Editors’ Picks

Found in Robotics News & Content, with a score of 11.53

…into one operation. The robots handle perishable goods in plastic crates in the refrigerated zones. Although fully integrated with the surrounding manual operations, the system is effectively an island of automation that prepares orders for retail stores, enabling them to be transported to the supermarkets without the need for any further processing. With product pallets going in and store pallets coming out, the island is self-sufficient, taking care of goods reception; put-away; location of stored items; retrieval planning; picking of crates; sorting and assembly of crates into discrete orders; and loading of the orders onto transport units ready for delivery.…

Found in Robotics News & Content, with a score of 11.48

…focused on KyronMax, a group of reinforced polymers with strength-to-weight ratio produced by Mitsubishi Chemical Advanced Materials. “KyronMax engineering plastics are among the most competitive materials in the Mitsubishi Chemical portfolio for metal replacement in structural applications,” says Gerbec. “With Freeform Injection Molding, we can achieve outstanding material properties on an additive platform while using our current feedstocks. We are currently testing KyronMAX’s high-performance property retention when used with FIM technology, and the first results are very promising.” More Info AddiFab Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 11.40

…with Wittmann Battenfeld, a global manufacturer and supplier of plastics processing equipment on July 5, to collaborate on new innovations in liquid silicone rubber (LSR) injection molding. The MoU was signed on behalf of Moldex3D by Dr. Rong-Yeu Chang, CEO and on behalf of Wittmann Battenfeld by David Chen, President of Wittmann Battenfeld Taiwan. The MoU is aimed at bringing together both parties’ extensive knowledge and technical expertise to advance the role of simulation in LSR injection molding. As part of the partnership, Moldex3D has acquired LSR injection molding equipment, including SmartPower 90/350 UNILOG B8 from Wittmann Battenfeld and LSR…

Found in Robotics News & Content, with a score of 10.90

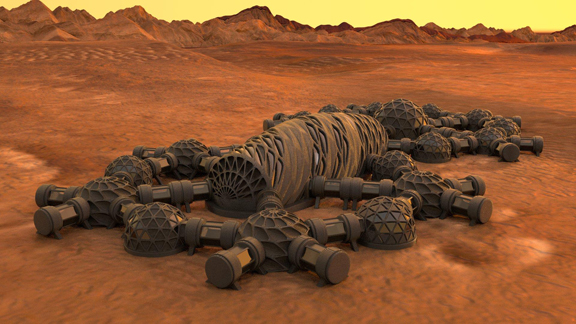

…loose sediment (soil, dust, broken rock, etc.) and recycled plastic. The sediment, known as regolith, can be widely found on Earth, other planets, the moon, and even asteroids ... Based on NASA specifications, Autodesk’s Advanced Consulting team designed the barrier using tools such as Fusion 360 and PowerMill to comply with structural as well as robotic extrusion requirements while achieving significant weight reduction. Autodesk also developed the software to control the industrial robot arm ...” The proof of concept is a success, according to Autodesk. “The first artifact that NASA has printed using this approach is a Jersey barrier—one of…

Found in Robotics News & Content, with a score of 10.87

…chief component. This aluminum has made way for high-performance plastics and high-performance carbon fibers. These high-performance thermoplastics are lightweight and resist high temperatures that lead to fuel optimizations. High-performance thermoplastics are the desired material in large industries such as electrical and electronics and industrial applications. Thermoplastics have seen increasing demand in emerging economies such as India and China. A rousing demand in consumer electronic products has attributed success to market growth in thermoplastics. A rising population on a global scale and increasing disposable incomes has powered demand for these products in end-use industries that include thriving growth for market. A…

Found in Robotics News & Content, with a score of 10.85

…system is designed for order fulfillment and returns processing of items in poly-bags or self-sealing mailer bags. These malleable plastic bags have become the preferred packaging method in e-commerce due to the lower shipping costs versus cardboard boxes. Modex 2020 is scheduled to be held March 9-12 at Georgia’s World Congress Center in Atlanta. The tradeshow will showcase the latest manufacturing, distribution and supply chain solutions in the materials handling and logistics industry. Modern’s complete coverage of the show.

