Editors’ Picks

Found in Robotics News & Content, with a score of 1.88

…to the customer doorstep. We also needed visibility into inventory.” “We had been in touch with Fetch way before this,” noted Best. “Since it's also an American company, we wanted them to be onsite.” Zebra scanners, Fetch AMRs are complementary Zebra Technologies said its ecosystem includes more than 10,000 partners across over 100 countries. The Lincolnshire, Ill.-based company claimed that it serves customers of all sizes—including 84% of the Fortune 500—with hardware, software, and services to digitize and automate workflows. Zebra recently expanded its industrial automation portfolio with its $290 million purchase of Fetch Robotics. It also increased its machine…

Found in Robotics News & Content, with a score of 1.85

…supply chain management software that streamlines the flow of inventory and information from supplier to store shelf. With approx. 440 employees worldwide HighJump supports more than 4,000 customers in 66 countries, ranging from SME business to marquee global enterprises. HighJump’s functionally rich and highly adaptable end-to-end solutions efficiently manage customers' warehousing, manufacturing, transportation, distribution, delivery routes, and retail stores. About Körber Logistics Systems The Business Area Logistics Systems, belonging to the international technology group Körber and based in Bad Nauheim, Germany, is the leading provider of fully integrated applications for the optimization of complex internal and external logistics processes. Under…

Found in Robotics News & Content, with a score of 1.81

…We’re even seeing camera-mounted drones being used to take inventory in the warehouse. Kroger, Walmart, Macy’s, Target and Coca-Cola are just a few leading companies that are testing and investing in the next generation of advanced warehouse automation. Their use is the next logical step to leverage efficiencies in supply chains that are already under severe pressure to speed up order fulfillment and reduce costs. While investing in advanced automation might seem to be the best way to manage fulfillment, the analysis to determine the best fit and return on investment is often insufficient or influenced by the automation and…

Found in Robotics News & Content, with a score of 1.80

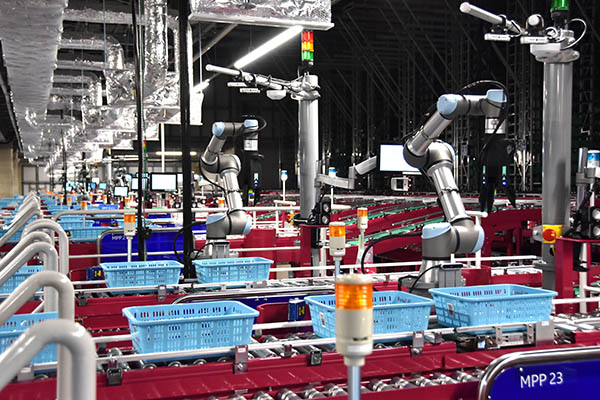

…called on to store, move, pick, put-away and sort inventory in more warehouses and DCs. At least for now, it’s the early adopters that are jumping into the fray, namely due to budgetary and cultural challenges associated with the shift. However, much like we see with any disruptive innovation, as the technology improves and becomes less pricey—and as more people get used to the idea of robots in the warehouse—adoption rates are likely to grow exponentially. Pretty far along the path Intent on improving productivity, increasing order accuracy, reducing safety incidents and/or speeding up cycle times, a growing number of…

Found in Robotics News & Content, with a score of 1.80

…importance of safety, particularly in public-facing environments. “If an inventory-scanning robot hits an employee stacking a shelf, that's an OSHA call, but what happens if it hits Grandma?” said Prather. “It's one of the big concerns for retail end users.” Still, despite different use cases, adoption by multiple industries could lead to more direction for developers. “What do we want out of the technologies? My needs in a FedEx operation are different than what manufacturers or retailers may want, but we use similar mobile robots,” Prather said. “We can flip the script from robotics manufacturers just trying to sell stuff.”…

Found in Robotics News & Content, with a score of 1.77

…to maximize productivity, speed, accuracy, and safety in end-to-end inventory fulfillment operations,” he said. One area where AMRs are particularly valuable is the flow of pallet-sized loads. Such workflows are continuous, complex, and often difficult to manage, but they make up the bulk of the costs and time for warehouse personnel. Moving pallets is thus a perfect application to automate. “Companies are deploying fleets of AMRs—alongside humans—to automate various pallet movements, which increases reliability, safety, and productivity without significant changes in infrastructure,” said David Griffin, chief sales officer at Seegrid. “Furthermore, given the flexibility of AMRs, fleets can fit into…

