Editors’ Picks

Found in Robotics News & Content, with a score of 17.03

…Yaskawa. FANUC's robots serve in many industrial applications, including welding. Source: FANUC FANUC a global robotics leader With over 900,000 robots sold, FANUC claimed that it is the world’s largest manufacturer of industrial robots. The company has been active in factory automation since 1955. It is headquartered in Oshino, Japan, where FANUC produces its robots in highly automated factories at the base of Mount Fuji. FANUC America is based in Rochester Hills, Mich. FANUC produces more than 100 models of robots, most of which are distinctively yellow. They range from large and small articulated robots for handling and welding to…

Found in Robotics News & Content, with a score of 16.89

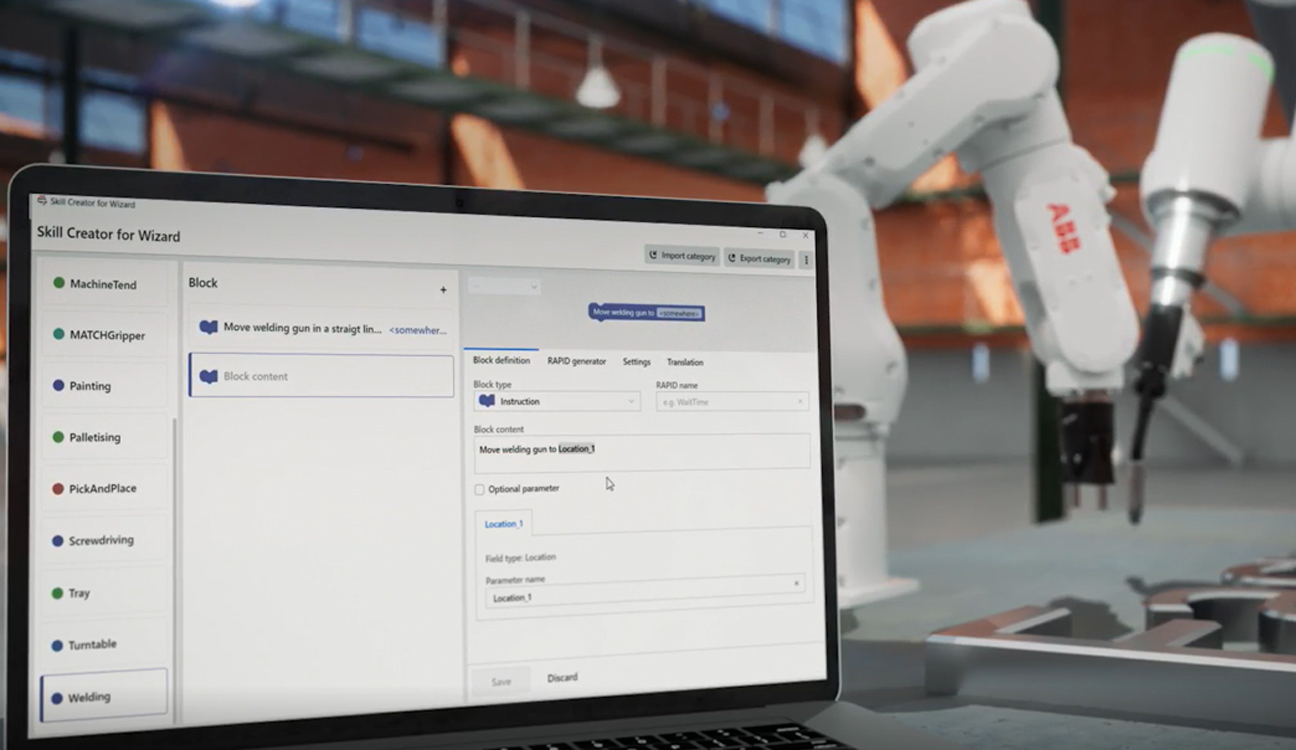

…prior training to develop robot applications such as arc welding or machine tending. It also increases operational flexibility, allowing users to modify existing programs and pre-programmed blocks that control various behaviors, ranging from robot movements to signal instructions and force control, through its intuitive graphical user interface. Catering to novice and experienced users, Wizard Easy Programming comes with Skill Creator, a tool that helps system integrators and other expert users efficiently create customized, application-specific Wizard blocks for their customers' use. Skill Creator can simplify the creation of highly-specific tasks like machine tending and welding as well as intricate applications such…

