Editors’ Picks

Found in Robotics News & Content, with a score of 7.37

…quickly study a system’s dominant aspects. Image courtesy of Siemens Digital Industries Software. Starting with a problem that the engineer defines, ML can help streamline optimization of a high number of variables. The workflow begins by using a co-simulation model to create datasets to train a ROM, providing sufficiently accurate results across all of the physics required (Fig. 2). “ROM can improve product design in numerous ways,” says Jenmy Zhang, post-doctoral researcher at Autodesk. “A few examples include reducing overall time to generate many design possibilities, predicting part performance on the fly during interactive design and product performance probabilistic sensitivity…

Found in Robotics News & Content, with a score of 40.79

Siemens Digital Industries Software is expanding its ecosystem for industrial additive manufacturing (AM) through partnerships with Morf3D, Sintavia and Evolve Additive Solutions. Through these new partnerships, Siemens is adding support for new methods of AM production, further strengthening Siemens’ end-to-end solution for industrialized additive manufacturing as part of its Xcelerator portfolio of software and services. Working with Sintavia, Morf3D and Evolve Additive solutions can strengthen Siemens’ end-to-end industrial AM solution while expanding support for service providers and AM machine builders, Siemens says. Siemens is collaborating with Sintavia, a metal additive manufacturer, to connect all phases of the AM process and…

Found in Robotics News & Content, with a score of 14.94

…additively manufacturing parts. The consortium includes Equinor, Saudi Aramco, Siemens, Kongsberg Maritime, Voestalpine, Guaranteed, IMI CCI, Kongsberg Ferrotech, Addilan, BMT Aerospace, FIT AG, Howco Group, ImphyTek Powders, Intertek, XDM3D and ExOne. In February, the consortium released a new standard, “Additive manufacturing of metallic parts” ( DNVGL-ST-B203) for the oil & gas sector, which is focused on wire-arc additive manufacturing (WAAM) and laser-based powder bed fusion (PBF-LM). The group is expanding its effort to incorporate more AM technologies, such as binder jetting technology (BJT). “As manufacturers around the world move to new additive manufacturing technologies, it’s important that they have standards…

Found in Robotics News & Content, with a score of 11.94

…the digital twin,” Kasper adds. Orchestrating engineering and operations Siemens has included service lifecycle management in its industrial software portfolio for many years. “Our strength has always been product configuration, understanding how an asset or a plant is configured,” says Yishai Barak, director of service lifecycle management, at Siemens Digital Industries Software. “But this is not the same as service operations. Without consideration of the physical asset in the digital model, you don’t have the full story.” Siemens then retired a few software products from their order book and set about to create a service operations platform that combined partnerships…

Found in Robotics News & Content, with a score of 4.07

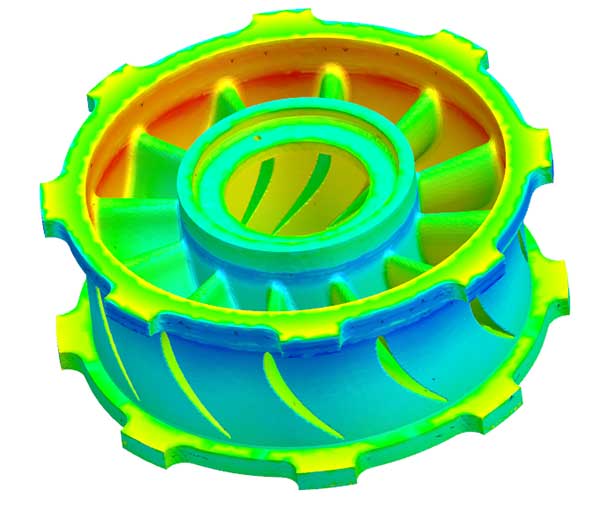

…with traditional CNC machining, casting and injection molding processes. Siemens Digital Industries Software has incorporated generative design and topology optimization capabilities into its NX platform to make the capabilities more accessible while adding an array of features designed to help teams optimize AM output. NX’s convergent modeling technology delivers unified 3D modeling, allowing engineers to easily collaborate and work between facet and B-rep data, creating a more integrated design workflow that results in lighter weight components that don’t sacrifice design intent or integrity. Additionally, the company’s Simcenter 3D AM Process Simulation suite and the AM Path Optimizer integrated into NX…

Found in Robotics News & Content, with a score of 7.25

…businesses, including National Sponsors Salesforce, PTC and Microsoft and Platinum Sponsors Walmart and ABB. Other sponsors include Gold Sponsors Siemens, Polaris and Emerson; Silver Sponsors NIST Manufacturing Extension Partnership, Kronos, Ceridian and Plex; State Sponsors Ohio MEP Network and Ohio Manufacturers' Association; and Industry Sponsors The Plastics Industry Association and Alliance for Automotive Innovation. Additional sponsors include Stanley Black & Decker and Marvin. Sources: Press materials received from the company and additional information gleaned from the company’s website.

