather than in North America. Some examples include Zurich, Switzerland-based ABB Group and Kitakyushu, Japan-based Yaskawa. They are big companies with employees ranging in the thousands, and each has U.S. offices. The biggest robotics vendors have billions of dollars in annual revenue. As these companies get bigger, so too does…

Found in Robotics News & Content, with a score of 12.80

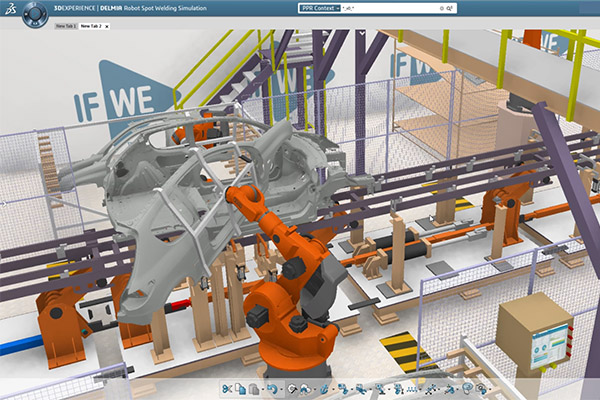

…Automation noted record deployments and sales, respectively. Mobile robots, welding systems, and software to simulate environments and manage fleets all made it into our top 10 (see right, or below on mobile). It was also a challenging year for robotics vendors and customers, with ongoing supply chain problems and shifting consumer behavior leading to layoffs. Our hearts go out to all those affected so soon before the holidays, but we hope that 2023 is a better year for everyone! To keep up with Robotics 24/7's coverage, be sure to visit our site regularly, and sign up for our free e-mail…

Found in Robotics News & Content, with a score of 12.76

…of robot arm tools, including grippers, collision sensors, and welding torches. Materials handling is a big market for EOAT The EOAT market is estimated to increase by $892 million between 2020 and 2025, according to the report “Robotics End-Of-Arm Tooling Market by Application and Geography—Forecast and Analysis 2021-2025” from market research firm Technavio. “Manufacturers have been increasing their investments in industrial robots for assisting in a varied range of activities that human workers or alternative systems are performing,” said the report. “For achieving this, various end-user industries are increasing the adoption of EOAT which can handle multiple sizes, geometries, materials…