Found in Robotics News & Content, with a score of 16.75

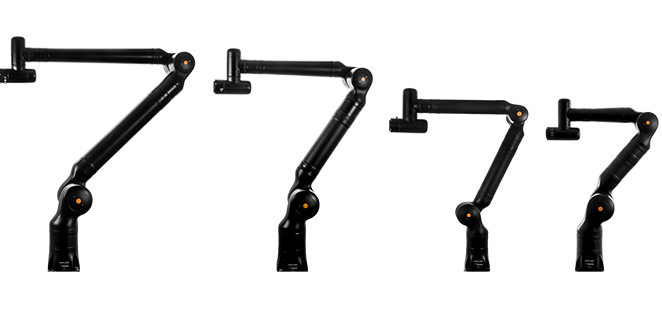

…to handle because of their flexibility, including machine tending, welding, dispensing, and palletizing.” Collin Ayres recently joined the Kassow Robots team after receiving his mechanical engineering degree from the University of Nebraska, Lincoln. As Regional Channel Partner Manager, he focuses on helping Kassow Robots expand its presence in North America and supporting sales partners in the western part of the country. The latest addition to the U.S. team is technical support engineer Chris Hapsias. He is responsible for providing technical support and training for Kassow Robots’ U.S. distributor network. He brings four years of factory automation experience, specifically in the…

Found in Robotics News & Content, with a score of 16.55

…including electronics, automotive, aerospace, and metal fabrication.” Applications include welding, inspection, and additive manufacturing ABB said its Ultra Accuracy feature meets the demands of applications where exact positioning is crucial for maintaining product quality and operational efficiency. Additional benefits include the combination of precision with speed and a full range of motion. The company said manufacturing applications Ultra Accuracy can support include: Gluing and sealing in consumer electronics production Laser welding of automotive parts to tight tolerances Composite material layering in aerospace manufacturing Precision laser cutting in metalwork fabrication Layer positioning in additive manufacturing and 3D printing Performing precision quality…

Found in Robotics News & Content, with a score of 16.53

…provides automation products and solutions for application including arc welding, assembly, coating, dispensing, material handling, material cutting, material removal, packaging, palletizing, and spot welding. Construction projected to be completed by June 2024 The company said it will create 70 new jobs as part of the addition. Four hundred employees work at the facility now. Yaskawa Motoman plans to begin the construction process in June 2023. Construction is expected to take approximately twelve months, with a projected completion date of June 2024. “When we built our current 305,000 square-foot headquarters and manufacturing facility in 2011, we purchased additional land to support…

Found in Robotics News & Content, with a score of 16.26

…cobots will help BlueBay customers with applications including palletizing, welding, and packaging for light manufacturing, automotive, and electronics. Kassow KR cobots have long reach Kastrup, Denmark-based Kassow Robotics said its line of five seven-axis collaborative robots offers speed, power, and a long reach. The company added that its cobots, plus simple programming techniques, can help customers and integrators quickly and cost-efficiently automate complex tasks in machine tending, material handling, general automation, and related applications. The KR series provides a reach of about 3 to 6 ft. (850 to 1,800 mm) and payloads around 11 to 40 lb. (5 to 18…