Found in Robotics News & Content, with a score of 1.77

…are all about better fulfillment. There’s the range of inventory that the robots can handle, an expected rate of picking, targeted order integrity and an expected autonomy for the robots. “Ultimately, it’s about the reliability and accountability of the robots. They must enhance the flow and the process,” said Jentoft. Kishore Boyalakuntla, vice president of products at Berkshire Grey, cited FedEx as a company that built its robotic solution to KPIs. The carrier uses robots to handle small packages at several regional hubs. Ted Dengel, managing director of operations technology and innovation at FedEx, said each robotic system sorts 1,000…

Found in Robotics News & Content, with a score of 1.74

…better fulfillment, said RightHand's Jentoft. There’s the range of inventory that the robots can handle, an expected rate of picking, targeted order integrity, and the expected level of autonomy for the robots. “Ultimately, it’s about the reliability and accountability of the robots,” he said. “They must enhance the flow and the process.” Kishore Boyalakuntla, vice president of products at Berkshire Grey, cited FedEx as a company that built its automation to KPIs. The carrier uses robots to handle small packages at several regional hubs. Ted Dengel, managing director of operations technology and innovation at FedEx, said each robotic system sorts…

Found in Robotics News & Content, with a score of 1.74

…be expecting 1,000 orders of a hot toy against inventory in high-bay storage. They need a pallet as quickly as possible.” “While our robots aren't managing pallets, they can help with other demand around presale orders, such as adding a toothbrush or a flashlight to an order,” he explained. “It's a complex long tail, with people marrying orders. It's really about the flow management system.” 4. inVia Logic guides robots plus people “We recently went live with our software guiding customers' forklifts just like our robots,” Elazary said. “Two people would choose the same aisle and get stuck, but inVia…

Found in Robotics News & Content, with a score of 1.72

…doors. The need to cater to an increase in inventory ahead of the withdrawal date is unfortunate, but it is leading people to reconsider their storage strategies and to start planning for the future. This head start could make British businesses more competitive in the long run and set the UK up for a rosier future. Read: The Difference between a Traditional Warehouse and an OmniChannel Warehouse About the Author James Beale is Operations Manager at Invicta Pallet Racking. For over 25 years Invicta has been at the forefront of the archive storage industry throughout the UK and Europe, designing…

Found in Robotics News & Content, with a score of 1.70

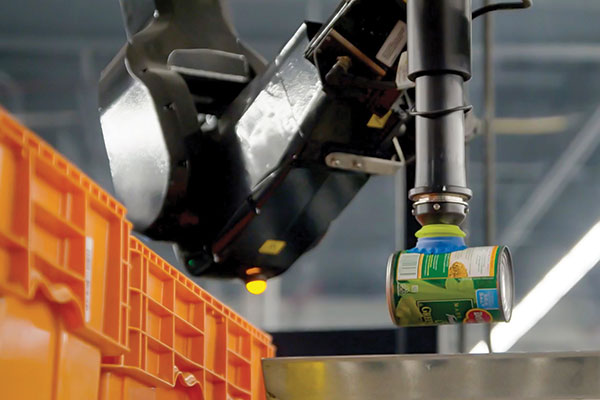

…worker productivity, reduce error rates, and reduce frequency of inventory checks. Robots can also optimize picking, sorting, and storing times and increase access to difficult or dangerous locations. Food manufacturing and food processing: Primary processing and secondary processing applications are increasingly using industrial and collaborative robots. The introduction of more advanced grippers has boosted robotics applications within the food-processing industry. These grippers allow for quick but gentle handling of sensitive food products like fruit and vegetables. Robots can also be used to automate food packaging and food delivery, with companies such as Marble [acquired in 2020 by Caterpillar] and Dispatch…

Found in Robotics News & Content, with a score of 1.70

…parts, because they won’t have the carrying cost of inventory or have to create new tooling or change over production lines.” Space is also an issue for organizations that have a large part catalog. “There are these huge warehouses full of shelves of tooling, and if they need a part, they pull out the tooling and stamp out parts,” adds Jonah Myerberg, chief technology officer of Desktop Metal. “We’re seeing a shift away from that kind of traditional factory and toward a digital factory that uses software to make the parts on demand. They are never obsolete and they don’t…