Editors’ Picks

Found in Robotics News & Content, with a score of 6.05

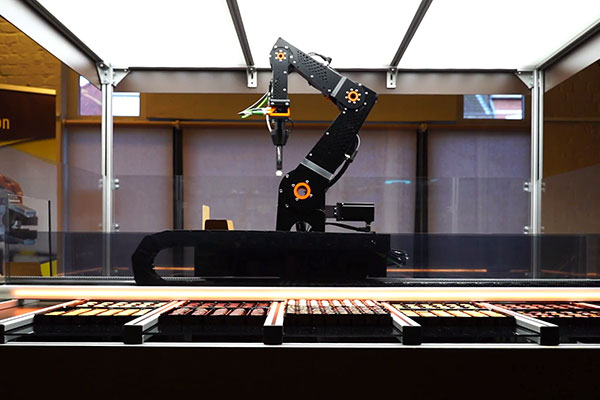

…components in a construction kit. Robots from the Cologne-based plastics specialist igus® – including articulated arm robots, delta robots, and Cartesian vending machines – form the electromechanical framework. This framework can be expanded to include individual components from other manufacturers, such as cameras, GUIs, grippers, motors, sensors, or controllers. With just a few clicks, Roose assembled a robotic solution from these components. Michael Hornung, product manager for drylin® linear and drive technology international at igus®: “Compatibility is guaranteed because our engineers have assembled and tested all components in various combinations. Users thus enjoy investment security.” Robot arm costs only 5,492…

Found in Robotics News & Content, with a score of 12.94

…Houghton Chemical Jessica's Brick Oven L.W. Tank Repair Lee Plastics Lilly's Fresh Pasta Lutco Co. McLane Research Laboratories DOTS Technology Corp. Mission Systems Nevron Plastics and Metals O-D Tool & Cutter Supply Pearl's Premium Lawn Seed Primetals Technologies Quabbin Wire & Cable Raytheon Technologies Rocheleau Tool & Die SalterieOne Sea Salt Sea Trac Systems SiPhox Solvus Global Somerset Industries Spectro Coating Springfield Spring and Stamping TE Connectivity The Catherine Hinds Co. United Cakes Bakery United Paper Box United Plastic Fabrication Vicor Corp. Worthington Assembly Brig. Gen. David Trybula, deputy commanding general of the U.S. Army Combat Capabilities Development Command, served…

Found in Robotics News & Content, with a score of 6.50

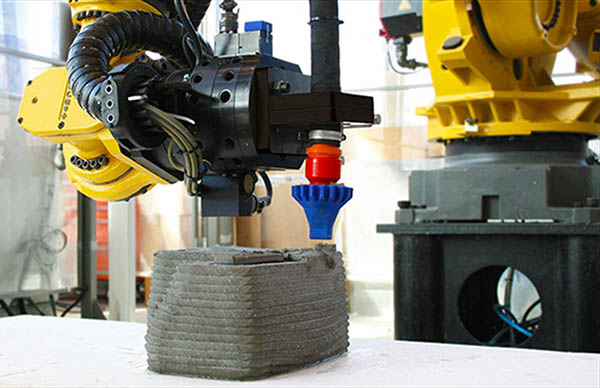

…done the other way around. Layers of material, typically plastic, metal, or ceramic, are used to create these objects. It's highly effective for several reasons. “When you're using additive manufacturing, you'll see that it's often cheaper, especially for one-off builds,” said Jeanette Harrison, a business writer at Elite Assignment Help and OX Essays. “It's also ideal as it creates less waste and ensures you can get items on the market as fast as possible, while still ensuring quality.” 2. Choose the right solvent Once you start planning your 3D printing setup, you'll need to think about the materials that you'll…

Found in Robotics News & Content, with a score of 17.95

…announced that it is participating in the Great Lakes Plastic Cleanup Program with robots and drones. The Midwestern retailer said BeBot and Pixie Drone will help clean up beaches and waterways in partnership with the Council of the Great Lakes Region, or CGLR. “It is a privilege to live near the Great Lakes, which inherently comes with the responsibility to protect them,” said Rick Keyes, president and CEO of Meijer. “Contributing to the conservation of these invaluable waterways is important to the wellbeing of our ecosystems, economy, and the communities we serve.” Grand Rapids, Mich.-based Meijer operates 262 supercenters and…

Found in Robotics News & Content, with a score of 16.03

…link breakages. Richard Habering, Head of Business Unit smart plastics at igus: “Particularly in applications such as automotive production lines with extremely high output, any downtime can cause costs of several €100,000. Real-time status monitoring of the energy supply system in industrial robots, therefore, offers users considerable added value.” Sustainable maintenance with smart plastics With the help of numerous test series in the industry’s largest test laboratory, igus is continuously working on further optimizing the quality and durability of its products. The combination of a triflex R flexible cable carrier with high tensile force absorption and the i.Sense TR.B sensor,…

Found in Robotics News & Content, with a score of 33.32

…and determine the productivity growth of multiple industries, including plastics. Robot density, or the number of robots per 10,000 workers, is approaching 200 in the U.S., according to the International Federation of Robotics (IFR). Robot density is increasing worldwide, as increasingly sophisticated software, robots, and additive manufacturing make production quicker and more efficient. The software development journey typically starts with the creation of the user interface portion, as outlined by Maryville University. Programmers eventually move on to craft the code that processes, analyzes, and responds to the data collected by robots and other systems. Developers must constantly learn about specific…