Found in Robotics News & Content, with a score of 10.75

…the Atlas enables AM solutions by printing directly with plastic pellets instead of traditional filament. Image courtesy of Titan Robotics/Jabil. Together, the companies are driving the production of large-format tooling for applications in sheet metal forming, composite layups, welding fixtures, molding, casting patterns and end-use parts on Titan Atlas printers to meet a need for increased part strength and faster printing speeds, companies say. Jabil’s specialized materials science expertise, combined with Titan’s robust printing performance, are ideally suited for addressing the growing list of rigorous industrial, as well as medical, defense and aerospace applications. “Titan and Jabil are fulfilling a…

Found in Robotics News & Content, with a score of 10.69

…a sterile chamber around a 3D printer where unsterilized plastic is brought into the chamber. The possibly contaminated plastic is sterilized by the printing process and packaged maintaining the sterile field. This system was initially designed for a U.S. government agency to allow sterile medical materials to be printed at locations where commonly used sterilization methods might not be possible. “Because this printer can create sterile materials, which are sterile from the inside out once produced, we are eliminating the need for hospitals to resterilize equipment before use,” says Lacaze. “At a time when efficiency and supplies are critical, we…

Found in Robotics News & Content, with a score of 10.69

…in orders from automotive OEMs at 47%, followed by plastics and rubber at 15%, and food and consumer goods at 4%. “We continue to see improvement in the robotics market,” said Jeff Burnstein, president of A3 and RIA. “At this time last year we saw a dip in orders of around 15%, so it’s encouraging to see a recovery through the third quarter. We hope to end the year strong and see growth in 2020 as well.” Burnstein said he sees strong interest in robotics from companies that have never invested in robots before, citing the fact that prospective users…

Found in Robotics News & Content, with a score of 10.42

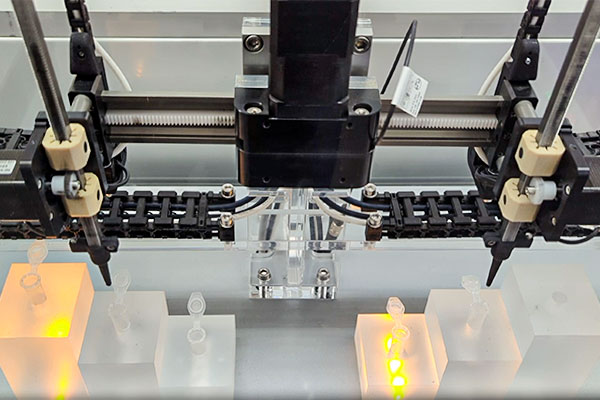

…than $3,000 and offer a 3-month return on investment. Plastic components for automated pipetting Once you’ve made the decision to automate your pipetting processes, the next steps are choosing components & hardware and integrating them. Metal ball bearings are often chosen as part of the guide system for lift and travel movements, however these bearings require constant external lubrication. External lubricants can prove especially challenging in medical applications like pipetting where contamination of samples is a primary concern. Even worse is the potential of total system failure due to inadequate or improper lubrication. Plastic plain bearings completely eliminate the need…

Found in Robotics News & Content, with a score of 10.18

…the past year across almost every industry sector including plastics, metals, medical devices, automotive, pharma, semiconductors, and electronics. With Rapid Machine Operators available by subscription for less than $2,100 per month, manufacturers can increase profits by an average of $110,000 per year for each unit installed, said Rapid Robotics. The RaaS model, which is similar to software as a service and transfers costs from capital expenditures to operational expenditures, enables manufacturers to bid for work that previously would have gone overseas, it noted. “It’s hard to overstate the economic implications of the Rapid Machine Operator,” said Aaron Jacobson, partner at…

Found in Robotics News & Content, with a score of 10.16

…transport & infrastructure. B&R is a solution provider in the automation of machines and factories for industries such as plastics, packaging, food and beverage. The joint commitment to open architecture increases customer choice and flexibility facilitating connectivity in increasingly digitalized industries. On closing of the transaction, B&R will become part of ABB’s Industrial Automation division as a global business unit – Machine & Factory Automation – headed by the current managing director, Hans Wimmer. The co-founders of B&R, Erwin Bernecker and Josef Rainer, will act as advisors during the integration phase to ensure continuity. B&R’s headquarters in Eggelsberg will become…