Found in Robotics News & Content, with a score of 28.23

…Demonstrator, is striking yet another partnership, this time with Siemens Digital Industries Software to advance development using digital twins. VSI Labs, which researches active safety and AV technologies, is partnering with Siemens, using its PAVE360 platform to create digital twin simulations for the validation and testing of all the processors, electronics, sensors, and systems that are powering the VSI Labs Capability Demonstrator. The latter is an advanced AV development vehicle equipped with components from best-in-class automotive technology leaders, including ARM for processors, NXP for the central compute platform, FLIR for thermal cameras, and Dataspeed for a by-wire control systems, among…

Found in Robotics News & Content, with a score of 35.72

Siemens and Nexa3D have announced a collaboration designed to bring Nexa3D’s additive manufacturing production systems up to full Industry 4.0 preparedness. This partnership highlights both companies’ commitment to help additive manufacturing prepare for Industry 4.0 with collaborations, open architecture and predictive serviceability. Having worked side by side with automotive, aerospace, medical and industrial customers, Siemens and Nexa3D have worked to combine connectivity, digital twin sensing and data acquisition to deliver predictive maintenance, process monitoring and print optimization to deliver polymer additive manufacturing solutions at scale on the factory floor, the companies report. Under this collaboration, Nexa3D’s entire Quantum Laser Sintering…

Found in Robotics News & Content, with a score of 32.89

Siemens Digital Industries Software and VSI Labs, a researcher of active safety and autonomous vehicle (AV) technologies, are partnering to further advance development of self-driving car technology. Through the partnership, Siemens’ PAVE360 platform will be used to create digital twin simulations for the validation and testing of all processors, electronics, sensors and systems powering the VSI Labs Capability Demonstrator—an advanced AV development vehicle equipped with components from automotive technology leaders and integrated by VSI solutions engineers. “The primary objective of this partnership is to demonstrate equivalence between Siemens’ industry-leading digital twin technology and a physical platform, thereby increasing confidence in…

Found in Robotics News & Content, with a score of 13.10

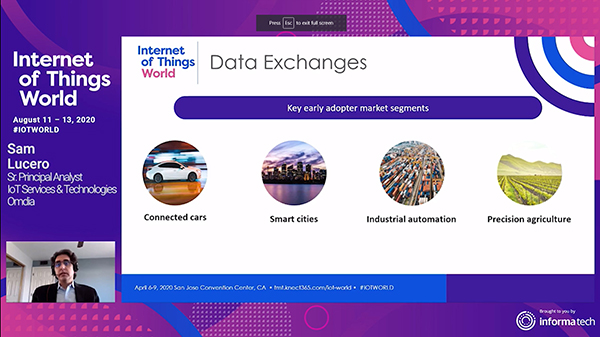

…Source Seshagiri Marellapudi, head of MindSphere IIoT Cloud Platform, Siemens, also pays attention to data, as the backbone of Industry 4.0 transformation. In his presentation, he said, “It's all about how you pull the data from your industrial systems, what you can do with it, and how you produce actionable insights.” MindSphere, he proposes, is a good solution to connect your physical device to the digital counterpart to create a closed loop digital twin lifecycle. In the digital simulation of a factory's operation, for example, “there are often opportunities to improve the production line in reality. Can you create these…

Found in Robotics News & Content, with a score of 40.46

…planning data for automation and switching technology products from Siemens via its platform for 3D CAD models. Users of Siemens PLM solutions will now have direct access to digital Siemens components such as switches, controls, relays etc., which are available within Siemens NX, Solid Edge, Teamcenter as well as the CADENAS portal, enabling engineers to quickly integrate them into their product designs. CAD Data as Step Toward Industry 4.0 “Siemens plays a pioneering role when it comes to comprehensively representing constructions as digital twins. Intelligent, native 3D CAD data of the individual components are required to simulate and optimize the…

Found in Robotics News & Content, with a score of 8.38

…that’s brought a lot of assurance for our customers.” Siemens, which markets AM simulation software in addition to its Additive Manufacturing Network, an online order-to-delivery collaboration platform for industrial AM, is addressing the security challenges related to 3D printing in various ways. Officials see the digitalization of the design-to-production process as creating new opportunities to address longstanding traceability issues, whether the production method is 3D printing or traditional practices like computer numerically controlled (CNC) milling, according to Aaron Frankel, vice president of Siemens’ additive manufacturing software program. Early in the design cycle, users of NX can specify rules for CAD…