Found in Robotics News & Content, with a score of 4.86

…to fit into the lowest number of bags, reducing plastic use. Bags are also recyclable, reflecting Kroger's commitment to its Zero Hunger | Zero Waste commitment to rid its communities of hunger and waste. Kroger's end-to-end cold solutions keep groceries fresh once loaded onto customized refrigerated delivery vans, which can store up to 20 orders. Powerful machine learning algorithms optimize delivery routes, considering factors like road conditions and optimal fuel efficiency. Drivers may travel up to 90 miles with orders from facilities to make deliveries. Kroger currently operates customer fulfillment centers in Monroe, Ohio; Groveland, Fla.; Forest Park, Ga.; Pleasant…

Found in Robotics News & Content, with a score of 15.81

…24/7 that Fast Radius is supplying the company with plastics, sheet metal, aluminum, and stainless steel. Tally 3 is the company’s flagship product and is used to check inventory in grocery stores. “Prior to engaging with Fast Radius, and prior to Tally 3, which is our latest production model, we built robots in-house, and we engaged with a multitude of prototype houses in China,” he said. “[They were] very small shops that are able to make low quantities, machining prototype sheet metal that wasn’t always of consistent quality.” A one-stop shop With Fast Radius, Simbe Robotics is able to get…

Found in Robotics News & Content, with a score of 9.48

…parts or products. Wrapping: Robots can wrap products in plastic or other materials. Gluing: Articulated robots apply glue or other adhesives to products. Sealing: They can also seal products in packaging. Welding: From moving and holding items to welding them together, robots are increasingly popular in metalwork. Cutting, folding, and shaping: Pick-and-place robots can manipulate materials such as cardboard or plastic. Die cutting: Like welding, robots are used to die-cut products. Stamping and printing: Pick-and-place robots can stamp or print on products or packaging. Pick-and-place robots are versatile machines that can be used in a variety of settings. They offer…

Found in Robotics News & Content, with a score of 7.17

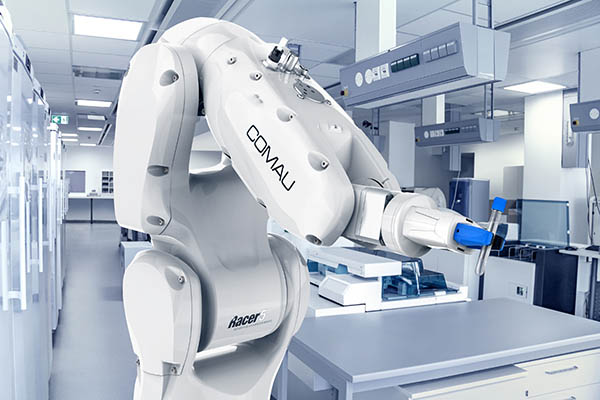

…in fast-growing industries such as food and beverages, pharma, plastic and chemicals, and electronics,” she added. A versatile robot arm The robot arm can be used on a tabletop, inclined, or mounted on a wall or ceiling. Companies can use it to automate applications with stringent requirements such as the handling of pharmaceuticals in sterile filling rooms or the certified cleanroom assembly of microelectronics, while reducing overall operating costs, the company said. Furthermore, Racer-5 SE is well-suited for the food industry, given that its white painted surface is approved for direct contact with all types of food (Reg Eu 1935/2004,…

Found in Robotics News & Content, with a score of 15.40

…followed, with 57,000 installations, +38%. It was ahead of plastics and chemical products, which had 22,500 installations, a 21% increase, and food and beverages, at 15,300 installations, growth of 24%. Source: IFR The Americas and Europe recover In the Americas, the number of industrial robot installations reached the second-best result ever, only surpassed by the record 55,200 installations of 2018. The largest American market, the U.S., shipped 33,800 units, representing a market share of 68%. In 2021, industrial robot installations in Europe recovered after two years of decline, exceeding the peak of 75,600 units in 2018. Demand from the largest…

Found in Robotics News & Content, with a score of 9.31

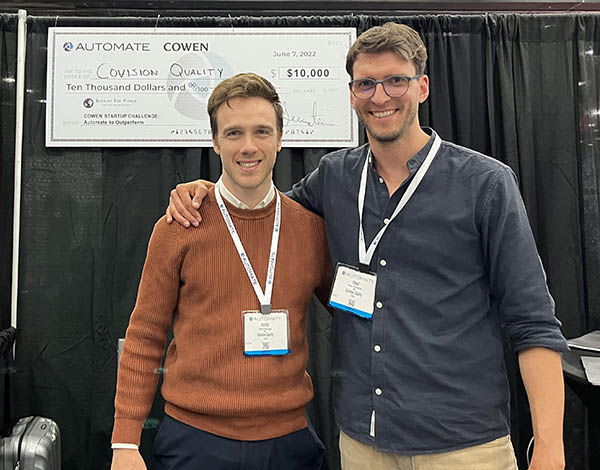

…automates “visual inspection and defect inspection on metals and plastics,” according to its website. The startup is a spin-off of Covision Lab, which is backed by seven multinational technology companies, including Durst, Microtec, alupress, TTControl Hydac International, Microgate, Mirco Photon Devices, and Barbieri. Covision Quality said its customers include manufacturers in the “downstream industry,” including GKN Powder Metallurgy and Aluflexpack. Its partners include NVIDIA, the German AI Association, Tum.ai, and iMAGE S. Covision Quality has made a lot of strides in the nearly three years since its founding, said Franz Tschimben, CEO of Covision Lab. He told Robotics 24/7 that…