Found in Robotics News & Content, with a score of 16.16

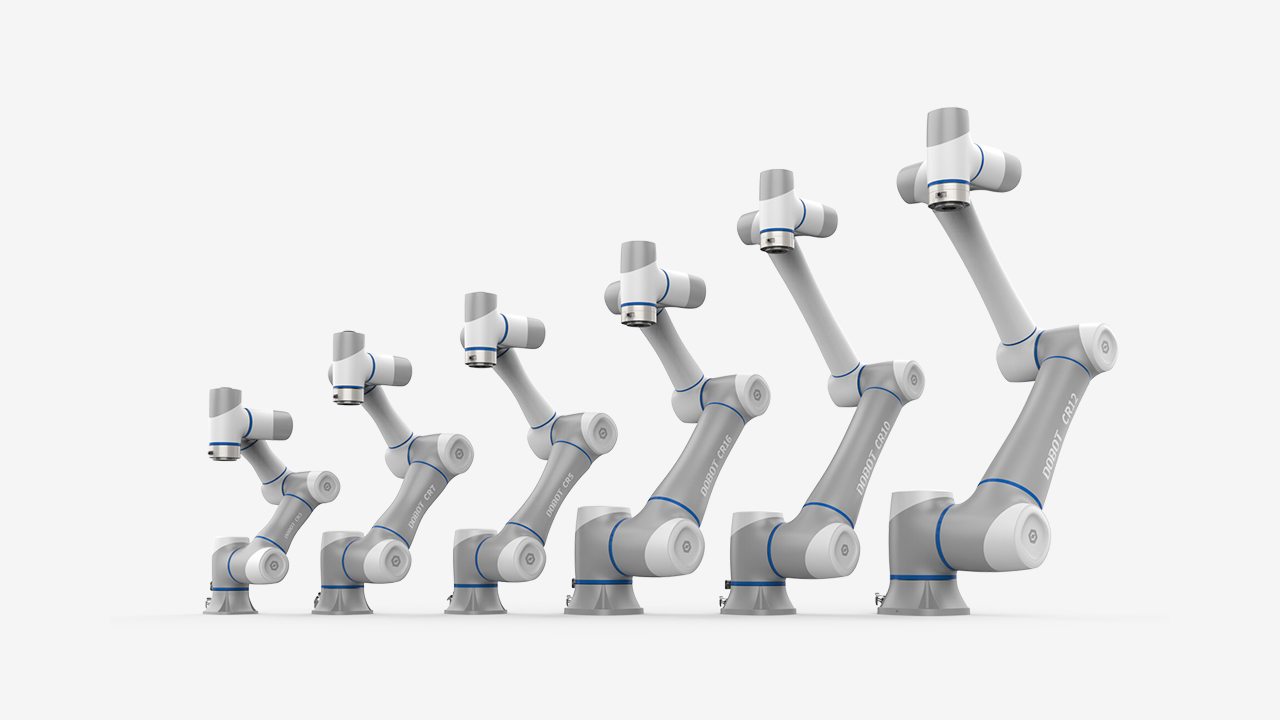

…palletizing, as well as large-sized workpiece machining and long-seam welding in complex scenarios. Hannover Messe is hosted and organized by Deutsche Messe AG. This year's industrial trade show runs from April 17 to April 20 and features more than 2,500 exhibitors and some 66,4000 attendees. CR20A has minimal residual vibration Based on new-generation technology and advanced dynamic algorithms, the CR20A's residual vibration is reduced by 50% during high-speed stops and has enhanced reliability to greatly improve production efficiency in heavy-load scenarios, the company said. Dobot noted it has developed dedicated process package software for palletizing, welding, and other complex tasks.…

Found in Robotics News & Content, with a score of 16.05

…simulation applications that incoperate its technology, among them a welding simulator and an automotive body painting simulator from Lincoln Electrics and Honda. Aimed at providing industrial skills training, the simulation systems incorporate not just immersive visuals but also physical props—replicas of weld guns and spray paint guns used in real operations. The appeal for the use of ARVR training comes from the expected cost savings. Generally skill training in welding or spray painting in VR costs a lot less since it doesn't require a specialized location, vehicle components to test-paint, or cleanup operations. The use of replica equipment instead of…

Found in Robotics News & Content, with a score of 16.02

…our cobots in demanding applications like heavy palletizing and welding. This collaboration with Bota Systems increases the sensitivity and precision of solutions with UR, giving our customers the tools they need to innovate and automate more effectively.” By removing the need for an adapter, Bota Systems says it reduces the overall weight of the sensor assembly. The company says this drop in weight allows users to fully utilize the robot’s payload for material handling rather than merely supporting end-of-arm tooling. Additionally, eliminating adapters reduces the risk of using inappropriate materials that could compromise sensor stiffness and affect measurement accuracy. “The…

Found in Robotics News & Content, with a score of 15.88

…equipment. Companies that won grants include Springfield, Mass.-based Advance Welding, which received $250,000 “to expand their welding capabilities,” Nolan said. “They’re now one of the most well-rounded fusion welding shops in the country,” Nolan said, noting the company recently purchased East Windsor, Conn.-based KTI Inc., an electron beam welding and laser beam welding business. “We’ve actually seen some suppliers in Massachusetts already move their welding to advanced welding,” Nolan said. “We love to see that.” Other companies featured include Avon, Mass.-based MassRobotics partner AccuRounds and Fall River, Mass.-based Klear Vu Home Textiles. Southco shows off its products at MassRobotics' RoboSource:…

Found in Robotics News & Content, with a score of 15.58

…help to reinforce that.” CL series cobots fitted for welding, finishing, and palletizing Designed and built in Germany, and powered with NEURA Robotics’ robot assistance technology, the CL series can run at a speed of 200 degrees per second with repeatability of +/- 0.02 millimeters, or 0.0008 inches. Payloads and reaches include: 3 kilograms at 590 millimeters, or about 6.6 pounds at 23 inches 5 kilograms at 800 millimeters, or about 11 pounds at 31 inches 8 kilograms at 1300 millimeters, or about 17.6 pounds at 51 inches 10 kilograms at 1000 millimeters, or about 22 pounds at 39 inches…

Found in Robotics News & Content, with a score of 15.40

…products. Sealing: They can also seal products in packaging. Welding: From moving and holding items to welding them together, robots are increasingly popular in metalwork. Cutting, folding, and shaping: Pick-and-place robots can manipulate materials such as cardboard or plastic. Die cutting: Like welding, robots are used to die-cut products. Stamping and printing: Pick-and-place robots can stamp or print on products or packaging. Pick-and-place robots are versatile machines that can be used in a variety of settings. They offer a number of advantages, including reduced labor costs, flexibility, and improved safety. When selecting a pick-and-place robot, it is important to consider…