Editors’ Picks

Found in Robotics News & Content, with a score of 3.03

The combination of high-density automated storage systems with goods-to-person picking has brought new efficiencies to distribution, especially e-commerce fulfillment. Quite simply, order selectors who can stand in one place to pick can fill more orders than those who have to walk through a facility to do their work. In Mindelheim, Germany, Grob-Werke GmbH & Co. KG, a family-owned manufacturer of machines and assembly systems for manufacturing operations, turned to that same combination to streamline the way it picks and kits materials in a new logistics center to replenish assembly stations in its adjacent manufacturing plant. After all, if you think…

Found in Robotics News & Content, with a score of 3.03

Growing automation capabilities in the manufacturing space coupled with increasing penetration of advanced technologies, such as IoT, RFID, and AI, are expected to drive the material handling equipment market growth. Automated material handling systems are gaining popularity with the growing inclination of industries to replace human labor with automated systems. RFID, IoT, and Automatic Identification & Data Capture (AIDC) technologies are becoming significantly popular as they improve the order fulfillment processes and help in enhancing productivity across the supply chain. As human capital is becoming difficult to retain and recruit, automated material handling solutions are aiding companies in managing the…

Found in Robotics News & Content, with a score of 3.02

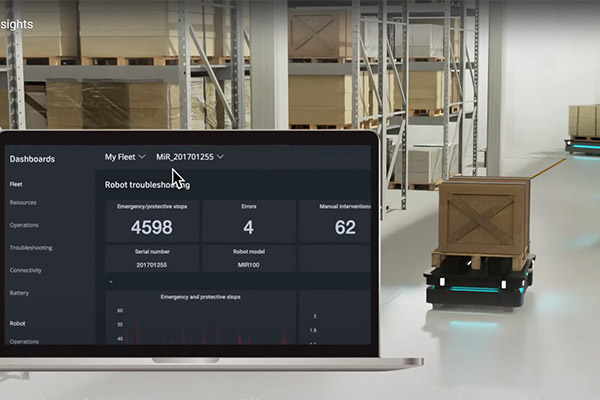

As supply chain operations bring in or add mobile robots, they quickly learn that adding hardware is only part of the process. Integrating and updating software, analyzing data, and building productive partnerships are crucial to ensuring a return on investment, noted industry experts. Robotics 24/7 previously examined how mobile robots can add flexibility to end-user operations. We continued our conversations with the following executives on how companies can get the most out of new or growing deployments: Jane Heffner, vice president of sales at Mobile Industrial Robots (MiR) Jim Lawton, vice president and general manager for robotics automation at Zebra…

Found in Robotics News & Content, with a score of 3.01

Mobile robot providers are continuing to scale up to meet supply chain and e-commerce demand. Locus Robotics Corp. today announced that it has secured an additional $50 million in investment from Tiger Global Management LLC. Wilmington, Mass.-based Locus said it will use the funding to facilitate continued expansion into new markets worldwide, as well as to meet the needs of its growing customer and partner ecosystem. “At a time of increasing volumes and ongoing labor shortages, this new round of funding underscores how critical flexible, scalable, intelligent robotics automation has become to the warehouse and the supply chain,” stated Rick…

Found in Robotics News & Content, with a score of 3.00

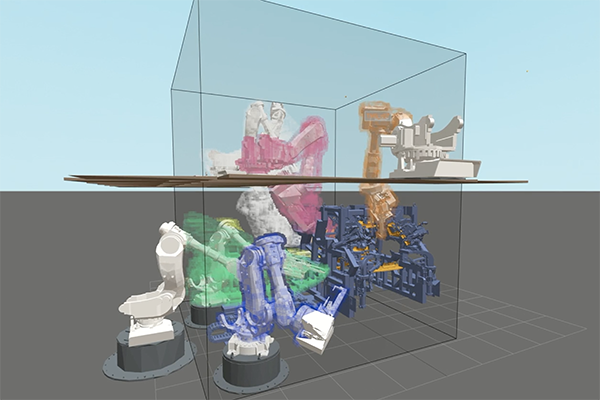

The inability to quickly, easily, and safely deploy industrial robots has been a barrier to entry for new users, but several companies are developing software to change that. Realtime Robotics Inc. today announced that it has completed $31.4 million Series A round of fundraising. The Boston-based company said it will apply the funding to accelerating product rollouts for its autonomous motion-planning technology. With productivity staying flat, and labor representing 60% to 65% of warehouse fulfillment costs, businesses are looking to deliver more with smart automation. Worldwide, companies spend an estimated $350 billion a year on warehousing, and they are increasing…

Found in Robotics News & Content, with a score of 2.98

The market for warehouse automation is exploding because companies with fulfillment operations can’t find enough workers to stick with largely manual processes in the face of rapidly growing e-commerce volumes. At least that's what conventional wisdom posits. That idea has companies looking at autonomous mobile robots (AMRs) and other types of warehouse automation, such as robotic, high-density goods-to-person (GTP) systems, as well as more traditional automation, to do more with less for crucial processes. All of this thinking is true, but it glosses over a fundamental challenge operations face as they implement more automation: getting multiple systems to work together…

Found in Robotics News & Content, with a score of 2.98

Vecna Robotics today announced that it has worked with GEODIS to deploy autonomous mobile robots, or AMRs, for case picking at the logistics company's Indianapolis campus. Starting late last year, the implementation “rethought” human-robot interaction, reduced inefficient travel, and doubled workflow throughput, Vecna said. “GEODIS has been a really amazing, flexible partner with a tech-forward mindset,” said Anthony Moschella, senior vice president of product management at Vecna Robotics. “We have deployed systems together for almost four years, and both recognized a huge unmet need in the market to re-imagine the most common order-picking workflow—case picking—in a way that combines the…

Found in Robotics News & Content, with a score of 2.97

During its “Delivering the Future” event at its robotics manufacturing facility yesterday in Westborough, Mass., Amazon.com Inc. announced Sparrow, its new robotic arm designed to complete product-handling tasks. “Sparrow is the first robotic system in our warehouses that can detect, select, and handle individual products in our inventory,” the company said in a blog post. “Sparrow represents a major advancement in the state-of-the-art technology of industrial robotics. Leveraging computer vision and artificial intelligence (AI), Sparrow can recognize and handle millions of items.” An Amazon spokesperson told TechCrunch the robot can recognize about 65% of the company’s product inventory and takes…

Found in Robotics News & Content, with a score of 2.96

Körber Business Area Supply Chain and Geekplus Technology Co. today celebrated three years of strategic partnership. The companies said the anniversary is “an important milestone in Körber's journey to provide businesses worldwide with efficient, scalable, and sustainable end-to-end logistics solutions.” The partners said they have successfully deployed thousands of autonomous mobile robots (AMRs) in 30 implementations in eight regions. Körber and Geek+ claimed that their joint customers have more than doubled productivity, improved accuracy up to 99.99%, and reduced distances walked by warehouse associates by up to 82%. Customers throughout Europe, America, and Asia-Pacific are currently relying on Geek+'s expertise…

Found in Robotics News & Content, with a score of 2.94

If you wanted to create the perfect mix of conditions to trigger the growth of a type of automated equipment for distribution center operations, you couldn’t do much better than the factors lining up in favor of robotics. E-commerce and omni-channel fulfillment are driving labor-intensive piece picking, and warehouse labor is increasingly difficult to find and retain. DC operators know they need to automate to reduce these challenges, but few operations are able to plunk down millions for traditional automation projects that carry long payback times and might be difficult to reconfigure. Enter a new generation of robots, based on…

Found in Robotics News & Content, with a score of 2.94

As one of the world’s largest manufacturers of cosmetics, skincare, hair care and hair coloring products, L’Oreal operates a number of different types of distribution centers, ranging from facilities that primarily handle full pallets to case and piece picking operations. Each has its own set of demands and approaches to order fulfillment. “What’s impacting our operations the most is the change in order profiles due to the rise of e-commerce,” says Erik Rodriguez, director of supply chain for L’Oreal Americas. “The sheer volume of orders has increased, but the lines per order has decreased. Additionally, there’s pressure from our retail…

Found in Robotics News & Content, with a score of 2.93

Among the combinations of software and hardware for warehouse automation is robotics software and wearable technology. inVia Robotics Inc. and Rufus Labs Inc. yesterday announced a strategic partnership to jointly offer their systems through subscriptions. The companies said the combination of their e-commerce automation, wearables, and workforce analytics is intended to help address labor shortages and improve efficiency and productivity. Founded in 2015, Westlake Village, Calif.-based inVia Robotics said it has developed the “first economical” goods-to-person system through a robotics-as-a-service (RaaS) model. Founded in 2013, Rufus Labs claimed to be the only company to offer industrial wearables and cloud enterprise…